Hi All,

I’m hoping you can help me with finding the right mill that suits my needs.

(Sorry for the wall of text but I want to provide as much info as I can so I can hopefully get some helpful advice.)

To start, I want to say that I have zero experience with machining, but I love to learn new skills and have wanted to dive into machining for quite a while now. I have decent CAD experience and have been 3d printing and building my own 3d printers for about 5 years now. I’ve been wood working and doing renovations for much longer, so I am decently knowledgable about mechanical things and working with my hands. I just don’t have any milling experience - though my Youtube history shows I must be an expert by now given how much machining youtube I watch 🙂

What am I planning to make with it?

I’m embarrassed to say this, but I’m not 100% sure. I really enjoy the journey of learning new skills, so for the next year or so it’s likely going to be tooling and jigs and so on as learn to get better.

But, longer term, I want to combine these skills with my other hobbies (wood working, software, electronics, CAD, 3d printing) to make pretty much anything I can think of. That’s what I love about all of these hobbies and how they play off each other, each new skill set is a new tool in my tool box to build things. And even though I could probably buy the thing for a fraction of the cost of building it, I love the satisfaction of knowing I built it. And sometimes, not being limited to only the things commercial available makes all the difference. I’m also an expert Yak Shaver, so any given project turns into 52 other side projects. So, I don’t tend to lack for projects.

Enough about me, here’s a list I created for myself to help narrow things down.

Wants:

Constraints:

Machines I’m considering:

I'm not allowed to post links yet so I've just given the model numbers, sorry.

BusyBee

Precision Mathews

I’m hoping you can help me with finding the right mill that suits my needs.

(Sorry for the wall of text but I want to provide as much info as I can so I can hopefully get some helpful advice.)

To start, I want to say that I have zero experience with machining, but I love to learn new skills and have wanted to dive into machining for quite a while now. I have decent CAD experience and have been 3d printing and building my own 3d printers for about 5 years now. I’ve been wood working and doing renovations for much longer, so I am decently knowledgable about mechanical things and working with my hands. I just don’t have any milling experience - though my Youtube history shows I must be an expert by now given how much machining youtube I watch 🙂

What am I planning to make with it?

I’m embarrassed to say this, but I’m not 100% sure. I really enjoy the journey of learning new skills, so for the next year or so it’s likely going to be tooling and jigs and so on as learn to get better.

But, longer term, I want to combine these skills with my other hobbies (wood working, software, electronics, CAD, 3d printing) to make pretty much anything I can think of. That’s what I love about all of these hobbies and how they play off each other, each new skill set is a new tool in my tool box to build things. And even though I could probably buy the thing for a fraction of the cost of building it, I love the satisfaction of knowing I built it. And sometimes, not being limited to only the things commercial available makes all the difference. I’m also an expert Yak Shaver, so any given project turns into 52 other side projects. So, I don’t tend to lack for projects.

Enough about me, here’s a list I created for myself to help narrow things down.

Wants:

- A NEW machine that ensures it’s only my own lack of skill that is the issue, and not the machine.

- I don’t want a used machine as I don’t feel I’m experienced enough to know when issues are caused by me vs the machine itself.

- A machine that is big enough that I don’t regret the purchase in a year once I gain some experience. But, not so big that I can’t fit it (see constraints).

- Materials I want to use include Steel, Brass, Aluminum, and other softer materials. While I don’t see myself doing much Stainless steel, it wouldn’t hurt if it could work with it.

- Most parts are likely to be on the small end, say under 6”x6” but I don’t want such a small machine that that is all I can manage. So, something in the range of a 28”-33” table would be ideal.

- From a cost perspective, I’d like to find a machine local to me (Burlington, Ontario), say within the GTA. But, I’m willing to spend the delivery cost if the machine is leaps above what is available locally (thinking Precision Mathews here).

Constraints:

- SIZE - I have roughly 70” W x 40” D x 96” H of room to allocate for the machine.

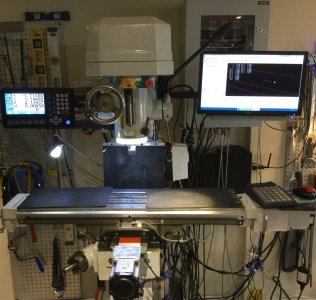

- my “shop” is a one car garage roughly 20’x10’ and it has all my wood working equipment, welding/welding table as well as a metal lathe (10x22 CX-706) I recent bought in it. So a large bench top model is likely my best bet.

- 120v/240v Single Phase Power - I do not have 3 phase. VFD is always an option I suppose.

- Budget - No specific budget but I’d like to keep it under $8/k CAD for the machine itself.

- I have a 2 ton engine hoist, but I would like to keep the weight under 500kgs or 1100lbs, for logistical reasons, though it’s not a hard limit.

Machines I’m considering:

I'm not allowed to post links yet so I've just given the model numbers, sorry.

BusyBee

- CX-601 - I’ve heard mixed things

- KC-45 - no experience with King

Precision Mathews

- PM-932M/V

- PM-833T/TV

- PM-728VT

- PM-30MV