Hi All,

Maybe I complain too much but...

Here is something which looks so easy and straightforward on paper but when you get into it...

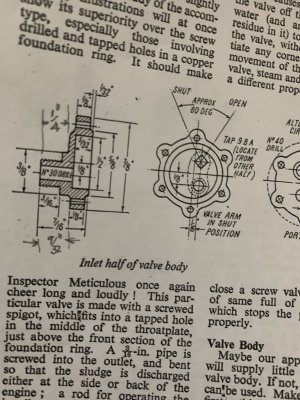

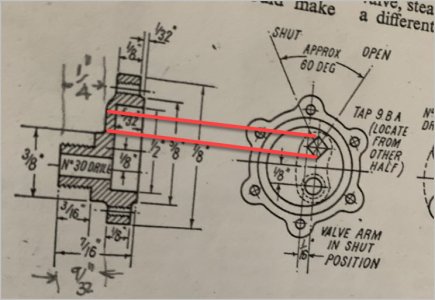

To set the scene. The drawing is of an "Everlasting" (Okadee type) live steam locomotive boiler blowdown valve (it happens to be in 3/4" scale) and the ones I am making are for a 1" scale locomotive so slightly larger.

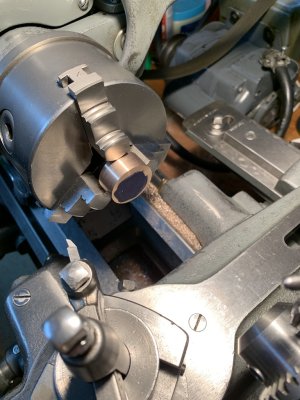

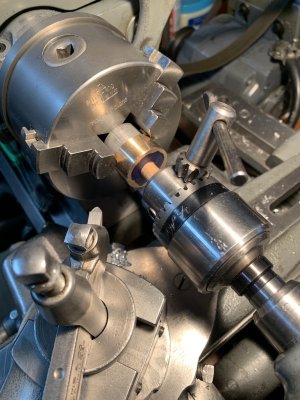

The first operation on the bronze blanks are to machine the 1/2" OD by 5/32" deep inner pocket. The constructor (LBSC) says one can use a 1/2" D-bit or one bore it out as an alternative.

OK, but there are two things here; one is the bottom corner of the pocket has to be a sharp 90 degree corner and the other is the inner recess surface has to be truly flat (from the corner to the centre) as it acts as a flat surface against which a valve (face) operates and it has to be steam tight.

OK, I got it in the end but it was anything but straightforward.

to be continued.

Maybe I complain too much but...

Here is something which looks so easy and straightforward on paper but when you get into it...

To set the scene. The drawing is of an "Everlasting" (Okadee type) live steam locomotive boiler blowdown valve (it happens to be in 3/4" scale) and the ones I am making are for a 1" scale locomotive so slightly larger.

The first operation on the bronze blanks are to machine the 1/2" OD by 5/32" deep inner pocket. The constructor (LBSC) says one can use a 1/2" D-bit or one bore it out as an alternative.

OK, but there are two things here; one is the bottom corner of the pocket has to be a sharp 90 degree corner and the other is the inner recess surface has to be truly flat (from the corner to the centre) as it acts as a flat surface against which a valve (face) operates and it has to be steam tight.

OK, I got it in the end but it was anything but straightforward.

to be continued.