I'm at my kitchen table instead of at my lathe. I just want to cut the 1/2"-13 thread for a lead screw to hold my MT3-ER32 collet adapter. I tried with a die, but there's more tool pressure than I or my 3-jaw can hold. So I thought I'd single point it. I've done it before, it should be easy.

Except for this horrific contraption to set lead screw speeds:

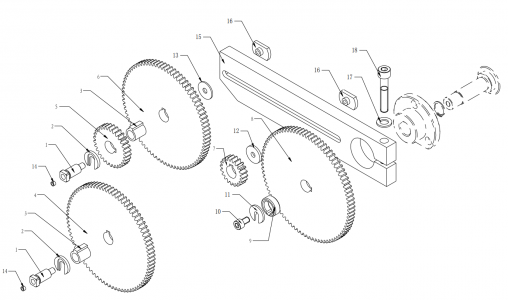

Most of it seems quite harmless. It's covered in black mess, and the gears need their axle-holes reamed out before they fit on the shafts. I can almost live with that. There's even a safety interlock on the cover to keep my fingers out of the meat grinder. But clip "2" in the diagram is completely lost on me - I can't get the little buggers to stay on while allowing part "3" to rotate on the shaft - tighten down the nut on "1" enough to hold them and the shaft seizes up, don't do so and hear the clip get flung off after a minute or two.

The clip is recessed on the front to accept the nut. On the back (not seen in the diagram) there's a proud section that seats into the gear (or the spacer...don't get me started about the spacers "9").

Anyone have advice on how to deal with the clips? I've resorted to shims between the gears to take up slack, and though fussy it seems to help.

Mind you, today, after two failed attempts to cut these threads (spoiling the part the second time) from throwing the clips off halfway through the operation, I'm very much thinking of binning the whole lot and installing an electronic lead screw. Advice welcome in this direction as well.

Except for this horrific contraption to set lead screw speeds:

Most of it seems quite harmless. It's covered in black mess, and the gears need their axle-holes reamed out before they fit on the shafts. I can almost live with that. There's even a safety interlock on the cover to keep my fingers out of the meat grinder. But clip "2" in the diagram is completely lost on me - I can't get the little buggers to stay on while allowing part "3" to rotate on the shaft - tighten down the nut on "1" enough to hold them and the shaft seizes up, don't do so and hear the clip get flung off after a minute or two.

The clip is recessed on the front to accept the nut. On the back (not seen in the diagram) there's a proud section that seats into the gear (or the spacer...don't get me started about the spacers "9").

Anyone have advice on how to deal with the clips? I've resorted to shims between the gears to take up slack, and though fussy it seems to help.

Mind you, today, after two failed attempts to cut these threads (spoiling the part the second time) from throwing the clips off halfway through the operation, I'm very much thinking of binning the whole lot and installing an electronic lead screw. Advice welcome in this direction as well.