-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gits 523 Oiler

- Thread starter YotaBota

- Start date

Desab - sorry for the confusion, the right hand column is the model number and to the left on that line are the specs for the oiler I'm looking for. As Brent says, it's 3/8" diameter.

I won't be getting one from MCM anytime soon, minimum order is 5 plus shipping. That would about $130 cdn by the time they were in my hands, maybe I'll just stick a cork in it.

I won't be getting one from MCM anytime soon, minimum order is 5 plus shipping. That would about $130 cdn by the time they were in my hands, maybe I'll just stick a cork in it.

Last edited:

Have you tried eBay?

https://www.ebay.ca/itm/2-NOS-Gits-...iler-Lathe-Machine-Engine-Motor-/164086252766

https://www.ebay.ca/itm/NOS-Gits-3-...er-Lathe-Machine-Electric-Motor-/383426175337

I have a bunch as well but all metric.

https://www.ebay.ca/itm/2-NOS-Gits-...iler-Lathe-Machine-Engine-Motor-/164086252766

https://www.ebay.ca/itm/NOS-Gits-3-...er-Lathe-Machine-Electric-Motor-/383426175337

I have a bunch as well but all metric.

That should have read GITS not MCM.I won't be getting one from MCM anytime soon

John - thanks for the links, I did search ebay and those are about the same cost as buying from MCM. I've just been in sticker shock over the cost of these things but I'm getting over it and will get one.

How about making your own Gits style oiler? The Gits documents show the cross section view.

Or, take the TS spindle out, tap the hole and use either a Delrin or Brass thumb screw with a little O-ring under the shoulder. Unscrew the plug, oil, replace the plug, done.

Or, take the TS spindle out, tap the hole and use either a Delrin or Brass thumb screw with a little O-ring under the shoulder. Unscrew the plug, oil, replace the plug, done.

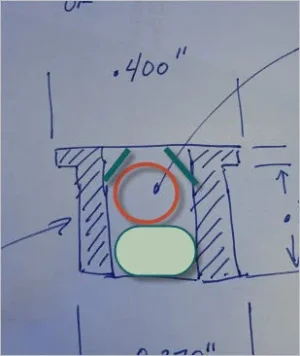

I made one as a test. Basically started with a capscrew. You can drill out the body & make a seat for the ball easy enough. The trick is getting the right (short) spring (green blob on sketch) & retaining it in the body. On the cheapo thin wall brass body ones I think they squish over the lip internal so it keeps the spring in position? Something like that. And thats also where they can get buggered up a bit when being pressed in. I thought about a threaded body because my casting holes vary, likely due to probably offshore hand drilling. Some of the grease zerks I've seen are nice quality but not always low/zero profile which is what my lathe requires at least in certain spots. A raised one wont allow a part or table to move past it.

Attachments

Kelly McLaughlin

Super User

You could just make a brass bushing to adapt whatever size you can easily find as long as it's smaller than the 3/8 The oiler doesn't know it started life as metric : )

I could use the current oiler as the sleeve and drill it out to fit a smaller oiler.

"current oiler" ????

Kelly McLaughlin

Super User

Hi Brent! Sorry I didn't take the time to look at the drawing. Simple is best! At the wildly varying prices of these things find your best deal on a genuine Gits and go for it. after all we're machinists in the making : ) I looked at the off shore ones when I was redoing the Atlas and the quality was suspect, there's some good kit out there but the oilers I saw weren't some of it. in this case boxed in America is the best option : )

The oilers I got from @John Conroy are decent quality and I'm pretty sure he got them on eBay.ca.

https://canadianhobbymetalworkers.com/threads/6mm-brass-ball-oilers.1743/#post-17692

LOT 20 Brass Push Button Press Fit Ball Oiler Grease Zerk Nipple Hit Miss Engine | eBay

Craig

https://canadianhobbymetalworkers.com/threads/6mm-brass-ball-oilers.1743/#post-17692

LOT 20 Brass Push Button Press Fit Ball Oiler Grease Zerk Nipple Hit Miss Engine | eBay

Craig

Last edited:

Kelly McLaughlin

Super User

Hi Craig! I found a fellow on ebay selling Nos so I bought 10 of everything I needed and put the rest in my inventory for the future : ) they're out there but you have to dig. : )

The Ebay ones looks like the offerings on Ali & other sites. I also bought from that seller but I recall it was a long wait & that was way before pandemic was messing things up. I have a feeling they are generically the same until you get into different lines.

You can see the way they form the tube skirt bottom. Its necked in to retain the spring inside. That's what I was referring to about making your own oiler. Not difficult but a bit fiddly. I also found getting the right spring isn't exactly off the shelf - wide OD, thin wire & short length. Unless you want to wind your own....

You can see the way they form the tube skirt bottom. Its necked in to retain the spring inside. That's what I was referring to about making your own oiler. Not difficult but a bit fiddly. I also found getting the right spring isn't exactly off the shelf - wide OD, thin wire & short length. Unless you want to wind your own....