1018Machine

Super User

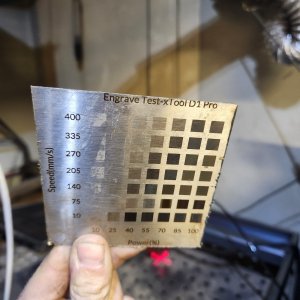

Yes, but you have to remember the cutting/engraving footprint is small, 5" dia max. with the lens I have. Materials such as stainless, O1, aluminum. brass.....basically any alloy. It's obviously not practical to use it to cut just anything but small complicated geometry, parts for my watching hobby and reel making hobby it's perfect. It shines when it comes to deep engraving mostly. Typically most of the stuff I cut is around .030" thick but I've cut as much as .100" at times, just takes longer. If you were to need it more for cutting you'd likely want something in the 100W range.You can cut metal with 30W? what kind of metal and how thick? how many passes? Please post some pictures of engraving and cutting.

Hers's some stuff I've done....

Hers' some .100" aluminum letters for a reel box (with a real 1/2 karat diamond)