I see them. Get a bigger phone LOLI don't have a left and right pic Peter.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

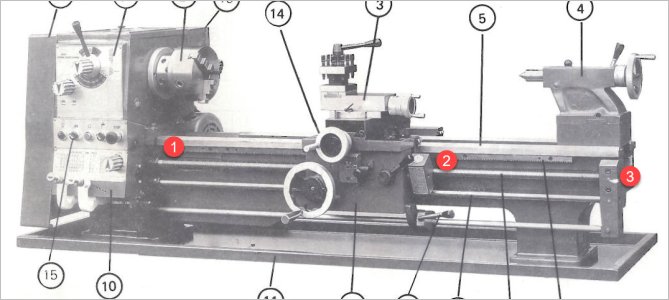

King 1440 and Craftex Threading

- Thread starter cuslog

- Start date

I see them. Get a bigger phone LOL

LOL! Not happening. Has to fit my pocket.

"I'm really only trying to help @cuslog fix his feed speed issue."

Thanks, but no point really -- I sold that lathe 3+ years ago and I owned it 15+ years and having done quite a bit of work on it, I'm pretty confident in the operation of it. That particular machine that I had, I could have power feeds OR I could cut threads if I opened up the end panel and changed a series of gears. The threading charts showed the gear change in the end panel. The power feed charts showed a different set of gears in the end panel.

Thanks, but no point really -- I sold that lathe 3+ years ago and I owned it 15+ years and having done quite a bit of work on it, I'm pretty confident in the operation of it. That particular machine that I had, I could have power feeds OR I could cut threads if I opened up the end panel and changed a series of gears. The threading charts showed the gear change in the end panel. The power feed charts showed a different set of gears in the end panel.

"I'm really only trying to help @cuslog fix his feed speed issue."

Thanks, but no point really -- I sold that lathe 3+ years ago and I owned it 15+ years and having done quite a bit of work on it, I'm pretty confident in the operation of it.

I see! Well that sure changes things then! LOL!.....

Dwelling on the past is generally a waste of time unless there is something to be learned.

That particular machine that I had, I could have power feeds OR I could cut threads if I opened up the end panel and changed a series of gears. The threading charts showed the gear change in the end panel. The power feed charts showed a different set of gears in the end panel.

Thats exactly how mine works too. But if I forget to invert the bushing on the mating gear, my threads will be ok, but my feed speeds don't match the chart. It's a tiny issue not covered in the manuals. I'd even go as far as to guess that many users have this problem and don't even know it.

I added the above strictly for the benefit of anyone else reading this thread in the future.

Yes that's what is in the Precision Matthews (PM1440HD) manual, the manual I got from Modern is pretty much useless. I haven't done all the math to determine what the unlisted gear combinations will do but one thing that annoys me is there is no 1.75mm thread listed for the GH lathe. I had to use a die to cut some M12 X 1.75 threads a few weeks ago.@John Conroy while we're on the subject, does this metric pitch availability look right to you - between your old (my current) 14x40 & your GH?

View attachment 32052

I don't have 1.75 either. I'm missing #N/A in the blue shade. I'm glad this came up in discussion. Changing gears may not be horrible but shifting levers or clicking knob detents is easier, that's for sure. I thought my banjo style gear box (or whatever you call it) was kind of outdated old school, but actually it offers quite a few in between sizes. But the Math Gods impose limits. I'm missing 0.4 & 0.7, common for M2 & M4 for example. Next lathe I would really examine this hard. Or just commit to ELS I guess. Not my forte is an understatement, but we have some members with experience or working on it.

1.75mm is .06895" so 1/.06895=14.503 TPI but my lathe can't do 14.5 TPI either. My lathe came with 25, 30, 32, 40, and 50 tooth change gears, Maybe some combination that's not listed would result in 14.5 TPI

Maybe a mechanical solution isn't so crazy after all, but depends how much the parts cost. Step 0) call Modern, order a metric feed screw & clamshell assembly. Then

1) make the headstock coupler universal so you can drop in IMP or MET feed screw. Mine has a crappy shear pin but that could be replicated or improved

2) swap out the IMP clamshell assembly with MET. Mine has a bolt to swing it back when not threading, but complete removal is actually easy. That solves the metric engagement issue

3) TS block would have to be modified. This requires thought. Ideally the feed screw would be disengaged & slip out to the right without block disassembly because it holds the other 2 shafts. Mine runs on a reduced diameter step segment within the block itself. I don't even think it has a bushing, just within a hole in CI block with oil lubrication. But maybe a bushing or bearing acting on thread OD? There is not a lot of radial force & the crests of ACME/trapezoid threads are flat of course.

I haven't though this through but I think you would get every metric pitch with the existing gears? Or would it also require gears we don't get on IMP machines?

ERROR ERROR ERROR. Duh! this is just the the indicator dial. The clamshell is of course up inside the apron. OK retrofit not practical after all

1) make the headstock coupler universal so you can drop in IMP or MET feed screw. Mine has a crappy shear pin but that could be replicated or improved

3) TS block would have to be modified. This requires thought. Ideally the feed screw would be disengaged & slip out to the right without block disassembly because it holds the other 2 shafts. Mine runs on a reduced diameter step segment within the block itself. I don't even think it has a bushing, just within a hole in CI block with oil lubrication. But maybe a bushing or bearing acting on thread OD? There is not a lot of radial force & the crests of ACME/trapezoid threads are flat of course.

I haven't though this through but I think you would get every metric pitch with the existing gears? Or would it also require gears we don't get on IMP machines?

ERROR ERROR ERROR. Duh! this is just the the indicator dial. The clamshell is of course up inside the apron. OK retrofit not practical after all

Attachments

DPittman

Ultra Member

I recently sold an older (1993?) 12x36 belt driven asian lathe that had the banjo style (I think they are also called Norton gearboxes?) and the only gear change outside of the gearbox was one gear to go from imperial to metric. All other thread combos were done with the gear box. I don't understand why they would not be able to keep that feature on every lathe. My little 10x22 lathe has knob selector gear box and the biggest range of threads I can get with any one gear combo change is three, everything else requires swapping out gears. I suspect there may be some other possibilities with my lathe but I have never been able to figure out the math to know for sure.I thought my banjo style gear box (or whatever you call it) was kind of outdated old school, but actually it offers quite a few in between sizes.

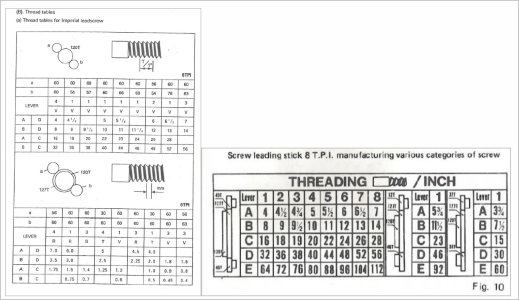

Here is my gear chart. It uses the same 120/127 gears as yours to switch between metric and imperial. But I seem to have larger change gears.

Talking only about metric for now, yours are 30, 32, & 40.

Mine are 30, 56, 60, & 63.

Note that to get 1.75 pitch, I need 60 & 56.

The top of this column is 7.0. So that is your target top gear. It will yield 7, 3.5, & 1.75.

Now, I have no idea what the internal ratios are. But all these lathes including mine are designed to cut each primary gear by exactly 1/2 internally.

Just stabbing in the dark, here.... 20 is to 40 is to 60 just like 14 is to 28 is to 56.

So, if you put 40 on your bottom gear and 28 or 29 on your top gear, I'm guessing that you will get your 1.75. You would just need to make a 28 or 29 tooth gear which is pretty darn close to your 30 so it should fit and should work at your C-B-3 selected position.

It would be good to set up a spread sheet with all the internal and external gears on it so this could be done more rigorously than my intuition though.

On the other hand, if you like making gears......

Also note the engagement of the B Gear on my 3 charts. My B gear can engage either the 127 or the 120 gear depending on which side of the gear has the bushing. But the only position corresponding to the feed chart is the 127 gear, not the 120. So it's easy for me to see why @cuslog's feeds may have been wrong on his old lathe.

Talking only about metric for now, yours are 30, 32, & 40.

Mine are 30, 56, 60, & 63.

Note that to get 1.75 pitch, I need 60 & 56.

The top of this column is 7.0. So that is your target top gear. It will yield 7, 3.5, & 1.75.

Now, I have no idea what the internal ratios are. But all these lathes including mine are designed to cut each primary gear by exactly 1/2 internally.

Just stabbing in the dark, here.... 20 is to 40 is to 60 just like 14 is to 28 is to 56.

So, if you put 40 on your bottom gear and 28 or 29 on your top gear, I'm guessing that you will get your 1.75. You would just need to make a 28 or 29 tooth gear which is pretty darn close to your 30 so it should fit and should work at your C-B-3 selected position.

It would be good to set up a spread sheet with all the internal and external gears on it so this could be done more rigorously than my intuition though.

On the other hand, if you like making gears......

Also note the engagement of the B Gear on my 3 charts. My B gear can engage either the 127 or the 120 gear depending on which side of the gear has the bushing. But the only position corresponding to the feed chart is the 127 gear, not the 120. So it's easy for me to see why @cuslog's feeds may have been wrong on his old lathe.

I've been doing some math (always dangerous for me) and came up with the following non standard gear arrangement that will get me 14.4tpi. 40 teeth on top and 32 on the bottom both meshed with the 127. Selectors set to B-C-2. I don't know if that's close enough to 14.5tpi to be workable but I'll try it to see how close it is to 1.75mm (it will actually be 1.7625mm thread pitch)

RobinHood

Ultra Member

It takes quite an elaborate Norton QCB to get 0.4, 0.7, 0.75, 1.75, etc of metric thread pitches. Not many manual lathes have them all.

I am lucky with the Colchester Master - it does have those pitches. Here is a picture of the (complicated) QCGB - if the Brits are good at something, it would be building good, compact manual gear boxes…

I am lucky with the Colchester Master - it does have those pitches. Here is a picture of the (complicated) QCGB - if the Brits are good at something, it would be building good, compact manual gear boxes…

Last edited:

I think you're right, if I had a 28 tooth gear I could get the M1.75 thread. This the entire threading chart.Here is my gear chart. It uses the same 120/127 gears as yours to switch between metric and imperial. But I seem to have larger change gears.

Talking only about metric for now, yours are 30, 32, & 40.

Mine are 30, 56, 60, & 63.

Note that to get 1.75 pitch, I need 60 & 56.

The top of this column is 7.0. So that is your target top gear. It will yield 7, 3.5, & 1.75.

Now, I have no idea what the internal ratios are. But all these lathes including mine are designed to cut each primary gear by exactly 1/2 internally.

Just stabbing in the dark, here.... 20 is to 40 is to 60 just like 14 is to 28 is to 56.

So, if you put 40 on your bottom gear and 28 or 29 on your top gear, I'm guessing that you will get your 1.75. You would just need to make a 28 or 29 tooth gear which is pretty darn close to your 30 so it should fit and should work at your C-B-3 selected position.

It would be good to set up a spread sheet with all the internal and external gears on it so this could be done more rigorously than my intuition though.

On the other hand, if you like making gears......

View attachment 32084

Also note the engagement of the B Gear on my 3 charts. My B gear can engage either the 127 or the 120 gear depending on which side of the gear has the bushing. But the only position corresponding to the feed chart is the 127 gear, not the 120. So it's easy for me to see why @cuslog's feeds may have been wrong on his old lathe.

Last edited:

I noticed that they never calculated a feed chart for the metric threading change gear combinations for any of the lathes.

The chart in the manual for my lathe doesn't include cross feed specs, only carriage feed. The placard on the front of the machine includes both and it similar to your lathe, there is about a 2.9-1 ratio between carriage feed and cross feed.

The chart in the manual for my lathe doesn't include cross feed specs, only carriage feed. The placard on the front of the machine includes both and it similar to your lathe, there is about a 2.9-1 ratio between carriage feed and cross feed.

Last edited:

I think you're right, if I had a 28 tooth gear I could get the M1.75 thread. This the entire threading chart.

Sometimes my brain works in ways that I don't even understand. It just sees stuff that I never consciously see. For some reason, i concluded that it might also be 29. Something about the internal/external tooth count. It works perfectly for fractional division but decimal is a compromise.

It is easy to see the internal divide by 2 structure (1, 1/2, 1/4, 1/8). But it's a bit cloudier to see the internal to external ratio.

It would be nice to do a full chart/equations in a spreadsheet to fully map it out. Then one could just calculate what is needed and/or see a list of outcomes for any set of gears.

I noticed that they never calculated a feed chart for the metric threading change gear combinations for any of the lathes.

Although this is obviously the case. I confess that I don't fully understand why.

At a minimum, I think they should state some thing about the faster feed rate ratio that will result from using the metric configuration. Or even just a warning. That would have prevented users like @cuslog from thinking the lathe was messed up and/or wasting a lot of time trying to fix it or understand it.

At a maximum, it would have allowed users to achieve another set of feed rates for those times when it might be needed.

Matt-Aburg

Ultra Member

Well, I have ran into an issue on my Craftex Lathe. I need to cut a 3/4 -10 thread for a spigot. I went to cut, put in proper position and it was cutting a fine thread. In my whole 15-20 years of owning that lathe I have never had to change gears. This poses a problem though. I found the gears below in a melted plastic box in the cabinets below. I also found the steady and follower rest and a bunch of other things. What a rats nest of sawdust on my old wood lathe. (that's all I ever used it for mainly)..

Here's the problem I am running into. The gears are stamped illegibly if at all. In the steel toolbox that came with the CNC Masters lathe, the gears are also illegibly stamped. At least I was able to confirm that the Craftex gears were for it because of the smaller bore size.

Short solution is to buy a 3/10 tap tomorrow at KBC and use the thread rod I bought at PA last week, with some red lock-tight. This will resolve my immediate problem. I found that rats nest and know where to go cleaning now. This lathe is going to get spotless. (as it was 20 yrs ago)..... Just a rant... I guess... I already had a backup plan....

Long term, maybe I wont' need to thread on this machine again. The CNC has an encoder.

GRRRRR

Upon re-examination, I can use the existing gear as is if I to a 3/4-16 thread. KBC has the nuts and stuff, so 89 cents beats 89 dollars any day !!! I still cannot believe how bad the stamping on those gears are...

Here's the problem I am running into. The gears are stamped illegibly if at all. In the steel toolbox that came with the CNC Masters lathe, the gears are also illegibly stamped. At least I was able to confirm that the Craftex gears were for it because of the smaller bore size.

Short solution is to buy a 3/10 tap tomorrow at KBC and use the thread rod I bought at PA last week, with some red lock-tight. This will resolve my immediate problem. I found that rats nest and know where to go cleaning now. This lathe is going to get spotless. (as it was 20 yrs ago)..... Just a rant... I guess... I already had a backup plan....

Long term, maybe I wont' need to thread on this machine again. The CNC has an encoder.

GRRRRR

Upon re-examination, I can use the existing gear as is if I to a 3/4-16 thread. KBC has the nuts and stuff, so 89 cents beats 89 dollars any day !!! I still cannot believe how bad the stamping on those gears are...

Last edited:

Correct. and the stuff I thread most (3/8-16, 5/16-18, 1/2-13) are all different gears.So If I want to to 20 TPI I engage C-4. But you have to mount gears 60-57 if you were in 60-60, that is not a lever select?