-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Half-Nut Engagement

- Thread starter thestelster

- Start date

RobinHood

Ultra Member

I don’t think you wasted anyone’s time! Certainly not mine.Yup, I wasted everyones time. My sincerest apologies. I thought, incorrectly, that the bottom steel half-nut meshed with the bronze worm gear. When in fact, behind the worm gear is the upper portion of the half-nut, d'oh!! The bronze piece is just there for the ride.

Had to think about your question and look / figure out how this actually worked.

On all three of my lathes, the actual dial face (green arrow) is rotationally adjustable on the dial stem (red arrow) to make the dial face lines line up exactly with the reference mark (blue arrow). The picture below shows the Colchester Master 2500 dial.On my South Bend, the lines don't quite line up when I engage the half nuts, but trail just a little bit behind.

Perhaps your Southbend has some sort of adjustment as well to make the marks line up better?

Is this scenario plausible?

Just to be clear to others reading this.

No, it's not plausible. Which slot of the thread dial gets used or how much it wears has nothing to do with when the half nut is engaged. The half nut always only engages on a set of sections on the lead screw and since the lead screw only rotates, the half nut always follows the identical path on the lead screw no matter what pitch is chosen. The only thing that the pitch selection does is change the ratio between the lead screw and spindle rotation. The lead screw and half nut travel are always the same no matter what. They never change.

140mower

Don

Not wasted time when someone learns something, or even just clears up the muddy water a little.Yup, I wasted everyones time. My sincerest apologies. I thought, incorrectly, that the bottom steel half-nut meshed with the bronze worm gear. When in fact, behind the worm gear is the upper portion of the half-nut, d'oh!! The bronze piece is just there for the ride.

historicalarms

Ultra Member

Im late to this party but my 2 cents worth;

any lead screw wear difference will be so small & insignificant in the distance traveled for one revolution of the thread dial.

I have an old Atlas lathe in my shop that has noticeable lead screw wear and the old fellow that owned it before he passed was a demon at cutting threads on that machine. I have been involved in helping him & his son change a bushel of rifle barrels threaded on his very wore lathe. He could cut threads that perfectly matched every brand of action his son came up with that required a barrel change.

His son & I have discussed trying to find a new lead screw for that old lathe but the comment made in this thread about being able to swap end and use a new side has me wondering now....domething to look at in the spring when the shop thaws.

any lead screw wear difference will be so small & insignificant in the distance traveled for one revolution of the thread dial.

I have an old Atlas lathe in my shop that has noticeable lead screw wear and the old fellow that owned it before he passed was a demon at cutting threads on that machine. I have been involved in helping him & his son change a bushel of rifle barrels threaded on his very wore lathe. He could cut threads that perfectly matched every brand of action his son came up with that required a barrel change.

His son & I have discussed trying to find a new lead screw for that old lathe but the comment made in this thread about being able to swap end and use a new side has me wondering now....domething to look at in the spring when the shop thaws.

I don’t think you wasted anyone’s time! Certainly not mine.

Had to think about your question and look / figure out how this actually worked.

That's how I feel too. I got one of the best nights sleep I've had in ages out of it and it cleared up a question I have pondered myself since I got my first lathe 50 years ago.

I am grateful to @thestelster for the opportunity to put my mind to an open question and clarify my thinking on it.

There is only a tiny shadow of doubt about the impact of poorly machined change gears. But even that is just a micron on a table ruler.

140mower

Don

It might, but I think I sold this lathe, minus the threading dial, so I might try and change it when I put the next lathe into service. Honestly though, it doesn't bother me at all, I hit the lever on the line and just past it, the nuts fall into place.Perhaps your Southbend has some sort of adjustment as well to make the marks line up better?

Its not a waste of time question because it brings clarity to how threading occurs. Yes, the clamshell / threading rod is what dictates the carriage being moved along, now synchronized to HS rotation which translates into a particular pitch. The indexing wheel is a necessary visual aid to indicate when the clamshells can/should be engaged.

Sometimes you will hear someone say 'I engage not on the line but a certain amount before or after the actual line' & engagement works much better. That's fine but there is more to the story & does not constitute advice. On some lathes the indicator wheel itself can be adjusted & it may have slipped over time. Or if non-adjustable, was installed & pinned incorrectly at factory (more common than you think). In other words the clamshell engagement is perfectly fine, but the ' engage signal' is messed up. Do this enough times & the clamshell wears unnecessarily. There is also reaction time issue. Some people start the engagement a line width before the actual matchup because it takes a split second for brain to hand to lever to engagement. There is a bit of fudging & latitude depending on the lathe & RPM & other factors. I try not to force mine, certainly don't slam it, firm but feel it, if that makes sense, eventually you know what your lathe likes.

Thread variations can come about with wear or alignment issues in the thread screw and/or clamshells. Usually the brass/bronze clamshells wear sacrificially vs steel screw but are replaceable. Typically they are retained by dowel pins & screws so if they loosen over time, that alters the fit to the screw. Its possible the lead screw shear pins / hole is becoming loose & starting to float under load. Or it could be re-installed 180-deg out of phase which can put the dial markings slightly out of phase. But its probably not 180-deg if it was hand drilled like my lathe :/

Sometimes you will hear someone say 'I engage not on the line but a certain amount before or after the actual line' & engagement works much better. That's fine but there is more to the story & does not constitute advice. On some lathes the indicator wheel itself can be adjusted & it may have slipped over time. Or if non-adjustable, was installed & pinned incorrectly at factory (more common than you think). In other words the clamshell engagement is perfectly fine, but the ' engage signal' is messed up. Do this enough times & the clamshell wears unnecessarily. There is also reaction time issue. Some people start the engagement a line width before the actual matchup because it takes a split second for brain to hand to lever to engagement. There is a bit of fudging & latitude depending on the lathe & RPM & other factors. I try not to force mine, certainly don't slam it, firm but feel it, if that makes sense, eventually you know what your lathe likes.

Thread variations can come about with wear or alignment issues in the thread screw and/or clamshells. Usually the brass/bronze clamshells wear sacrificially vs steel screw but are replaceable. Typically they are retained by dowel pins & screws so if they loosen over time, that alters the fit to the screw. Its possible the lead screw shear pins / hole is becoming loose & starting to float under load. Or it could be re-installed 180-deg out of phase which can put the dial markings slightly out of phase. But its probably not 180-deg if it was hand drilled like my lathe :/

That is why on some Standard Modern lathes (SM1340, for example) the lead screw is reversible. Just take it out, turn it around and now you have a “brand new“ lead screw - well, at least an unused section - good for another 50 years.

Thank you @RobinHoo. I'd never have known about this if you hadn't mentioned it. But it turns out mine is the same. It looks like it's a piece of cake to reverse it. There is a shear pin at both ends and the unthreaded shaft is the same diameter. Might need a different drilling for the shear pin but it looks and rough measures the same.

Not that I'll ever care in my lifetime cuz I'll never wear out the current end with the years I have left. But maybe one of my great great grandkids will care in their lifetime if my lathe should be so lucky as to stay in the family that long.

In investigating the reversible lead screw that @RobinHood mentioned, I made another discovery. I've actually read about it elsewhere but I don't recall it being discussed here.

Apparently there are two indexes where the half nut will close between each of the existing 8 marks on my thread dial. A total of 24 possible indexes. The tweeners are not marked, but they are there. My lead screw is 8tpi.

There is probably some simple math formula that relates the target thread pitch to which one of the index marks works out, but I don't know what it is. I only know that any mark (including the hidden ones) will work for 8, 16, 24, 36, etc because any one of them aligns exactly on any given 1/2 nut engagement. Basically, for any of those I think you can just engage the 1/2 nut at will and ignore the setting on the thread dial completely.

Apparently there are two indexes where the half nut will close between each of the existing 8 marks on my thread dial. A total of 24 possible indexes. The tweeners are not marked, but they are there. My lead screw is 8tpi.

There is probably some simple math formula that relates the target thread pitch to which one of the index marks works out, but I don't know what it is. I only know that any mark (including the hidden ones) will work for 8, 16, 24, 36, etc because any one of them aligns exactly on any given 1/2 nut engagement. Basically, for any of those I think you can just engage the 1/2 nut at will and ignore the setting on the thread dial completely.

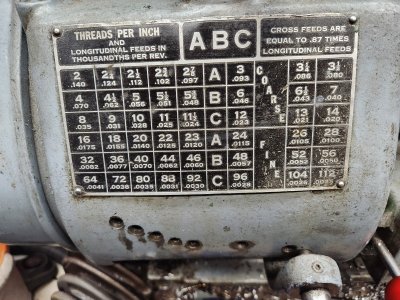

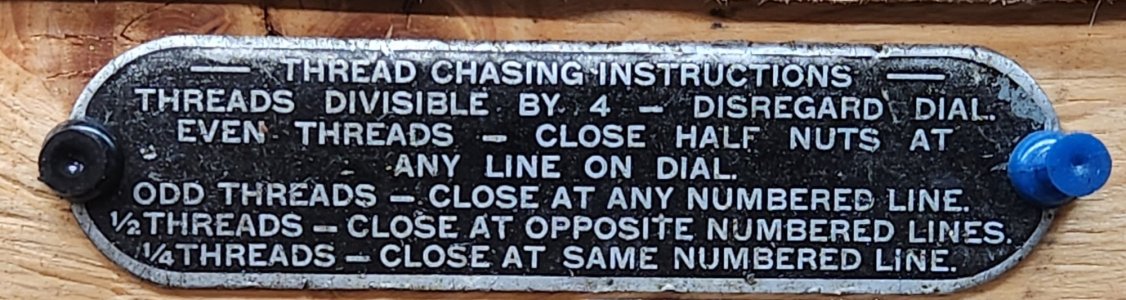

My lead screw is 4tpi. I have 4 numbered marks, and in-between marks. But I can close the half nuts in between those as well, for a total of 16 engagement positions. And when cutting any thread divisible by 4, I can disregard the dial, and close at any of those 16 engagement positions.In investigating the reversible lead screw that @RobinHood mentioned, I made another discovery. I've actually read about it elsewhere but I don't recall it being discussed here.

Apparently there are two indexes where the half nut will close between each of the existing 8 marks on my thread dial. A total of 24 possible indexes. The tweeners are not marked, but they are there. My lead screw is 8tpi.

There is probably some simple math formula that relates the target thread pitch to which one of the index marks works out, but I don't know what it is. I only know that any mark (including the hidden ones) will work for 8, 16, 24, 36, etc because any one of them aligns exactly on any given 1/2 nut engagement. Basically, for any of those I think you can just engage the 1/2 nut at will and ignore the setting on the thread dial completely.

My lead screw is 4tpi. I have 4 numbered marks, and in-between marks. But I can close the half nuts in between those as well, for a total of 16 engagement positions. And when cutting any thread divisible by 4, I can disregard the dial, and close at any of those 16 engagement positions.

Wow, 4tpi eh! What diameter?

I think my biggest surprise was the double tweeners. I would not have been surprised with just one. It just seems so odd to make it every third tooth when it all works on an even numbered 8tpi lead screw. Even as I write this I am questioning myself. It should have been 16 or 32, not 24. I already triple checked it cuz I was so surprised. I'll prolly check it again today.

There is a mystery there that needs to be solved.

Also, I have an outstanding todo for another member regarding threading options. It's cold out and high time I did some book research on how this all works.

1.250"Wow, 4tpi eh! What diameter?

Johnwa

Ultra Member

It is pretty simple but also easy to forget. The threads you mention all have a complete number of threads every ⅛”. Therefore you can close on any threads on the leadscrew. Even numbers of tpi have complete threads every 1/2”. Corresponding to 4 threads on the leadscrew. My thread dial has a 32 tooth gear so I can close on the 1/8th marks (4 leadscrew threads). Odd numbers of threads have a complete number every 1” so I can close on the ¼ marks (8 leadscrew threads). Usually though I just use the same mark for all threads. It’s slow if you’re doing fine threads at low rpm though.There is probably some simple math formula that relates the target thread pitch to which one of the index marks works out, but I don't know what it is. I only know that any mark (including the hidden ones) will work for 8, 16, 24, 36, etc because any one of them aligns exactly on any given 1/2 nut engagement. Basically, for any of those I think you can just engage the 1/2 nut at will and ignore the setting on the thread dial completely.

RobinHood

Ultra Member

I think you are correct: using another mark on the dial will not necessarily give you a multi start thread - at least not predictably.

What should give you a multi start thread though is if you advance (or retard) the drive gear on your spindle wrt the driven gear in your gear train by 1/2 turn - for a two start thread (or 1/4 turn, 4 times, for a 4 start) thread, etc.

I have to check that on my lathes to see if that works correctly because if I have an odd number of teeth on the spindle gear, it won’t work for an even number of thread starts. (i can’t recall how many teeth are on the spindle drive gear of each lathe.)

I know on some Hendey lathes that is how they do it. Steve Summers shows it in this video at ~3:35 mark.

What should give you a multi start thread though is if you advance (or retard) the drive gear on your spindle wrt the driven gear in your gear train by 1/2 turn - for a two start thread (or 1/4 turn, 4 times, for a 4 start) thread, etc.

I have to check that on my lathes to see if that works correctly because if I have an odd number of teeth on the spindle gear, it won’t work for an even number of thread starts. (i can’t recall how many teeth are on the spindle drive gear of each lathe.)

I know on some Hendey lathes that is how they do it. Steve Summers shows it in this video at ~3:35 mark.

Nope. Lots of time spent understanding how my lead screw actually works. That's totally not a waste.Yup, I wasted everyones time.

Actually, I've done it before. For a 4-start thread. On my lathe any 1/4 thread, you must engage the half nuts at the same number on the thread chasing dial.Just out of curiosity could using different marks be used for multi thread I don’t think so but had to ask I’m of the camp that uses the same mark every time.

So for instance, if I select a 5 3/4 thread on my QCGB, since I have to engage at the same number: 4 (4-start) x 5 3/4tpi = 23tpi. So calculate what the depth of cut is for a 23tpi and cut to the depth engaging at each of the numbered lines.

Easy peasy, and perfect. The only thing you have to worry about us your flank clearance.

Attachments

Just out of curiosity could using different marks be used for multi thread I don’t think so but had to ask I’m of the camp that uses the same mark every time.

Personally, I would go with a plunge cut instead of 29.5, and then use the compound to advance half a thread for two. Or 1/3 for three.

It's that or some testing before cutting. One thing is for sure, the thread dial method won't work for multiples of your lead screw pitch.

I also like @RobinHood's idea of moving the gears on the spindle, but that's a bit tricky and if you lose your place..... Wooo Hooo!

I spent some time in the shop today and confirmed everything we talked about up to this point.

I am totally done worrying about using other marks on the thread dial. No more waiting for the dial to come around for me. I just can't understand why I've taken so long to do this. Old habits don't die easy I guess.

I am totally done worrying about using other marks on the thread dial. No more waiting for the dial to come around for me. I just can't understand why I've taken so long to do this. Old habits don't die easy I guess.