Not a bit John. I just like turning the hand wheels.

Firing up my CNC router is still mildly terrifying. I make air passes on every job so there's no possibility of crashing into anything.

Don't get me wrong, I'd love to have a CNC mill but not at the expense of a manual mill.

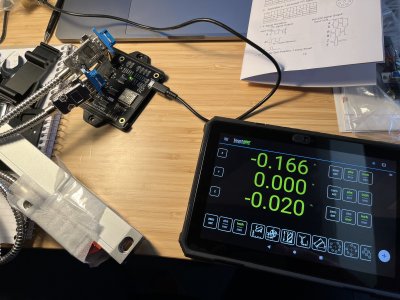

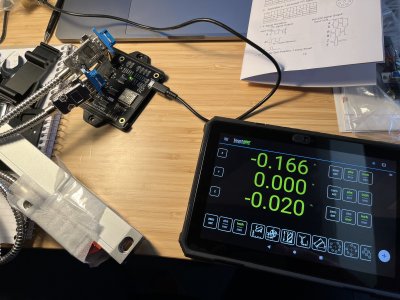

I totally get that. It was the design philosophy behind my lathe ELS. We had many discussions on how to use the same sort of concepts for a mill. At the time I didn't have a mill but another one of the reasons for the DB-25 parallel port connection on the ELS was that with an updated processor it could work for a mill too.

Generally milling with power feeds but no automatic Z axis motion is called 2 & 1/2 axis. The thing that's missing in the manual operation is repeatable simultaneous motion of X and Y. The ability to cut an arc or diagonal line. Most of the time on my mill the rotary table handled the arc side of things. The DRO on XY and the quill served to make it easy to transfer drawings into motion. And the having power feed I always felt was indispensable.

Since I never did go further with an ELS for my mill (although using a Beagle Bone Black with MachineKit was a starting point) eventually I just went CNC, first with MACH3 and then up into LinuxCNC.

And as you saw, with the MDI it's possible to enter in G-Codes and make it move from A to B at a specific rate. Pretty close to a power feed but with a start and end point. But it's clumsy at times. (lots of times). Especially for the one-of project that may only exist as a sketch on the back of an envelope.

What's needed is what I have on my ELS for 2.5 axis milling. Set a BEGIN and END position, configure travel speed and spindle velocity and press START. If you add a powered quill or knee you can add in a RETRACT and CUT position and run a full path. Now START turns on the spindle, moves to the retract position and then to the BEGIN point. Moves to the CUT position and then travels to the END at the travel speed. Pulls out and returns.

Now if you set the Y axis positions to the same value then it's a straight line. If you set them to different positions it's an angular line. And there would be other options for START/END X/Y and a RADIUS. And so on.

The reality is this can all be done with G-Codes on LinuxCNC. What is really needed is just the user interface that gives a user an MPG knob for each axis that behaves exactly like the physical handwheel on a manual machine along with the ability to enter in co-ordinates for more complex motion.

That's where I was headed with the BeagleBone Black until support for MachineKit vanished and the various LCD displays had a support lifetime measured in months. Even the BeagleBone books, if they are are lucky, if they are even being published anymore, have a life of one year. Then the OS is radically modified and the books are instantly out of date.

So I went the PC route and have lived with LinuxCNC. One day my machine might even have ball screws and the monitor will actually bolted to the arm post on the stand.

Anyway, don't discount a CNC installation. Instead grumble about crappy user interfaces.