Mcgyver...... you said you’ve done so. Do you do them professionally?

I'm very much the amateur! lol I've built my shop up by doing a lot of buying and selling. It became almost sport. Anyway, the result is seeing a lot of indicators, and a lot that needed help. With an interest in watchmaking, I gives me the key tools so I started having a go at it. Dones lots of indicators., DTI's, bore gauges, indicating mics...common themes start to develop. I by no means would go toe to toe with a pro, but compared to a watch they are quite simple and so far I've been able to figure it out.

There's four reasons they don't work (that I've seen)....based on my (small) sample group this is the approx. distribution.

1) grunge/oil - 92%

2) cracked jewel - 4%

3) damage from a drop (i.e. bent teeth on a rack) 3%

4) just plain old worn out 1%

1) is an easy fix, clean like you would a watch (L&R multi stage cleaning/rinsing). 2) is more of a challenge, at least economically. The jewels are many times larger than those used for watches so hard to source and seem to be $20 or so. Its often more than one that is broken so by the time you do the exchange, add in shipping etc buying the jewels (synthetic ruby, zero gem value) it usually exceeds the value of the used indicator. You could replace the jewels with bronze, but what imo is a better idea is small ball bearings. (I was doing one of these this morning and will put pics of ball bearing conversion below ) 3) & 4 are also almost always toss-worthy, not worth the cost of the parts.

I also feel its rare that they are worth sending anywhere for repair. In TO you can almost always find a Mitutoyo for 80 -$100 and an Interapid for 150 - 200....hard to mail it somewhere, have a technician service it and get it back for less than that.

Oil. In my opinion indicators should NOT be oiled. I've not found any authoritative decree on this either way, but with some watch making knowledge/experience my logic is as follows. Oiling a watch is a demanding thing - it has to be done just so or it doesn't work. Its one the things that is easily screwed up. The reason is, the geometry of the jewel is such that surface tension will hold just the right about of oil in place. Put too much on, and the surface tension can't hold, and it all runs off. We are talking a very small amount - you need to work with a loupe to apply it. This would not work on an indicator as the jewels are huge - the surface tension isn't going to be able to hold that much oil in place.

Next point, compare the duty cycle of a watch to a indicator. 5:000:1 10,000: 1 50,000:1? many watches run for a very lone time with lubricant, I don't think an indicator needs the watch does given comparatively minuscule duty cycle

Finally, every mechanical watch should be serviced (completely disassembled, cleaned and re oiled) every 3-5 years. Despite being watertight, dust and crap somehow gets in and oils dry out. That's what's needed if lubrication is used (and the duty cycle of watch dictates it must). In fact, if you don't, get in a clean, remove grunge and paste like dried oil, you might argue your watch would be better if run dry. When was the last time anyone took an indicator in for cleaning and oiling.... and on a regular basis? But you would have to if it was lubricated and you expected it to perform for a long time.

Just some random indicator thoughts....here's some shots of a ball bearing conversion...I'm going way off topic, but how much more can flog the auctioneer?(yeah, and it still wouldn't be enough! lol

a cracked jewel

size comparison - cracked jewel, watch sized jewel (and a largish one at that) and a 3mm x 1mm ball bearing. the exacto blade is just for scale

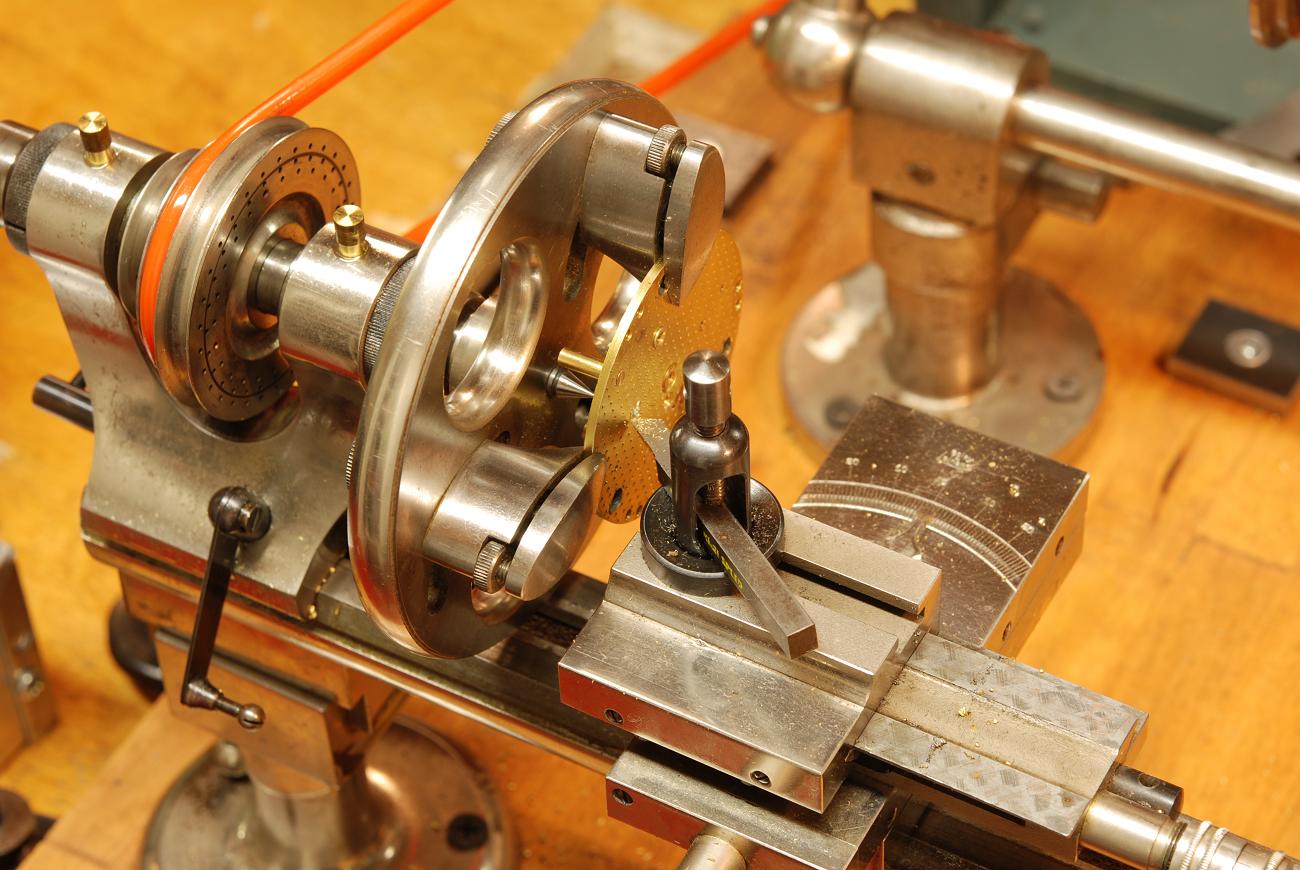

making a bunch of 'chatons', the brass holders for the bearing that get pressed into the plate

when you get a turret set up working....make a lot of them!

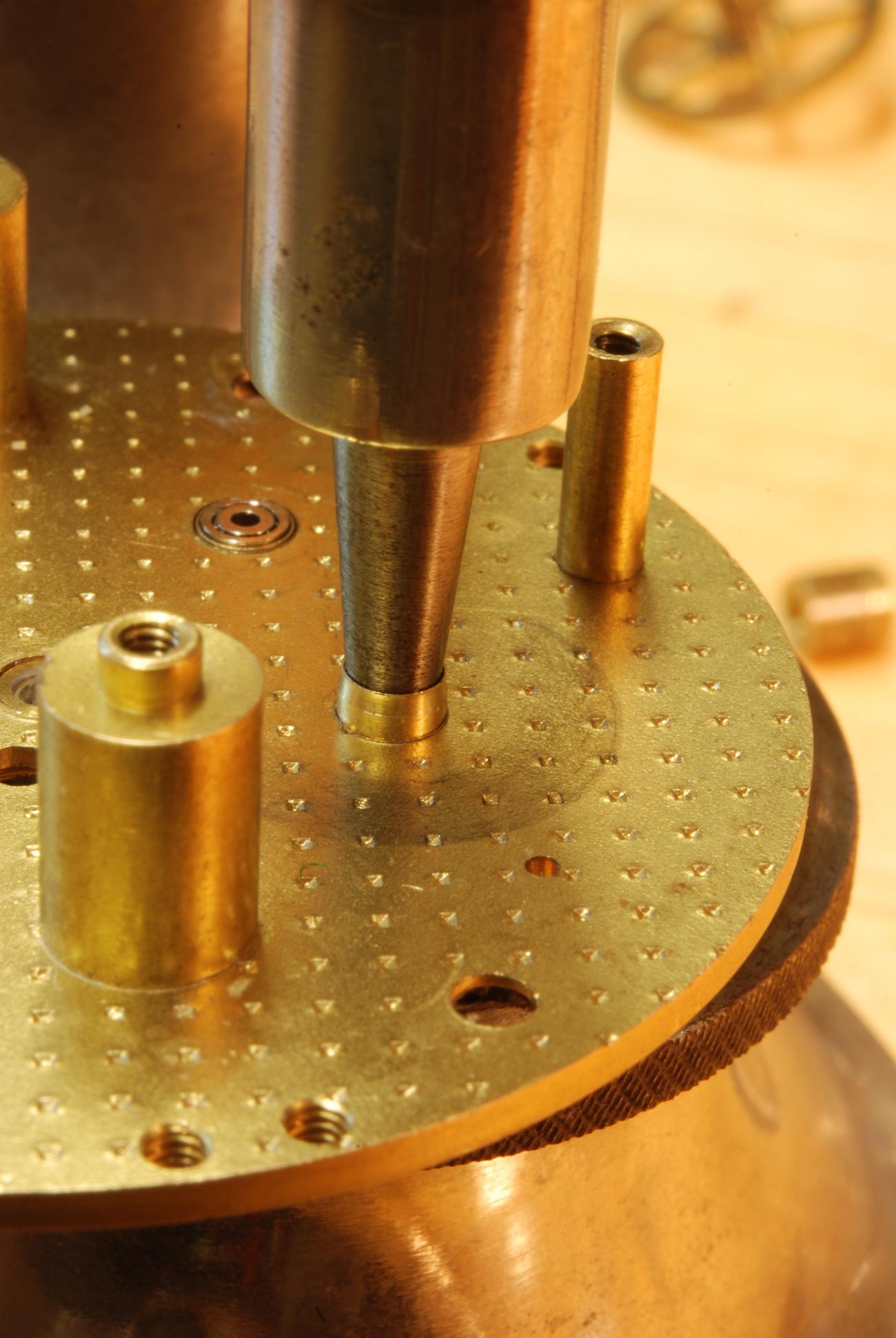

pressing the bearing and chaton in

facing it flush - a bit of rodico is stuffed in the bearing to keep chips out of it

bearing installed and new life for the indicator