V2 of the hardware has landed.

Well, at least the boards arrived at our Canadian "manufacturing facility" and have been assembled. So it is almost time for field testing with the v1 software.

View attachment 32567

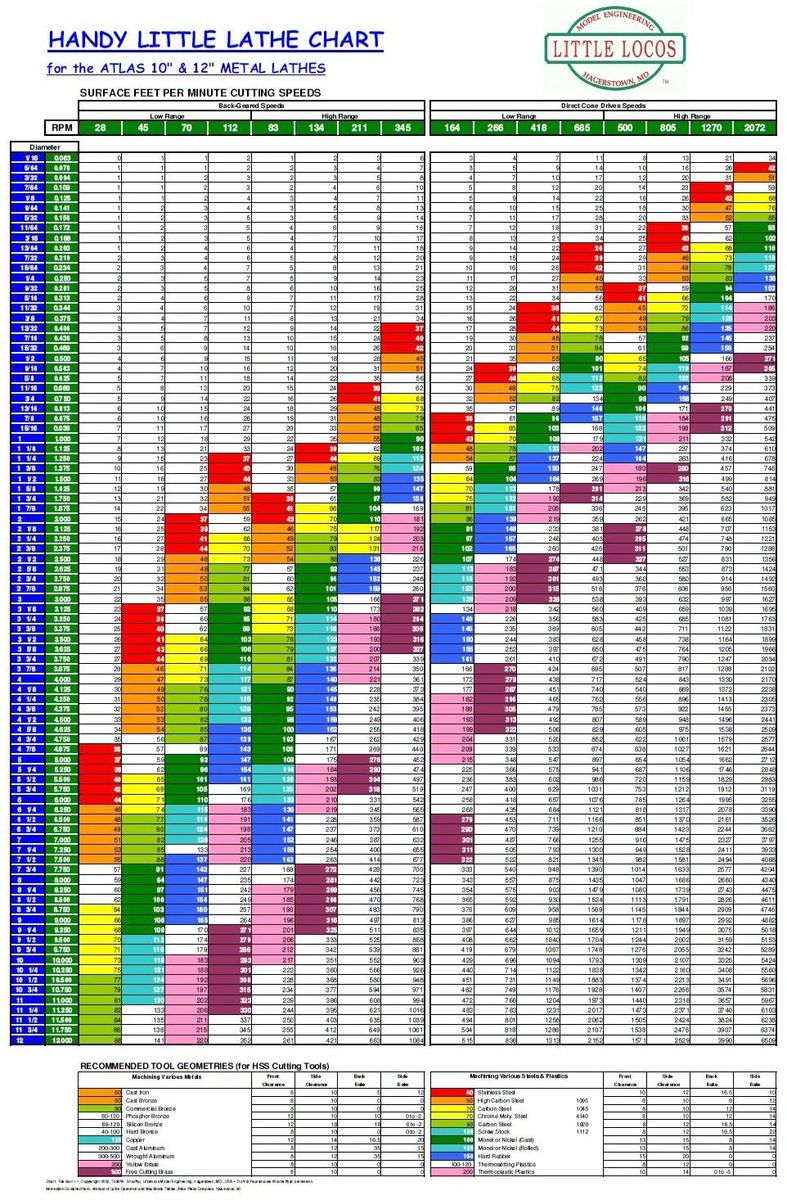

I'm still working, as my schedule allows, to compile data tables for the materials and cutter properties to be able to go live with V2 software.

I admit that I don't know enough to decide without consulting other more experienced machinists what materials I can/should omit from tables, or just lump into a group of similar materials. I know sites like the little machine shop have chosen to focus on very limited materials in their data tables because they know their user base only uses a handful of materials on a regular basis.

In just steel alone I have charts for 3 classes of non-alloyed steels, 1 low alloyed steels, 1 tool steel & high alloy steels, 5 classes of stainless steel and 6 classes of cast iron.

But I suspect I could omit all these non-alloyed steels with between 0.1-0.25% carbon. Raise your hand if you have ever used one of the steels in this example.

10PbF2

A27 65.35

A33

A34-2

A34-2NE

A515.65

A570.36

A573

A633

How about these non alloyed 0.26-0.50%carbon steels?

20AP

22CMSD4

3135

3415

35NCD14

A516

A516G60

A516G70

A537

A570

A572

A572.60

A70-2

A738

C25

1108

1112

1140

1144

1151

1213

1215

12L13

12L14