What makes it a bit more challenging at least with online calculators & formulas is the logical assumption you are cutting metric threads with a trapezoidal tool or ACME threads with an ACME tool. They can spit out PD using wires or whatever as long as you stay within the corresponding system. I could be way off base here, but if they are cutting inch pitch with trapezoidal tool to serve N-Am market so the dials correspond to typical 0.100" per rotation, it would be an odd duck, but would work perfectly fine. Seems illogical to do it this way, but so are many similar things on these machines. Anyways, I'm pretty sure I can just lay out the shaft OD & appropriate thread form in CAD, do a path guided cut along a pitch equivalent helix & it will yield a section view I can pick off any dimension to confirm. I can confirm external thread parameters this way.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CA-BC Grizzly order - anyone on South Island need anything?

- Thread starter curmudgeon

- Start date

British Columbia

- Type

- Tool

curmudgeon

(Steve)

Yup, the PO let his inner gorilla out to play. One could accomplish the same thing with a set screw setup like yours if motivated.Maybe the screw was advanced too far & it cracked.

The compound has to be removed to access the cap screw and set screw on mine.

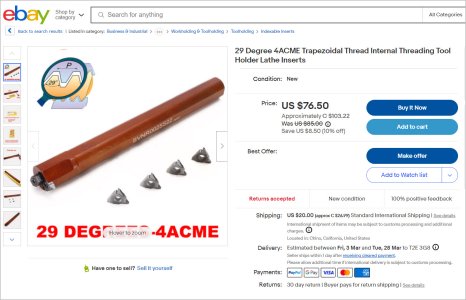

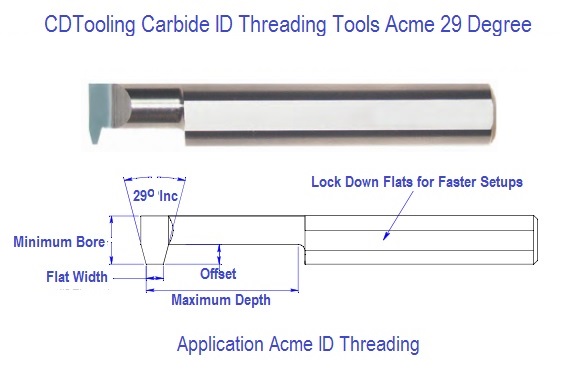

I found a source for ACME internal threading tools. They come in a range of max depth so for a typical nut width about $90. Not much different cost than the special tap so choose your poison. An insert is probably cheaper but you need appropriate holder. Trapezoidal are cheap but doesn't do you much good restoring a N-Am machine.

Carbide ID Acme Threading Tool 29 Degree - Min. Bore .200 - Max Depth .400 - ID: 2312-32-1200

www.carbideanddiamondtooling.com

curmudgeon

(Steve)

for sure, I could drop it off when I'm out next monthIll take a milling machine, One of those bridgeport clones.

You take EMT?

Thanks!

curmudgeon

(Steve)

no argument from meIMHO, flexing cast iron to take out backlash is a flake move. Fine if it was bronze.

hmmm, why not? I have an idea in mind that I'll share in a new, project thread.I think that nut is ripe to be replaced with a better design.

In any event, that thin section is gunna break in cast iron but I'd wager it would break even in bronze - hence my thought to break it properly and design with that.

hmmm, maybe not - with some design help, I can do betterSo the question becomes, do you want another of the same? As in new replacement.

There is a ball oiler located directly above the lead screw; squirt and hope that some lands on the lead screwSpeaking of which, how is the nut lubricated?

Sometimes the goldie bronze color can be deceptive if its cast surface or covered in wear sludge or painted at the same time which they are fond of doing.

Definitely not bronze.I had wondered the same thing. Old bronze could easily look like cast iron. The break would be a good place to look.

Threads are LH TR10x1.5mm - this tap looks very affordable - https://www.ebay.com/itm/254605460804What size tap do you need? I have 1/2-10LH and 3/8-10RH acme taps. All you need is a chunk of bronze and a to drill a hole.

Could you reslit the the nut to make it useable until a replacement is ready?

There's enough material left to slit the opposite end and drill/tap a new mounting hole. I suspect that this has been broken for some time. Other than frustration induced head slapping, would I damage anything by using it as is while I work out a redesign?

So, unless there's a risk of damage to anything else, I think I'll uses as is while I redesign in bronze; threading with the ebay tap above. Please redirect me if I'm on the way to stupid.

Thanks to all that offered help; the people on this forum are awesome.

So, unless there's a risk of damage to anything else, I think I'll uses as is while I redesign in bronze; threading with the ebay tap above. Please redirect me if I'm on the way to stupid.

I do not think so. You should be just fine. Most of those nuts don't have any provisions for removing backlash at all. Yours has been broken for ages. I cannot see how continuing to use it (without the broken leaf) would do any harm at all. I say go for it!

Proxule

Ultra Member

X2!Thanks to all that offered help; the people on this forum are awesome.

@curmudgeon - did you get this sorted out?

It might be a bit late now but I know Lenmark in Langley has had Grizzly equipment on their site. Whether they can get parts and at what cost is unknown but might be worth a try.

It might be a bit late now but I know Lenmark in Langley has had Grizzly equipment on their site. Whether they can get parts and at what cost is unknown but might be worth a try.

curmudgeon

(Steve)

sadly, no, still unresolved - I have been using it as is and it is frustrating@curmudgeon - did you get this sorted out?

It might be a bit late now but I know Lenmark in Langley has had Grizzly equipment on their site. Whether they can get parts and at what cost is unknown but might be worth a try.

I priced out some brass at Metal Supermarket and have been pouting ever since.

Thanks for the info about Lenmark.

sadly, no, still unresolved - I have been using it as is and it is frustrating

I priced out some brass at Metal Supermarket and have been pouting ever since.

Thanks for the info about Lenmark.

What size piece do you need?

Might be worth asking this eBay seller if they make a Grizzly nut

www.ebay.ca

www.ebay.ca