Chris Cramer

Super User

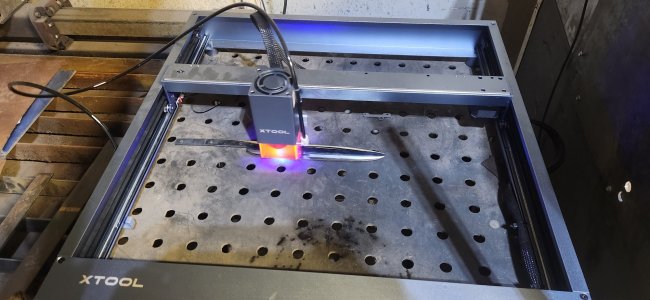

I Just purchased the new XTool D1 Pro 20W diode laser engraver. The tool works great for engraving, but I was a bit disappointed in the 20W module when it could not cut the 3/8" hard wood that I use for my knife handles. The 20W module does have enough power to engrave stainless steel which is the primary purpose I bought it for to add more creativity to my knife blades and maybe the handles. Xtool has released a 40W module which I'm thinking could cut harder wood and knife handle material. That would make work much more efficient; but the cost for that module is close to the price of the 20W D1 pro all together.