1018Machine

Super User

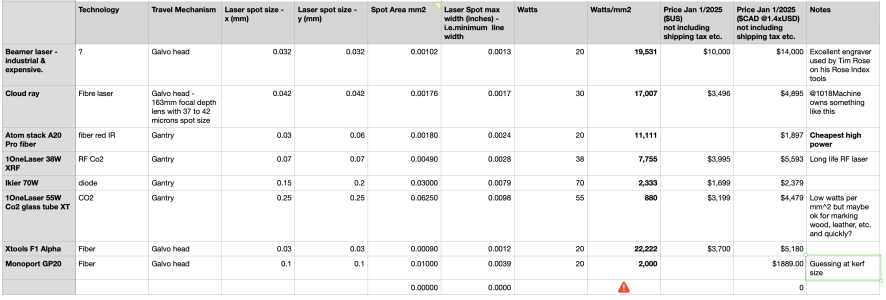

The horse is brass but only because it gives the best results for 2.5D engraving.The beam size and optical power I believe directly relates to the engraving and cutting capabilities although it is poorly stated everywhere. I believe this is similar to using a magnifying glass & the sun to burn wood. The tighter the focus the hotter the point of light, but it's smaller. So a 20W laser with a very small dot size could have dramatically higher power per square unit of area. And conversely a strong laser with a fuzzy dot could actually be slower and less capable. Although it depends on what you want - a big fat black line with the small laser dot size would take many more passes, the fuzzier dot would take fewer passes but with a slower travel time. There is a limit where a diffuse beam does not do anything - e.g. like how the magnifying glass with a 1/2" circle does nothing.

Trade offs as usual... But what laser strength do you need and what dot size to engrave metals, plastics, wood? Or maybe what can I get for $2000 to $3000? And do you mean "marking" or "engraving"? The horse above from @1018Machine is a great example of engraving. (What material is that horse @1018Machine ?)

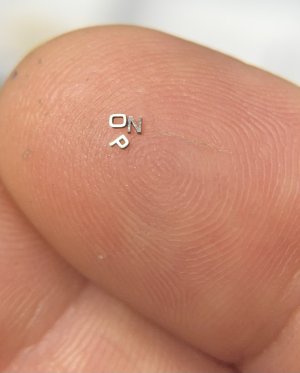

As for spot size it's reliant on the lens size. Obviously the larger the lens the larger the spot size. Detailed work is best one using a 70mm lens because the spot is very concentrated. You trade off work area but most fine work tends to be small.....like these letters I'm working on now.