-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machine Considering Buying a King 1236ML Looking for Opinions

- Thread starter Jason Silliker

- Start date

Machine

Jason Silliker

Active Member

Bit of a side story, when I bought the Level, I didn’t notice it was a non-returnable item which makes sense I guess. I contacted Amazon because the adjustment screw is at an angle inside, while it does adjust I’m not sure if it’s adjusting it correctly. I ended up contacting Amazon told them of the issue and she said to send pictures so I did and they refunded me. I’m going to revisit it in the future. I’m sure it’s more me than the level. I just found it weird that it couldn’t be proved, but I think even levelling the piece in the vice to get it on plane one way, it’s probably so damn sensitive just turning at 180 and setting it back down may not have been good enough.@Jason Silliker nice get on the lathe!

I have 2 Moore and Wright levels, .003 per foot. they work very well, as I'm sure the Starrett does as well. I did make a mistake buying a .0002 per foot level. uncalibrated. never used. The adjuster was permanently loctited out of calibration. To break it free, I would have to melt a plastic part. Sure I could rebuild it, but why bother? I was naive buying it, and have even refused to sell it to a friend when he wanted to buy it for full price.

After you get to .003, you have to get closer by taking cuts anyway...

Jason Silliker

Active Member

Yeah, like I mentioned, that’s all I have in my drill press, it was a very cheap aquarium pump with 3/8 tubing and an empty coffee can with a large screen filter as a cover. Catchers on knee tips that come back through the 1” return hose. I don’t use it often but it works really well. I’ll have to look, but I think I may have a second pump here already like I said I have two of the free misters. The brush method works fine so far for me like I said I’ve done very very little. Just playing a little bit getting used to it. Knowing me, I’ll set it up and rarely use it, but it will still be there lol.Avery inexpensive coolant system can be cobbled together using a common fish tank or garden pond submersible pump. the smallest volume you can find will work and even then will have way more pressure than you need but that is easily remedied, Just install a brass needle valve in your piping and excess pressure can be easily diverted back to reservoir ( in my case an old 5 gal pail).

I make the "return drain' so that it just lays at the bottom of the pail . this facilitates return line cutting chips just lay/settle on the bottom of the pail and I keep the submersible pump up near the top of the fluid level so no damaging crud is sucked into it.

I doubt if my hole set-up costs more than $50 at the time ....but that was almost 20 yrs ago.

Jason Silliker

Active Member

@Susquatch I appreciate your offer as well but the shipping to PEI would be a killer, but thanks again.Yep they will. I know. They did. Sending you a PM re shared shipping.

@Susquatch I appreciate your offer as well but the shipping to PEI would be a killer, but thanks again.

I'll let you know the full damages when it arrives. You might as well pay UPS too. Stuff is worth its weight in gold. The slinging alone is worth the cost.

I followed Susq’s advice a few months ago and got some Viper Venom from Grizzle. It only took about a week to arrive. No issues with shipping an oil. Normal UPS brokerage/shipping rip-off but no biggie.

This stuff is every bit as good as Susq claims.

I set up a mister on my mill a year ago using water soluble lube (Coolcut S50 manufactured by Walter, $105 from S B Simpson for 3.8 l). The mister works really well and is easy to control both % liquid and volume of air. But I don’t like it. It’s messy, smells, plus water and iron don’t play well. But the biggest draw back (which was recently pointed out to me by Torontobuilder) is the mould and mildew potential hazard. My mister is now only an air nozzle.

The mister is on a magnet base and very easy to reposition:

Here’s my cutting oil choices. I usually mix A-9 with 50% wd40 (for aluminum).

This stuff is every bit as good as Susq claims.

I set up a mister on my mill a year ago using water soluble lube (Coolcut S50 manufactured by Walter, $105 from S B Simpson for 3.8 l). The mister works really well and is easy to control both % liquid and volume of air. But I don’t like it. It’s messy, smells, plus water and iron don’t play well. But the biggest draw back (which was recently pointed out to me by Torontobuilder) is the mould and mildew potential hazard. My mister is now only an air nozzle.

The mister is on a magnet base and very easy to reposition:

Here’s my cutting oil choices. I usually mix A-9 with 50% wd40 (for aluminum).

Last edited:

But the biggest draw back (which was recently pointed out to me by Torontobuilder) is the mould and mildew potential hazard.

I keep forgetting about that. The irony isn't lost on me though. The world thinks water based is soooo much better for you. And then the mold and slime monsters arrive..... I guess its ok for those who do enough work to keep the tanks fresh or maybe those without any respiratory challenges. But that aint me. Then you consider how well it actually works.... Ya, give me the good stuff all day long.

Thanks for the timely reminders Craig. And a thank you to @TorontoBuilder too.

There is a youtube channel called "Adam the Machinist". He is every bit as knowledgeable and acccomplished as Renzetti. He converted his HAAS mill to use cutting oil as a coolant, and has a long list of reasons why, despite it being "not recommended" by HAAS, and people in the industry saying fire would be an issue (it wasn't).

I'm having some difficulty finding 'that' video, but I know I captured it, so I'll post a link when I figure it out.

This is a guy whtat works regularly to a then thousanth of an inch on every dimension on complex parts. Worth giving him a try.

I'm having some difficulty finding 'that' video, but I know I captured it, so I'll post a link when I figure it out.

This is a guy whtat works regularly to a then thousanth of an inch on every dimension on complex parts. Worth giving him a try.

HIs channel is excellent! Very aspirational.There is a youtube channel called "Adam the Machinist". He is every bit as knowledgeable and acccomplished as Renzetti. He converted his HAAS mill to use cutting oil as a coolant, and has a long list of reasons why, despite it being "not recommended" by HAAS, and people in the industry saying fire would be an issue (it wasn't).

I'm having some difficulty finding 'that' video, but I know I captured it, so I'll post a link when I figure it out.

This is a guy whtat works regularly to a then thousanth of an inch on every dimension on complex parts. Worth giving him a try.

Jason Silliker

Active Member

Been busy with a few different projects haven’t got to do a whole lot lately. Turn the piece of round stock to a 60° point for a quick and dirty tool height adjuster. Still planning on making a proper version. I did make a handle to replace the nut on the top of the quick change tool post. Had some stainless here. Come out pretty good. I am going to shorten it and add a plastic handle in the future to match a little closer. Pretty impressed how well it cut stainless.

Attachments

Jason Silliker

Active Member

Playing around with some different ideas for most often used tool storage. I was gonna use PVC pipe, but decided to use a lot of thin wall tubing I have laying around and I have various thin wall square and rectangle tubing from treadmills that have been junked. Started with a piece of 1/8 plate bent two 1” sides and started playing around. I removed two of the bolts in the top cover of the gearbox and used two longer bolts to hold this in place. Just put a few things in the back row for now that’s why the rest of it’s not painted until I finish adding what I want to add.

Attachments

Pretty impressed how well it cut stainless.

This is a complaint I hear often. I really don't understand it. I've never had a problem with any grade I've turned. Maybe just lucky. Sounds like you might be too!

Brian H

Super User

I have a King 1236 lathe that I purchased new just over 1 year ago. It has been a really good machine for my needs (all hobby work). I have been really happy with it. Recently I had the lead screw transmission pile up due to casting sand in the oil ports and King looked after sending all the new pieces I required. Got it all back up and running again in about 6 weeks (Canada post strike).

I wouldn't hesitate to recommend it to anyone.

I wouldn't hesitate to recommend it to anyone.

Jason Silliker

Active Member

I had this coolant pump (rarely used) hooked up to my drill press. Figured for the sake of a fitting and a little bit of tubing might as well hook it up so we can do both the lathe and the drill press. Just 40 to 1 cutting oil on it now. I’ll switch to something better later. Probably won’t get used a lot, but we’ll see.Also threw together a brush holding rack.

Attachments

Jason Silliker

Active Member

Works pretty good, lots of flow. It’s only on about halfway here just to keep the splashing down.

I have one of the stainless style nozzles coming. This one works OK, but the stainlessones tend to be a little stiffer and not leak.

I have one of the stainless style nozzles coming. This one works OK, but the stainlessones tend to be a little stiffer and not leak.

Attachments

Jason Silliker

Active Member

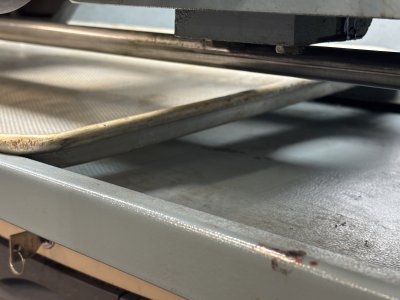

Hey guys it’s been a bit…haven’t been doing a lot of machining lately. I grabbed a commercial perforated baking sheet today. It’s 18”x 26” (18x32 would have been perfect) It fits in nicely and leaves a 1” or so gap to the bed for the coolant to drain out. It easily slides so if I ever need that extra few inches. Makes for easy clean up of chips and was only a whole 5 bucks lol.

Attachments

If you have a choice in tray I would not go perforated. Its just asking for swarf to stick into (hard to brush out & ouchy on the hands). And fluid drippings to leak out. You can also get plastic cafeteria style trays pretty cheap at some of the discount sellers. That's what I'm using & they are very tough. We have a place called Wholesale Foods where you can source that kind of stuff. I also get other shop goodies like plastic sauce / condiment / take home? plastic containers (great for holding washing small parts), paper cups (mixing paint, epoxy whatever) stir sticks... And well stuff for the kitchen too, of course LOL

Jason Silliker

Active Member

Thanks lol. I just found out the holes aren’t the way to go. I was glad I grabbed one of each. I marked where my drip pan hole is and add a dozen little small holes and dimple the tray there to let any coolant out. Anytime there’s anything in it. I’ll just let it drip out for the night and dump it the next day.

Attachments

Jason Silliker

Active Member

Any suggestions or preferred DRO's? Something middle of the road?