I'll use the new plate that

@Darren made, which is a copy of the plate on my lathe.

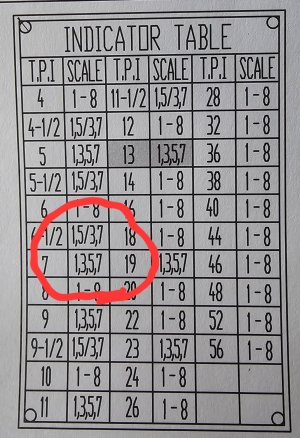

It says that if I need to cut a thread with 1/4 tpi, I need to close the half-nuts at the same numbered line. So if I need to cut a 5 3/4 tpi thread (which my lathe is capable of doing, I have to close the half-nuts at either 1 or 2 or 3 or 4.

Ok, sure if I use a 5 3/4 tpi thread for the Cone of Silence, it will come off and go on very quickly, but the depth of that thread is 0.094" that's way too deep for our purpose.

Lets say for now we want to cut 5 3/4 tpi. We set our QCGB to 5 3/4, and we start our threading at #1 on the thread chasing dial. We do that first pass, disengage our half-nuts, go back to the beginning, and wait until the #1 comes around again (because, remember to cut a 1/4 thread we have to close the half-nuts at the same number always), and when it does we engage.

Now if we close our half nuts at the #1, make a cut, and the next pass we close the half nuts at the #3 (which is the number directly opposite #1 on the thread chasing dial), we will have made a cut in between the previous thread. So now we have two threads being formed, so now we have 2 x 5 3/4 tpi threads, which is 11.5 tpi. The depth of cut for 11.5 tpi is 0.047". So if we close our half-nuts alternating between the #1 and the #3 on the chasing dial, and cut to a depth of thread of 0.047", we have a perfect 2-start thread.

But that was still too deep.

So lets keep our QCGB set to 5 3/4 tpi but this time we close our half nuts at the 1 and 2 and 3 and 4 marks on the chasing dial. We have now made 4 x 5 3/4 tpi thread = 23tpi. A 23 tpi thread has a depth of cut of 0.024". So now we have a 4-start thread with 23 tpi. And at 0.024' depth of thread, that works perfectly for my purpose.

I have even made an 8 start thread, by using the lines in between the numbers of the chasing dial. (just as an experiment)

The only issue when cutting multi-start threads is that you must have enough clearance on your threading tool so that it doesn't rub on the tread due to the greater helix angle. For carbide inserts you can get angled shims which sit below the threading insert. For HSS you have to grind the relief.

Does this work with every lathe? I really don't know. But my lathe has a lead screw of 4tpi, I can only hypothesize that any other lathe with the same lead screw pitch will work similarly, but you have to try it out.

This is absolutely the fastest, easiest method of cutting multi-start (at least 2-start and 4-start).

But, my lathe only has 4 different pitches with 1/4 threads (2 1/4, 2 3/4, 3 1/4, 5 3/4 tpi), so I am limited at the pitches I can cut. If I was asked to do a 3-start, then I have to use a different method.