ntdenman

Thomas

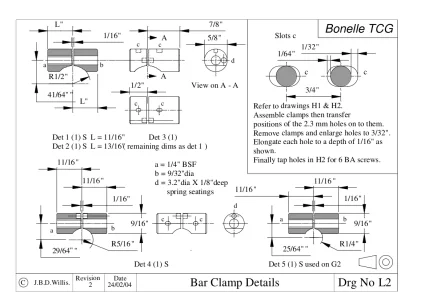

I'm interested in suggestions for setups to machine a tricky feature from the attached drawing; the parts are basically cylinders with a right-angle cylindrical 'bite' taken out of them at an offset location. I'd be making them out of brass rather than steel, which should help a bit.

It seems like it would be pretty straightforward to do the 'bite' in a mill, but I currently only have a small lathe. My first thoughts are:

- fix the cylinder with a sacrificial v-block in the 4-jaw, then drill and bore as if it was solid

- make an offset boring tool for the 4-jaw and then set the cylinder up on the cross slide (horizontal? vertical?), do an interrupted cut with the right radius and increasing depth

- set the cylinder up on the cross slide and then use a short line boring tool, otherwise same as above

Not sure what's likely to work, pretty sure it'll be slow going no matter what. I'd be interested to hear what you all think is a reasonable way of doing this. (I'm really hoping it's not 'buy a mill'.)

Cheers!

It seems like it would be pretty straightforward to do the 'bite' in a mill, but I currently only have a small lathe. My first thoughts are:

- fix the cylinder with a sacrificial v-block in the 4-jaw, then drill and bore as if it was solid

- make an offset boring tool for the 4-jaw and then set the cylinder up on the cross slide (horizontal? vertical?), do an interrupted cut with the right radius and increasing depth

- set the cylinder up on the cross slide and then use a short line boring tool, otherwise same as above

Not sure what's likely to work, pretty sure it'll be slow going no matter what. I'd be interested to hear what you all think is a reasonable way of doing this. (I'm really hoping it's not 'buy a mill'.)

Cheers!