-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips/Techniques HOUSE OF TOOLS LD 1236G

- Thread starter MooseMeat

- Start date

Tips/Techniques

Q. is there a cutter shape guide chart on what the different cutters are used for, there are over 500 cutters of different shapes, sizes, profiles, and colours, I don't know where to start, google I guess....

Doesn't look like anyone answered your question. I'm fairly new at using and understanding inserts too. I used HSS most of my life and I'm mid 70s, so a very long time.

I have found that the guys on here are generally more help to me than any reference. However, I did find one book in particular to be quite good at putting everything together in one place. I recommend getting a copy of "Introduction to indexable Tooling for the Metal Lathe" by David Best. It's fairly recent and did wonders for my background knowledge base.

The nomenclature for ANSI & Imperial is also confusing. It is worth taking some time to understand the difference because you will encounter both.

I don't see any toolholders in your haul. If you have any, you should drag those out and see what they are. Maybe post a picture with the model number showing. That will help you get a handle on your baseline and help us help you.

It would also be helpful to do an inventory of your inserts, make a list, and post that too. I don't think you really have "all of them" - it just looks like you do. Most likely you really have an assortment that covers a range of uses for his tool holders.

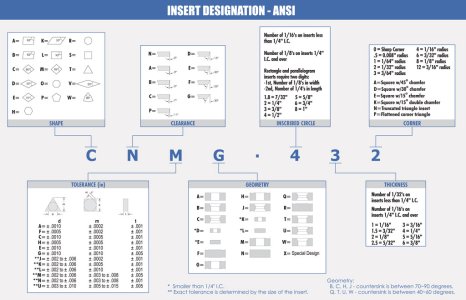

Inserts are designated by size, shape, nose radius, target material, coating, etc. Here is a sample chart. There are similar charts from most of the different insert manufactures.

I only chose the one on Little Machine Shop because it's generic.

As a newbie insert user, I can tell you that you will get lots of advise about what to use for what. Turns out that is mostly what others use for what and the stuff is actually more versatile than is usually discussed.

I personally like the Trigon shape because of its versatility and its strength. One right hand tool holder will both face and turn. A left hand holder will add facing and turn from the left too. But you will probably also need a profiling tool, a parting tool, and threading tools.

Let's start with what you have. I certainly wouldn't recommend buying anything else right now.

Edit - I see @combustable herbage posted similar stuff while I was writing.

historicalarms

Ultra Member

Welcome from Central Ab. and i will add suggestion to the above post before you go thru the gyrations of leveling the machine , if you have the floor space available, also move the lathe out from the wall so you have access for repairs, belt tightening, general cleaning and the odd time taking measurements from the back is easier( it happens).Looking good! my only suggestion would be too move the lathe out from the wall on the tailstock end to allow easier install/remove of the tailstock .

Welcome from Central Ab. and i will add suggestion to the above post before you go thru the gyrations of leveling the machine , if you have the floor space available, also move the lathe out from the wall so you have access for repairs, belt tightening, general cleaning and the odd time taking measurements from the back is easier( it happens).

I second this. I have access on all three sides and an opening on a structural storage rack on the left to allow access through the rack for longer shafts through the headstock. Cannot underestimate the convenience of access to the rear and sides of a lathe. Locate for access, then align. Multiple alignments are a royal PIA.

@combustable herbage @historicalarms On this lathe it isn't necessary for the lathe to have room in the back. Removing the tailstock, adjusting belts and all maintenance can be done from the front and above.

Clearance through the headstock is very helpful - I have had up to 4' pipes through mine and it performs very well!

----

The place to begin with inserts: that is going to involve checking what you have. Look for a holder and inserts that have *positive rake* This machine is beefier than a SB 9a, but still suffers from flex under pressure. One of the possibilities you have so much variety is that some of the insert geometries work 'less well' on your lathe, so they kept hunting for ones that worked better....

I started with positive rake TCMT 332 inserts on mine: that is a triangle geometry insert, with a 7 degree relief built in, so the insert fits flat on the holder, with a simple chip breaker. this insert from flat to flat to flat inscribes about a 3/8" circle

Another tip to begin with, just to prevent extra things to diagnose: when you have chosen your tool holder, buy some inserts ground for turning aluminum. Sounds stupid, right? buying inserts when you have hundreds! But hear me out. These inserts cut steel, even tool steel with far less pressure and leave a better finish than regular inserts. They don't wear as long in steel as inserts made for steel, but still wear better than HSS tooling in most cases. You can get started with turning that way and get great results out of the gate.

When you have a couple of pounds of shavings on the floor, begin to experiment with the inserts you have, doing the work you intend. There are a million little pointers to know about turning, especially in softer materials - like aluminum or brass, but you wanted a starting point.

Clearance through the headstock is very helpful - I have had up to 4' pipes through mine and it performs very well!

----

The place to begin with inserts: that is going to involve checking what you have. Look for a holder and inserts that have *positive rake* This machine is beefier than a SB 9a, but still suffers from flex under pressure. One of the possibilities you have so much variety is that some of the insert geometries work 'less well' on your lathe, so they kept hunting for ones that worked better....

I started with positive rake TCMT 332 inserts on mine: that is a triangle geometry insert, with a 7 degree relief built in, so the insert fits flat on the holder, with a simple chip breaker. this insert from flat to flat to flat inscribes about a 3/8" circle

Another tip to begin with, just to prevent extra things to diagnose: when you have chosen your tool holder, buy some inserts ground for turning aluminum. Sounds stupid, right? buying inserts when you have hundreds! But hear me out. These inserts cut steel, even tool steel with far less pressure and leave a better finish than regular inserts. They don't wear as long in steel as inserts made for steel, but still wear better than HSS tooling in most cases. You can get started with turning that way and get great results out of the gate.

When you have a couple of pounds of shavings on the floor, begin to experiment with the inserts you have, doing the work you intend. There are a million little pointers to know about turning, especially in softer materials - like aluminum or brass, but you wanted a starting point.

MooseMeat

Active Member

yes pretty overwhelming and very thankfulLooks awesome man. You lucky dog, I'd be feeling like a spoiled kid on Christmas morning.

MooseMeat

Active Member

,Super, thank you@combustable herbage @historicalarms On this lathe it isn't necessary for the lathe to have room in the back. Removing the tailstock, adjusting belts and all maintenance can be done from the front and above.

Clearance through the headstock is very helpful - I have had up to 4' pipes through mine and it performs very well!

----

The place to begin with inserts: that is going to involve checking what you have. Look for a holder and inserts that have *positive rake* This machine is beefier than a SB 9a, but still suffers from flex under pressure. One of the possibilities you have so much variety is that some of the insert geometries work 'less well' on your lathe, so they kept hunting for ones that worked better....

I started with positive rake TCMT 332 inserts on mine: that is a triangle geometry insert, with a 7 degree relief built in, so the insert fits flat on the holder, with a simple chip breaker. this insert from flat to flat to flat inscribes about a 3/8" circle

Another tip to begin with, just to prevent extra things to diagnose: when you have chosen your tool holder, buy some inserts ground for turning aluminum. Sounds stupid, right? buying inserts when you have hundreds! But hear me out. These inserts cut steel, even tool steel with far less pressure and leave a better finish than regular inserts. They don't wear as long in steel as inserts made for steel, but still wear better than HSS tooling in most cases. You can get started with turning that way and get great results out of the gate.

When you have a couple of pounds of shavings on the floor, begin to experiment with the inserts you have, doing the work you intend. There are a million little pointers to know about turning, especially in softer materials - like aluminum or brass, but you wanted a starting point.

MooseMeat

Active Member

On itLooking good! my only suggestion would be too move the lathe out from the wall on the tailstock end to allow easier install/remove of the tailstock .

As far as inserts maybe post a picture of the lathe tools you have maybe give a better idea of what will be most commonly used but this is a start the tool is sometimes task specific but the inserts' can be the same or different.

A QCTP maybe something you want to look at if you get tired of swapping in tools into the 4 way post.

Lathe Cutting Tools - A Guide to Lathe machine Tools with PDF

Lathe cutting tools are used to perform different operations in lathe. The tools are Turning tool, Chamfering tool, Boring tool, thread cutting tool etc.www.theengineerspost.com

MooseMeat

Active Member

No I don't have a mill, I've ran outa room in my little shop, I'd have to "fire" a couple of tool boxes to fit one in, and I don't even want to think about getting a mill to the back yard, this thing almost killed me as it is.Very nice...... Do you have a milling machine as well? I see you got a lot of end mills in the batch. If you don't, a milling attachment for your lathe, and a little bit of patience and you can do a lot with a little....

Of course, most of us will point out that since you already have a bunch of mill tooling..........

MooseMeat

Active Member

Thank you for the chart and advice, cheersDoesn't look like anyone answered your question. I'm fairly new at using and understanding inserts too. I used HSS most of my life and I'm mid 70s, so a very long time.

I have found that the guys on here are generally more help to me than any reference. However, I did find one book in particular to be quite good at putting everything together in one place. I recommend getting a copy of "Introduction to indexable Tooling for the Metal Lathe" by David Best. It's fairly recent and did wonders for my background knowledge base.

The nomenclature for ANSI & Imperial is also confusing. It is worth taking some time to understand the difference because you will encounter both.

I don't see any toolholders in your haul. If you have any, you should drag those out and see what they are. Maybe post a picture with the model number showing. That will help you get a handle on your baseline and help us help you.

It would also be helpful to do an inventory of your inserts, make a list, and post that too. I don't think you really have "all of them" - it just looks like you do. Most likely you really have an assortment that covers a range of uses for his tool holders.

Inserts are designated by size, shape, nose radius, target material, coating, etc. Here is a sample chart. There are similar charts from most of the different insert manufactures.

View attachment 44398

I only chose the one on Little Machine Shop because it's generic.

As a newbie insert user, I can tell you that you will get lots of advise about what to use for what. Turns out that is mostly what others use for what and the stuff is actually more versatile than is usually discussed.

I personally like the Trigon shape because of its versatility and its strength. One right hand tool holder will both face and turn. A left hand holder will add facing and turn from the left too. But you will probably also need a profiling tool, a parting tool, and threading tools.

Let's start with what you have. I certainly wouldn't recommend buying anything else right now.

Edit - I see @combustable herbage posted similar stuff while I was writing.

MooseMeat

Active Member

The lathe is all wired up and I have been running through the controls and have noticed a "quirk." The red stop push pull button won't cut the power of immediately, sometimes the power shuts off in a few seconds and other times it takes 30 seconds or so. I have cleaned the contacts and blew them out with air but the issue persists.

Any thoughts??

cheers and thanks.

Any thoughts??

cheers and thanks.

That’s definitely odd as mine shuts off the power instantly.The lathe is all wired up and I have been running through the controls and have noticed a "quirk." The red stop push pull button won't cut the power of immediately, sometimes the power shuts off in a few seconds and other times it takes 30 seconds or so. I have cleaned the contacts and blew them out with air but the issue persists.

Any thoughts??

cheers and thanks.

MooseMeat

Active Member

I think I found it,That’s definitely odd as mine shuts off the power instantly.

the reverse contactor pops right away, the forward contactor however likes to stick, in the on position, you can push in on the contactor button and it works fine, in and out no hesitation or stickiness, operate it from the controls is a different story.

MooseMeat

Active Member

Yes she's a beauty, still had hardended factory grease in the cross side feeds, pulled them apart and cleaned them up, the machine is very tight, everything seem to slide like glass.The machine looks like you just took the wrapping off, very nice.

You could also try unplugging the power and just cycle the switch on/off a bunch of times and see if that helps. If it's been sitting for a while it may just need some exercise.

You could be right, it has been sitting for a few years I think, and the fella I bought it off of only made a few parts on it.

You could be right, it has been sitting for a few years I think, and the fella I bought it off of only made a few parts on it.

I think my biggest concern there is that you said it pops right away when operated manually. This makes me think the control voltage is drifting for a while. It wouldn't hurt to put a meter or a scope on the control voltage to see if the control voltage is drifting or the contactor is sticking from lack of use.

MooseMeat

Active Member

when operated in reverse it turns off immediately, I'm no electrician, I'm learning as I go, however I do have family close by who are electricians, I should lean on them instead of me fumbling around, but hey, I have no issue sticking a multi meter on anything.I think my biggest concern there is that you said it pops right away when operated manually. This makes me think the control voltage is drifting for a while. It wouldn't hurt to put a meter or a scope on the control voltage to see if the control voltage is drifting or the contactor is sticking from lack of use.

Mine is the Busy Bee version of the same lathe, and was doing the same thing. Had to change the contactor. a local electrician had one that worked but it is slightly larger than the original so now the panel door will not close all the way. Seems these contactors are a common item. One other item about these lathes: mine had a motor shield to protect the motor from splash. Well, turned out that the shield would interfere with the carriage if it got too close to the headstock. Cost me a halfnut and a shaft as well as time tearing the thing apart. Tossed the shield. Check yours.

when operated in reverse it turns off immediately,

Another sign the control voltage is drifting. All you want to do is discover whether the issue is mechanical or electrical. If the control voltage changes right away but the contactor hangs in there, it's mechanical. If the control voltage decays over time or is delayed, it's electrical.

MooseMeat

Active Member

Thank you, I'll look into these possibilities, this is going to be a good learning experience, I'm quite anal about things working properly but lack the skill.Mine is the Busy Bee version of the same lathe, and was doing the same thing. Had to change the contactor. a local electrician had one that worked but it is slightly larger than the original so now the panel door will not close all the way. Seems these contactors are a common item.