Let there be light!

Hey David, what is the little black handle above and behind the chuck all about?

Let there be light!

To engage and disengage the drive belt.Hey David, what is the little black handle above and behind the chuck all about?

To engage and disengage the drive belt.

It's fine for me. I use my left hand to push it into place.Huh. Never saw one like that before.

Engaging/disengaging the drive belt from a handle behind the chuck seems a bit risky to me from the other side of the country. What's it like in real life up close and personal?

It's fine for me. I use my left hand to push it into place.

No. When it's toward the operator the belt is disengaged.With the chuck spinning?

No. When it's toward the operator the belt is disengaged.

Starts to engage when the handle is vertical.

I feel totally safe doing it. As soon as you take the tension off the chuck spins down.So you pull it toward you with the chuck spinning?

I think you get the concern. Looking at the photo, it looks risky. The chuck either spins up and grabs your sleeve when you engage it or it drags you into the chuck when you disengage.

What I was trying to ask is if it is safer in reality than it looks in the picture?

I don't use it very often. Mostly I do the same as you, loosen the belt to change speeds. When I switch to 3-phase I won't even have to do that.Mine is like that as well but I only use it to move the belt to change speeds, not to engage the chuck.

I feel totally safe doing it. As soon as you take the tension off the chuck spins down.

When I use it I'm very aware of where my hands and never use it if I'm in a hurry.Kinda what I figured had to be the case. After all, we all play with the business end. It just looked a bit risky.

I use mine as a bit of a "I'm a dumbass" safety feature.Kinda what I figured had to be the case. After all, we all play with the business end. It just looked a bit risky.

I also do not tighten/loosen the belt when the motor is running. I tighten the belt and then use the "engagement" lever on the saddle to start it up in either forward or reverse. Take the tension off the belt to help prevent belt stretch.I have the same lathe, but I've never moved the handle while the motor was running... I'm too chicken!!

I have the same lathe, but I've never moved the handle while the motor was running... I'm too chicken!!

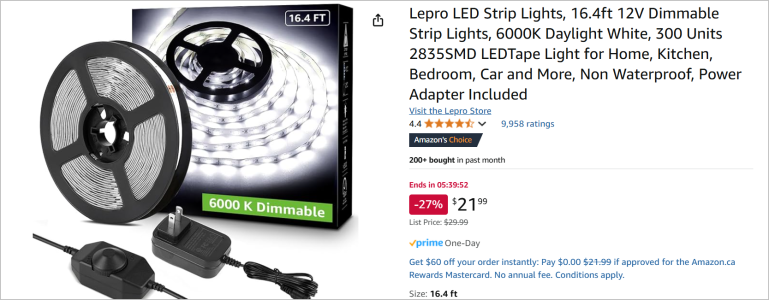

I've been utilizing something similar for a while. Maybe you have done the same but I use an LED type bulb because they are brighter, run cool, less risk if you get a spritz of liquid which thermally shattered one of the old school bulbs. They can still break if something hits them so check if plastic or glass. Even so, those study lamps aren't the best for machining IMO. Amazing how chips get inside the vent holes or in behind the bulb.Let there be light!

Maybe you have done the same but I use an LED type bulb because they are brighter, run cool, less risk if you get a spritz of liquid which thermally shattered one of the old school bulbs.

I'll keep you posted