I think maybe you are over thinking this. M35 blanks from Amazon or Accusize or or or ..... will all work just fine once your tool geometry is right. The worst that will happen is the need to resharpen them more often. In 40 years I've never worn one out. I just keep resharpening them or grinding new profiles. I only just recently got into using inserts in any major way. Most of my original HSS didn't even have any cobalt in it at all.

Some time at the grinding wheel learning what works will pay bigger dividends than worrying about the kind of HSS you use.

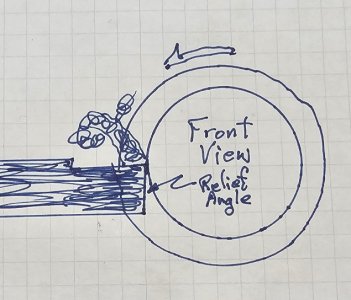

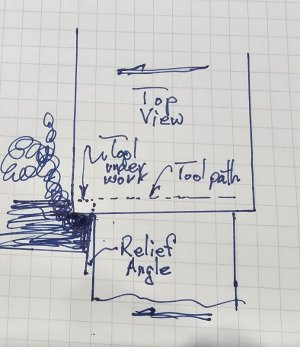

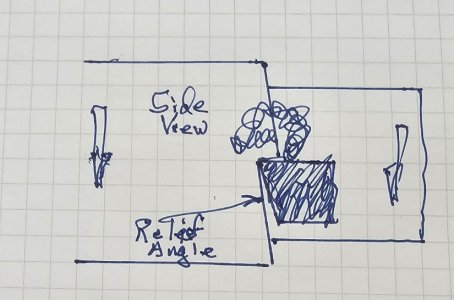

The biggest problem I see with new lathe operators is a fundamental misunderstanding of how the cutting process works. They assume that cutting takes place toward the lathe chuck. And some does. But very little. The vast majority of the cutting takes place around the circumference of the work - like peeling a spinning apple. It is the top of the tool that cuts, not the sides. The sides must all provide clearance so they don't rub - which is what your first experience was all about.

You will find a plethora of photographs and drawings on the Internet about how a tool cuts. Most of them are wrong. Here is a Sandvik photo of how the tool really cuts. It's not what you might think.

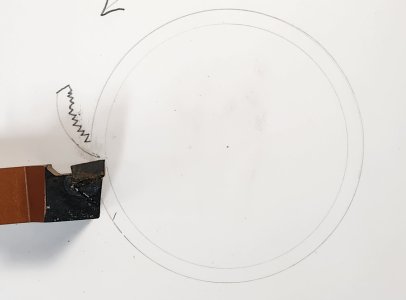

View attachment 42782

Notice that the work is rotating down (RED ARROW) against a more or less stationary tool. The tool isn't really cutting, it's actually more like plowing.

The tool does advance toward the headstock at the feed rate, but the majority of the force from the tool is PUSHING INWARD toward the center of the part which peels and buckles the chip off of the part, like peeling the Peel off of a spinning apple.

If you imagine the tool plowing along, you can immediately see the importance of relief on the faces of the tool that are adjacent to the part. You want the tool to cut (gouge) on the front and side top edge and buckle the work chip away from the parent part with the top of the tool. You don't want the tool to rub on the work at the front or the side.

This process is the same for carbide inserts or HSS.