If anyone needs a shop project, make up one of these tear dropped shaped pieces. The slot in the bottom lets you move the chain to be different lengths, or add a second chain even. It’s awesome for how versatile it is, plus it takes the sketchy out of moving things around.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Daily Shop Improvement

- Thread starter Janger

- Start date

View attachment 8625

If anyone needs a shop project, make up one of these tear dropped shaped pieces. The slot in the bottom lets you move the chain to be different lengths, or add a second chain even. It’s awesome for how versatile it is, plus it takes the sketchy out of moving things around.

Why not offer some idea of the dimensions perhaps along with a stand alone picture and the size of chain used. Did you make it or buy same, and where??? Bill

Why not offer some idea of the dimensions perhaps along with a stand alone picture and the size of chain used. Did you make it or buy same, and where??? Bill

I’m pretty sure the first one I found on the side of the road. If you take a close look at a municipal truck with a snow plow they use something similar. The following two I had made up, one decided it was ready to find a new home.

I use 1/4” G70 chain, never had any issues yet. Yes I know G100 is lifting chain, I’m not gonna sweat that.

I try to choke the chain back on itself, I feel it’s safer that way. Not saying it’s “right”

Another option is to buy weld on grab hooks, weld them to a flat plate, and torch a hole. What I did here was get two 1/4” G70 chains, put slip hooks on the ends, and now I have four hooks on four legs. I can move pickup truck boxes, flat beds, machinery, anything that you want to keep level while you’re moving it

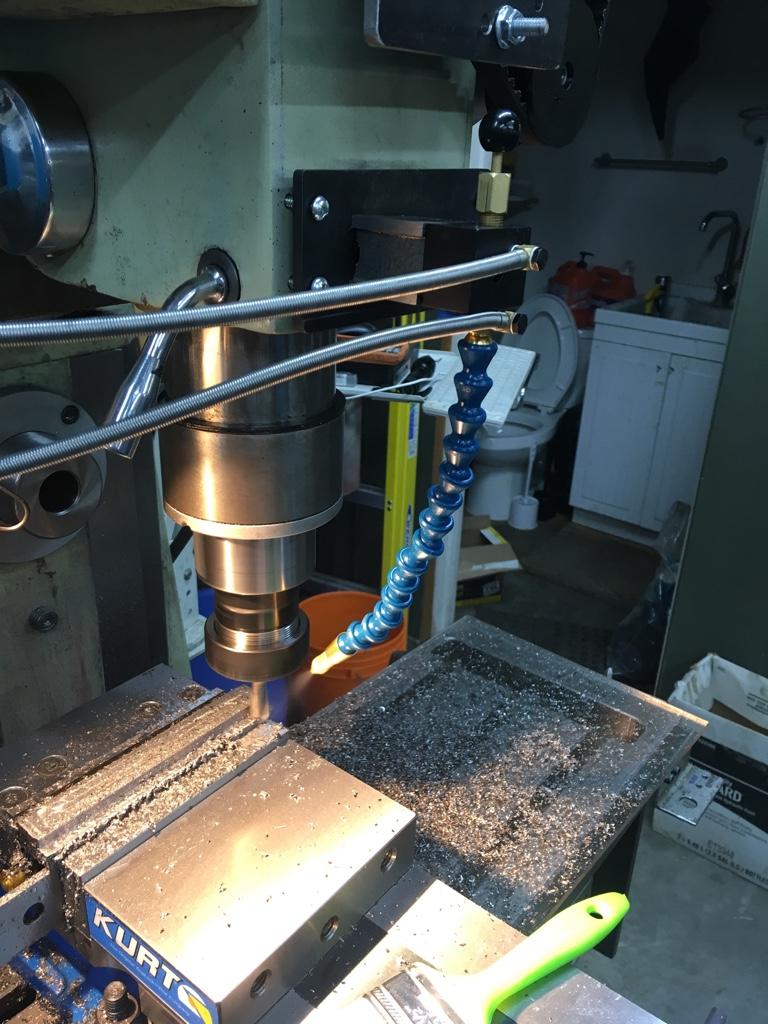

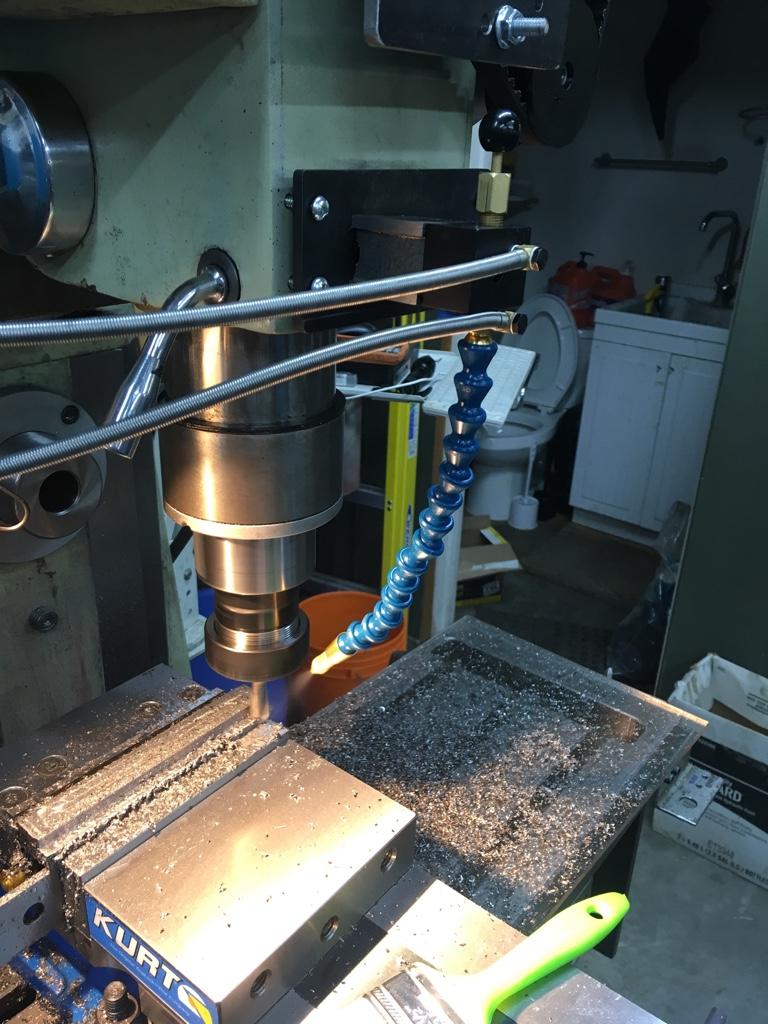

ER fixture for tightening collets (this one is er40).

Now I can get the torque required

Sent from my iPhone using Tapatalk

Update: bad design. Bent the fixture arm when tightening collet, landed on my ass, bruised my pride!

@Janger sketched a better design. Please post as that will be way better

Sent from my iPhone using Tapatalk

Update: bad design. Bent the fixture arm when tightening collet, landed on my ass, bruised my pride!

@Janger sketched a better design. Please post as that will be way better

Sent from my iPhone using Tapatalk

Last edited:

Replaced the broken casters on my mechanics stool, and replaced the other two that probably aren’t far behind.

Wandering around TSC this morning I added to my funnel collection.

@YYCHM, like that I assume this is on a 5" x 6" bandsaw. Shall consider doing a similar upgrade how thick is your plate steel?

Seems to me you fit a narrow piece of brass in the blade slot. What cutting advantages are there in doing that? Bill

3/8" plate, I just picked what ever I had that was closest to the regular jaws for thickness.

The blade slot is filled with hardwood, not brass. I cut a lot of little stubby short pieces of stock that without support under the blade tends to tip into the blade slot. The hardwood fill is my solution to the tipping and seems to work.

As a bonus, the slot in the hardwood the blade leaves is real handy for lining up stock for a cut.

Craig

@YYCHM - when my knee heals properly and I get back into my shop before my next surgery this project is high on my to-do list.

I like the use of wood in the blade slot and cheap to replace. The only downside if you could call it that is metal cuttings don't have a slot to fall through, no big deal there! Like you I cut a off lot of small pieces mostly from scraps I've picked up. I always try to use up my scraps before cutting from my limited stock selection which has paid off.

Thank you Bill

I like the use of wood in the blade slot and cheap to replace. The only downside if you could call it that is metal cuttings don't have a slot to fall through, no big deal there! Like you I cut a off lot of small pieces mostly from scraps I've picked up. I always try to use up my scraps before cutting from my limited stock selection which has paid off.

Thank you Bill

During my recent moves, it became necessary to lift from the bottom of the load in some cases, so I whipped together a quick set of lifting bars:

If you make your own a few design points:

make them extra long: Mine are 36" with 33" centre to centre on the bolts

- you need the extra width for a pallet jack. Modern tool's are a little too narrow.

The thread is 3/4 NF, and that allows an normal Dewalt drill to lift the 900 lb Bridgeport base in lower gear.

- the larger lower nut is necessary to use a wrench on the bolts.

- It is only hand tight in case it needs to be removed (for some reason)

Safe lifting distance without bracing is about 6 inches. the bolts are 8" long

If you make your own a few design points:

make them extra long: Mine are 36" with 33" centre to centre on the bolts

- you need the extra width for a pallet jack. Modern tool's are a little too narrow.

The thread is 3/4 NF, and that allows an normal Dewalt drill to lift the 900 lb Bridgeport base in lower gear.

- the larger lower nut is necessary to use a wrench on the bolts.

- It is only hand tight in case it needs to be removed (for some reason)

Safe lifting distance without bracing is about 6 inches. the bolts are 8" long

Today...I fixed my band saw vise. It just needed grease so the nifty nut engager would work again. Very clever mechanism.

I cleaned up the way my air tools are setup. I also discovered my new 3/8 NPT Air regulator Princess Auto brand leaks through the knob. Any body find that model works?

What about this:

https://www.amazon.ca/EXELAIR-Milton-FRL-Air-Regulator/dp/B01MCT9E2X/ref=sr_1_3?crid=3BNJ3VMMM2H1K&keywords=milton+air+regulator&qid=1587090922&sprefix=milton+air+reg,aps,243&sr=8-3

Any thoughts if this is any good ?

I cleaned up the way my air tools are setup. I also discovered my new 3/8 NPT Air regulator Princess Auto brand leaks through the knob. Any body find that model works?

What about this:

https://www.amazon.ca/EXELAIR-Milton-FRL-Air-Regulator/dp/B01MCT9E2X/ref=sr_1_3?crid=3BNJ3VMMM2H1K&keywords=milton+air+regulator&qid=1587090922&sprefix=milton+air+reg,aps,243&sr=8-3

Any thoughts if this is any good ?

First I installed O-rings on the ends of my chuck key handles so I could vary the length on the fly & they would no longer fall out or require me to diddle with the set screw. I couldn't quite get the fit I was after though. I think I should have made a conventional square groove so the O-ring would stay put. I used a rounded cutter that didn't really match the O-ring section diameter. Then I remembered I had these silicone end plugs. I'm not even sure what they are used for but I used them to electrically insulate the live ends of RC lipo battery packs when not in use. Anyways, they pushed on tight & that was that. Ugly but functional. If only had different colors! lol

Attachments

The thread is 3/4 NF, and that allows an normal Dewalt drill to lift the 900 lb Bridgeport base in lower gear.

That's smart - using a cordless drill or impact wrench & just power jack them up or down. Saves a lot of socket ratchet work.

I cant quite tell - did you machine flats on the threaded rod or weld nuts on?

NOGA mister installed today, works good, makes a mess though but I can deal with that

Running cnc programs to make t-nuts for shaper, long running , this helps as it is constant

Sent from my iPhone using Tapatalk

Running cnc programs to make t-nuts for shaper, long running , this helps as it is constant

Sent from my iPhone using Tapatalk

4oz per gallon of water

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk