I fight with this $#&@ thing every time I use it. I need to bolt a plate to the side of the quick change and clamp it to the compound to keep it from rotating on the tool post, Does anybody have a Knurling tool they like? Style, Type? I need something big enough for a 14 inch lathe.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool My most hated tool

- Thread starter Don Sipes

- Start date

Tool

This is the style I was thinking of.

There must be others out there that aren't charging for plans but this looks like a good one.

Knurling Tool - HomemadeTools.net

Build this Knurling Tool that eliminates the end thrust on your cross feed screw and cross feed nut, this tool will knurl up to 2" diameter stock,

www.homemadetools.net

Former Member

Guest

I have knurl on my Logan lathe with only a 1/2 hp motor.

I find the best result comes from gradually increasing pressure and depth of cut on multiple passes. Too deep is just hard on everything.

Oh one other thing lots of oil and in this case there is no such thing as too much.

I find the best result comes from gradually increasing pressure and depth of cut on multiple passes. Too deep is just hard on everything.

Oh one other thing lots of oil and in this case there is no such thing as too much.

yeah, get rid of those pressure knurlers, bin 'em, toss 'em, recycle 'em....yuck and your lathe likes them even less.

The scissor style work well. Crank it up, no undo pressure on any lathe parts and a full knurl in one pass.

Best are cut knurling tools. Run them at speed and get great knurls in a single pass.

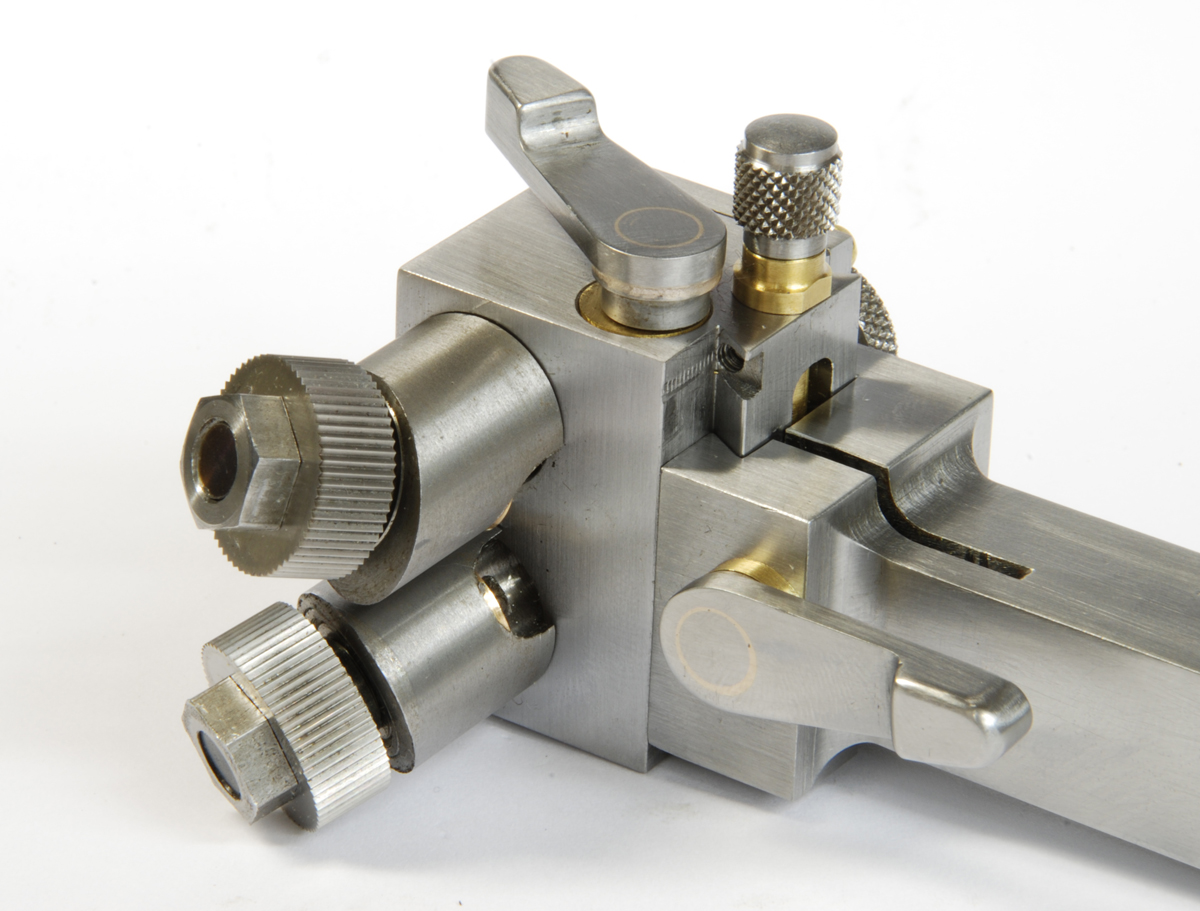

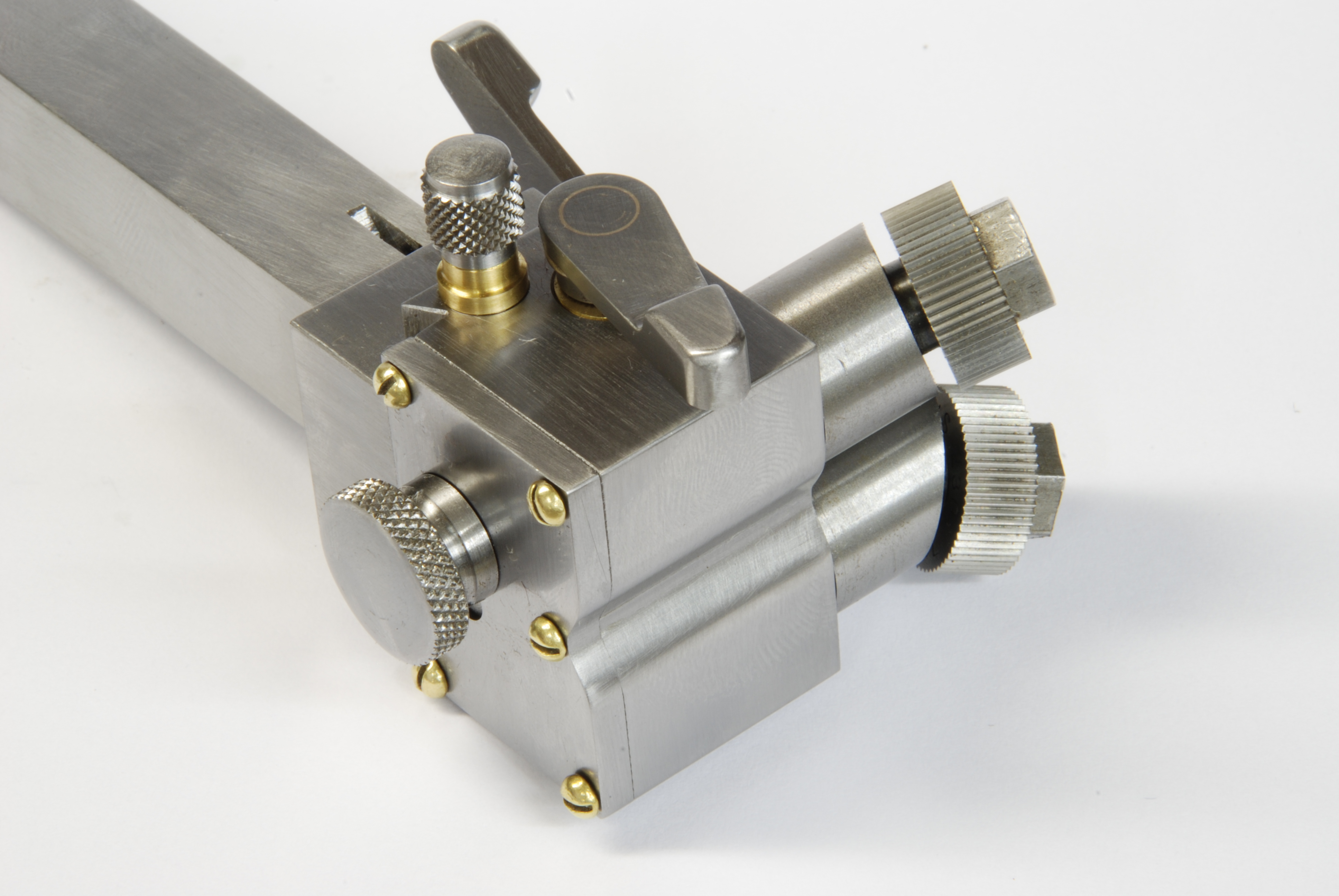

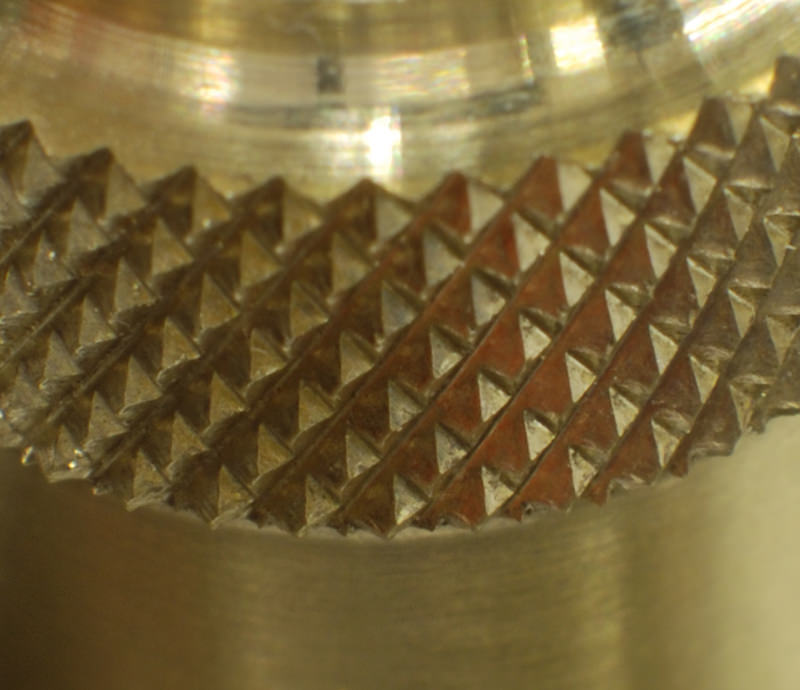

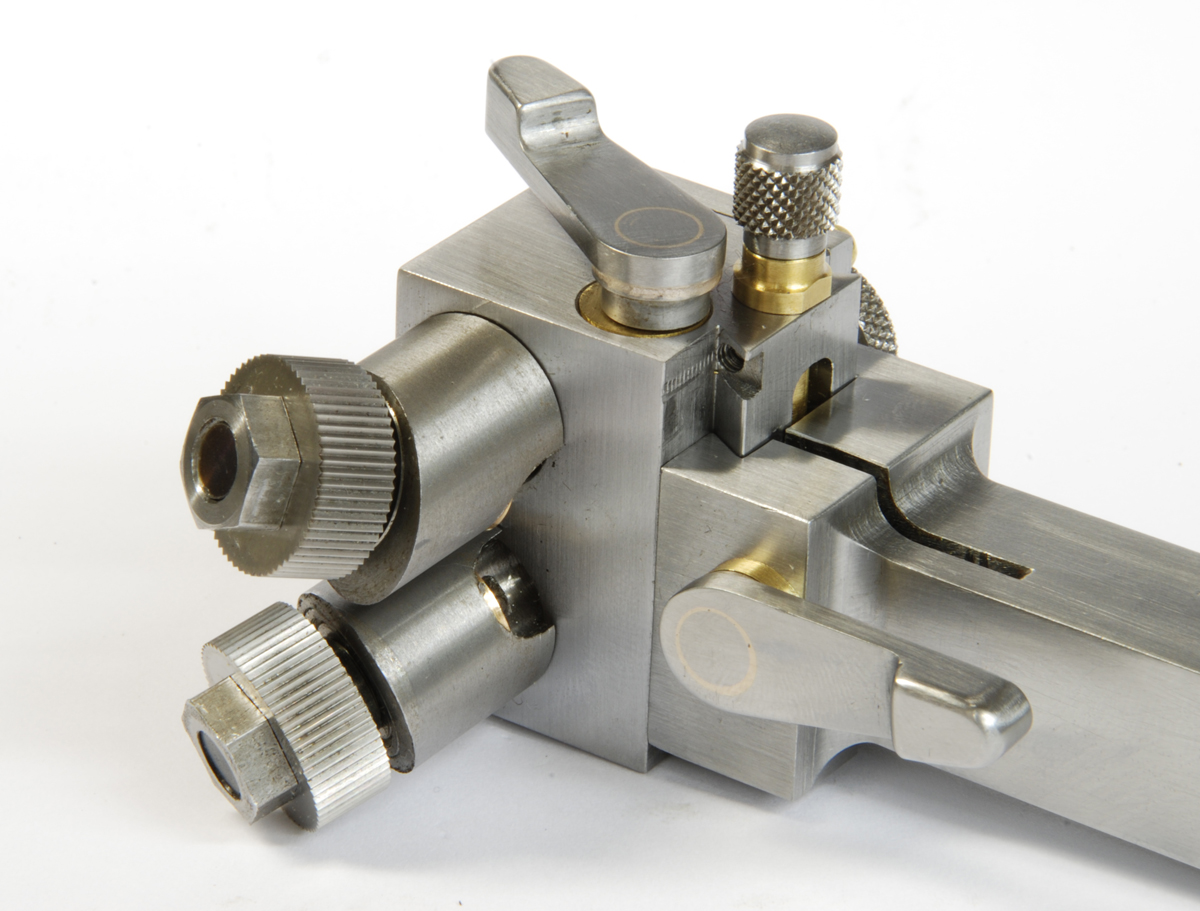

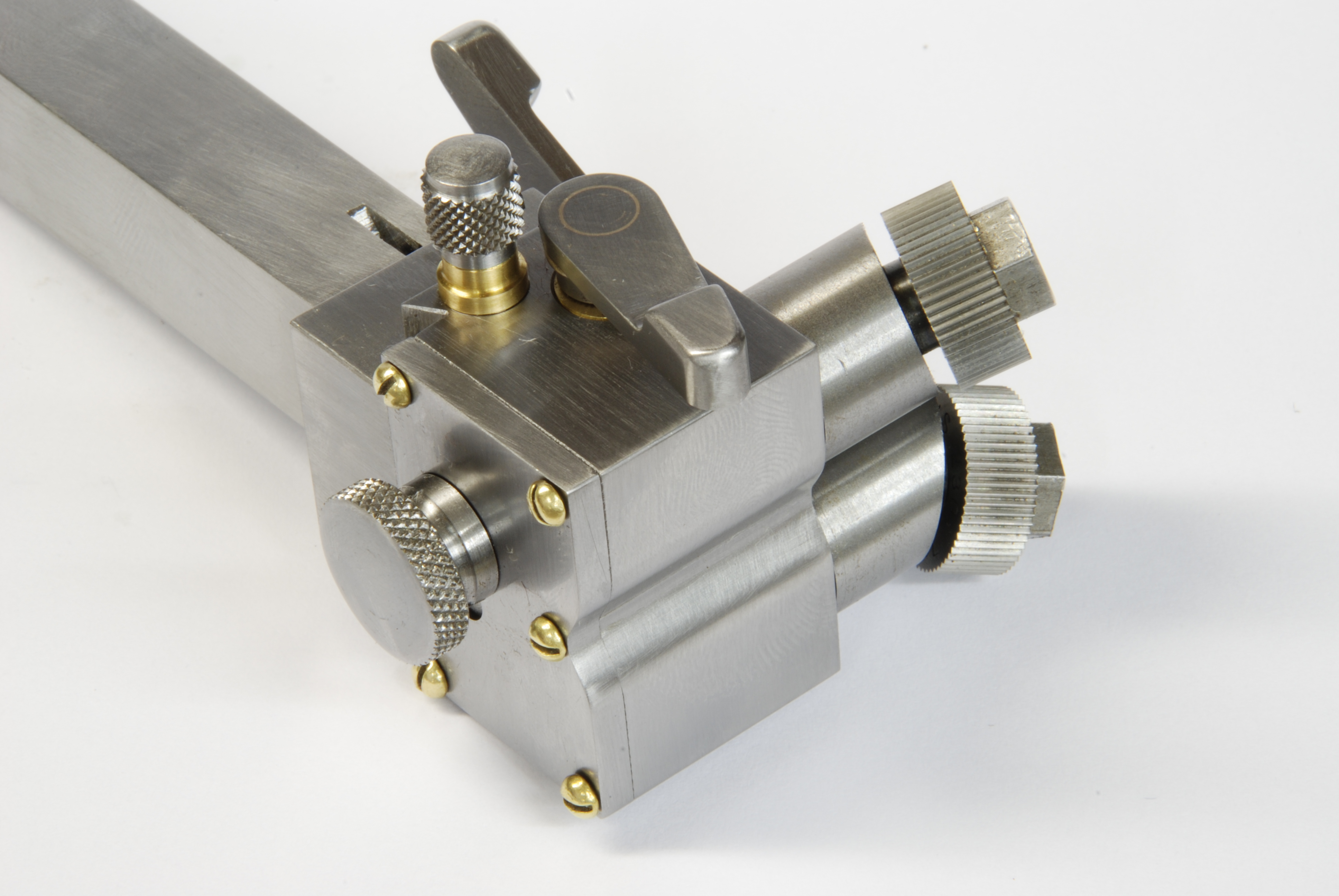

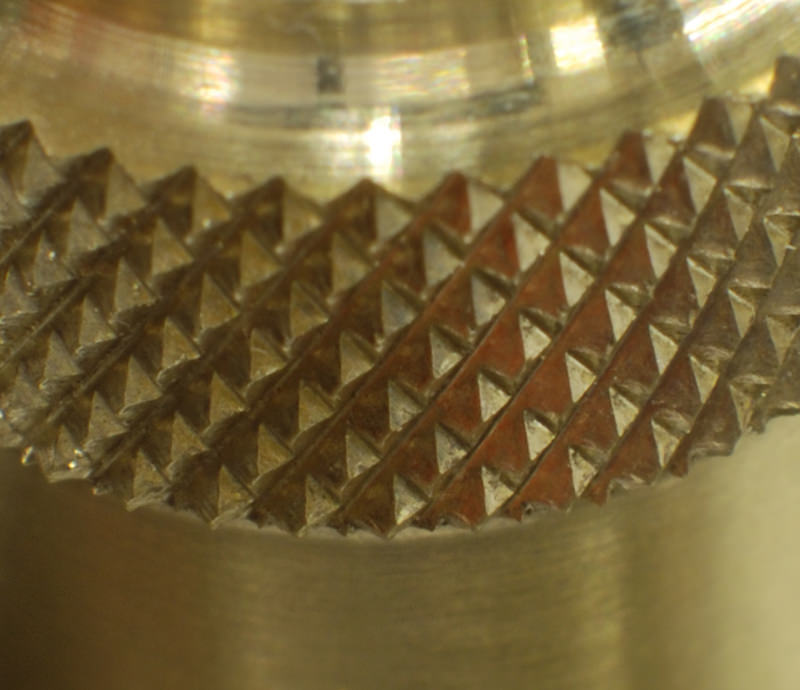

Aghast at the price, I designed and made one several years ago that ended up running as a build article in Home Shop Machinist. It started in March 2010, can't believe how time is racing by. Its a bit the deluxe model with gearing to adjust for different diameters, done via a knob on the left side second photo (its otherwise a pain the get them set right) and a fine height adjustment (otherwise a pain to get even knurls). Second photo is of a knurl it cut in brass; brass can be notoriously hard to get good knurls on because it work hardens and get crumbly...but it s a breeze with a cut knurling tool.

The scissor style work well. Crank it up, no undo pressure on any lathe parts and a full knurl in one pass.

Best are cut knurling tools. Run them at speed and get great knurls in a single pass.

Aghast at the price, I designed and made one several years ago that ended up running as a build article in Home Shop Machinist. It started in March 2010, can't believe how time is racing by. Its a bit the deluxe model with gearing to adjust for different diameters, done via a knob on the left side second photo (its otherwise a pain the get them set right) and a fine height adjustment (otherwise a pain to get even knurls). Second photo is of a knurl it cut in brass; brass can be notoriously hard to get good knurls on because it work hardens and get crumbly...but it s a breeze with a cut knurling tool.

Last edited:

Thanks....its a bit complex, but imo necessary to stop it being a complete pain to use as you need to make those adjustments each time you use it. A pic below of the simpler Mk I being used. The complexity came as a result of, sans those two adjustments, and me concluding "what a pita this is to use!". Pay me now or pay later sort of thing lol.

However don't let the complexity turn you away. While a complex project takes more time, there is no single set up, cut or op anyone wouldn't be able to do...and thats all any project is, a series of set ups and cuts.

The innards:

However don't let the complexity turn you away. While a complex project takes more time, there is no single set up, cut or op anyone wouldn't be able to do...and thats all any project is, a series of set ups and cuts.

The innards:

Last edited:

Former Member

Guest

Cut vs pressure, one of the ideal things with pressure knurling is it work hardens (forges) you knurling. In essence it leaves a case hardened finish increasing the life of the finished product.

In some materials this introduces other problems.

In some materials this introduces other problems.

eotrfish

Ultra Member

I made one a few years ago but dispensed with the height adjustment since the body was made to fit an AXA toolpost. I adjust height by turning the brass T-knob on top of the body.

It's an interesting project and as Mcgyver said so eloquently...

It's an interesting project and as Mcgyver said so eloquently...

there is no single set up, cut or op anyone wouldn't be able to do...and thats all any project is, a series of set ups and cuts.

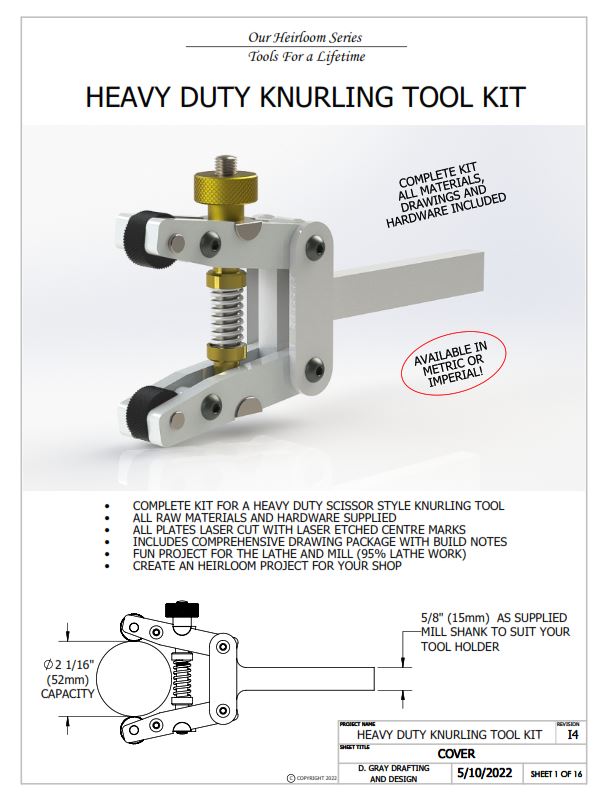

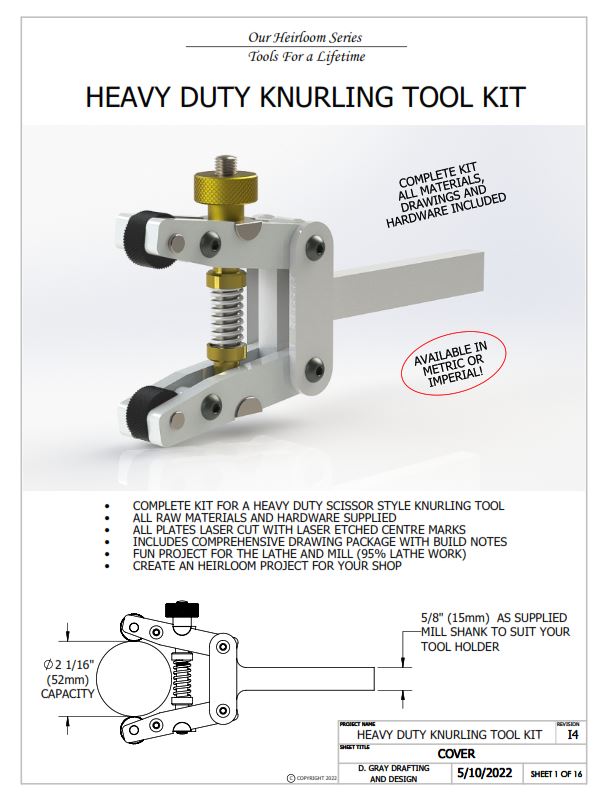

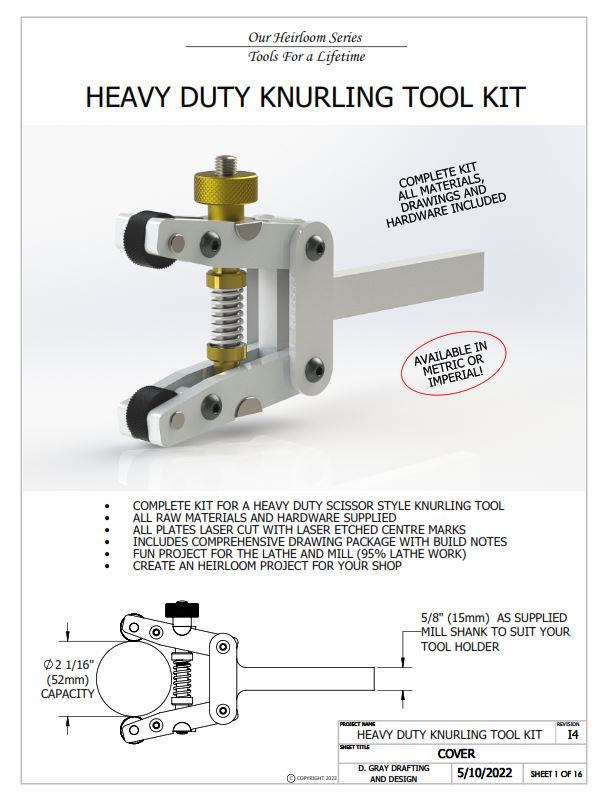

I just purchased a scissor type kit from Doug Gray Drafting and Design in Winnipeg.

The kit I got was the complete kit with all he required laser cut parts, a complete set of dimension and assembly drawings.

The literature is very well done and was easy to follow. I tried it out on various pieces of material and the results were better than I expected. I would highly recommend it.

I decided to go with the scissor style as the bump style I was using puts a massive amount of pressure on the spindle bearings, were as the scissor type does not. Here's the link to his site.

The kit I got was the complete kit with all he required laser cut parts, a complete set of dimension and assembly drawings.

The literature is very well done and was easy to follow. I tried it out on various pieces of material and the results were better than I expected. I would highly recommend it.

I decided to go with the scissor style as the bump style I was using puts a massive amount of pressure on the spindle bearings, were as the scissor type does not. Here's the link to his site.

Kits For The Home Shop Machinist/Tinkerer

Kits for the home shop machinist. Hi my name is Doug Gray thanks for stopping by my shop. I'm am the sole proprietor of D. Gray Drafting and Design. I lovingly create all the kits you see here in my shop. Everything from creating the drawing to assembling all the materials and packaging them up...

d-gray-drafting-and-design.myshopify.com

trlvn

Ultra Member

Doug Gray, a Canadian, has designed a knurler that might fit your needs:

Plans only are C$7. It is also available as a kit which includes all the materials, even HSS knurling wheels.

Craig

@Aliva hit "Post" just before I finished typing!

Heavy Duty Knurling Tool Drawings Only

Heavy Duty Knurling Tool Kit Drawings Only The drawings only version of this product is a pdf digital download of the complete 16 page drawing package that include building notes and full scale templates of the plates. An immediate digital download so no waiting or postage. Fantastic...

d-gray-drafting-and-design.myshopify.com

Plans only are C$7. It is also available as a kit which includes all the materials, even HSS knurling wheels.

Heavy Duty Knurling Tool Complete Kit

Heavy Duty Knurling Tool Complete Kit NOW SHIPPING!! Fantastic project for the lathe and mill (95% lathe work). Complete materials, hardware and drawings to create a valuable tool for your shop. Even the smallest of equipment can be used to produce this kit. This kit will provide several...

d-gray-drafting-and-design.myshopify.com

Craig

@Aliva hit "Post" just before I finished typing!

tourmax

Member

I use the pressure type without issues. The key is to have your QCTP locked down good and solid and make a couple passes to create the knurls. Has it's limitations, but has always worked fine for me.

My QCTP sits on a solid plinth, I ditched the top compound for regular use. I do everything on the plinth and only install the top compound when I need it for a specific task. I also milled two shoulders on the plinth to lock the QCTP in place. If anything turns, it is down at the angle adjustment on the saddle and if that turns, I know that I'm doing something very wrong....

My QCTP sits on a solid plinth, I ditched the top compound for regular use. I do everything on the plinth and only install the top compound when I need it for a specific task. I also milled two shoulders on the plinth to lock the QCTP in place. If anything turns, it is down at the angle adjustment on the saddle and if that turns, I know that I'm doing something very wrong....

I made one a few years ago but dispensed with the height adjustment since the body was made to fit an AXA toolpost. I adjust height by turning the brass T-knob on top of the body.p

It's an interesting project and as Mcgyver said so eloquently...

This is absolutely beautiful @eotrfish. I like the way I could adapt the geometry to fit my BXA Toolpost.

Do you have a drawing and a parts list?

You and @Mcgyver are two VERY Talented Machinists!

I just purchased a scissor type kit from Doug Gray Drafting and Design in Winnipeg.

The kit I got was the complete kit with all he required laser cut parts, a complete set of dimension and assembly drawings.

The literature is very well done and was easy to follow. I tried it out on various pieces of material and the results were better than I expected. I would highly recommend it.

I decided to go with the scissor style as the bump style I was using puts a massive amount of pressure on the spindle bearings, were as the scissor type does not. Here's the link to his site.

Kits For The Home Shop Machinist/Tinkerer

Kits for the home shop machinist. Hi my name is Doug Gray thanks for stopping by my shop. I'm am the sole proprietor of D. Gray Drafting and Design. I lovingly create all the kits you see here in my shop. Everything from creating the drawing to assembling all the materials and packaging them up...d-gray-drafting-and-design.myshopify.com

Boy, I'm tempted. Do the prices include shipping? How long did it take for the kit to arrive?

Six O Two

(Marco)

wow, some really amazing self-built knurling tools on display here!

In comparison, I feel like I hit the easy button on mine. I looked at the Doug Gray kits, but ended up just buying something off amazon. Having said that, these scissor-type ones have met my needs for the time being. Of course, when I bought them 2 years ago only, they were 2/3rds of the current price...

In comparison, I feel like I hit the easy button on mine. I looked at the Doug Gray kits, but ended up just buying something off amazon. Having said that, these scissor-type ones have met my needs for the time being. Of course, when I bought them 2 years ago only, they were 2/3rds of the current price...