You got access to a tooling supplier in your area that deals in inserts? Might be worth talking to one of the sales guys about an appropriate selection. Carbide grade, quality, coatings, and edge treatment, as well as nose radius, all can make or break some jobs.You like inserts too eh?

Maybe my lathe experience makes me paranoid. I wouldn't expect to get away with using inserts on high strength material with interrupted cuts. So I just figure no way will those face mill inserts cut that forging without breaking.

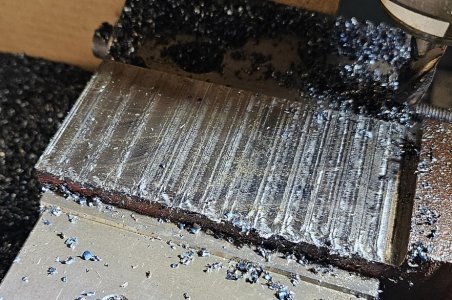

I'm about 1/3 done. It seems wiser to just keep going.

But if I break another endmill, I'll try a face mill with big inserts. Why not.......

A friendly scrap metal dealer with an x-ray fluorescence gun, could sort you out real quick on what the stuff actually is as far as an alloy at least.

The Monday deadline would likely have me reaching for the ugliest angle grinder I had on hand and start beavering away at it. Ugh.