To elaborate on my post,

@Downwindtracker2's comment about the Taiwanese belts not matching North American belts is accurate, I believe. I have a Taiwanese lathe and milling machine, both built in 1989. The lathe appears to have its original belts, while the Sanwu-branded belts on my milling machine are most likely original as well. However, the Napa-branded belt is definitely not original obviously.

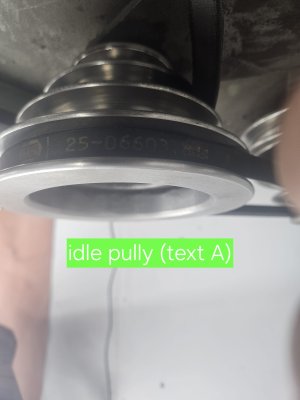

I'm beginning to suspect that the Napa belt was purchased to make belt changes easier, as it doesn't match the correct belt width and I suspect it to have a slightly larger circumference than the factory belt. Both my lathe and mill use belts labeled B34, and in fact, both belts on the lathe are also labeled B34 one Belt on the Mill is a B34

I went to Gregg Distributors and bought the belts listed by

@YYCHM for my mill, which matched the specifications in my manual. I also purchased two B34 belts for my lathe. I started with my lathe because it was in desperate need of new belts. I removed the B34 from the motor and replaced it with the new B34 from Gregg Distributors, but it was way too big. Even with the full tension adjustment, it wouldn't fit.

Next, I removed the B34 from my mill and tried putting the new B34 from Gregg Distributors in its place, but it was also too big. However, when I put the original B34 from my mill on the lathe, it fit perfectly.

I know the logical next step would be to measure the belts and buy the correct ones based on those measurements, but at the time, my thinking was that by purchasing the belts specified in the manuals, I could eliminate any doubts about whether the current belts were actually the right ones. I was hoping for a one-trip solution (but, of course, it never works out that way, does it?).