Brent H

Ultra Member

Great day making gears today. Spent yesterday making blanks and cursing the failed broach fiasco and then came today!!!

cutting gears to replace the missing parts in my tool grinder. The slow feed in my model was supposed to have helical gears - hard to make, so I made spur gears as would have been the way of the 1930’s models. Since they didn’t change the casting for the handle I could revert to the old gearing.

I made a new stationary gear shaft from 1-1/2” 4140 with bushing pressed into either end to support a 3/4” shaft that drives a bronze gear. This gear moves the rack back an forth while grinding. This shaft received 19 gear teeth. 14DP - 14.5° PA.

Then I machined the broached blank with 20 Teeth - all same cutter so set up was quick and easy.

I then cut the spool with 18 Teeth on one end and 17 teeth the other.

Then we had some assembly time:

The smaller gears are Cast Iron.

I lubbed up everything with some assembly grease and put it on the machine.

Works like a charm!!

You push in the centre shaft to engage the slow gear and it rotates on the bigger shaft to reduce the feed speed - I forget the amount sorta 4-1 type thing.

I would like to make a new bronze drive gear for this machine but having trouble finding a 12 DP -20°PA cutter. Most are the 14.5°.

Anyway - new belt to install and hook up the VFD and should be good to start wrecking end mills very soon!!

cutting gears to replace the missing parts in my tool grinder. The slow feed in my model was supposed to have helical gears - hard to make, so I made spur gears as would have been the way of the 1930’s models. Since they didn’t change the casting for the handle I could revert to the old gearing.

I made a new stationary gear shaft from 1-1/2” 4140 with bushing pressed into either end to support a 3/4” shaft that drives a bronze gear. This gear moves the rack back an forth while grinding. This shaft received 19 gear teeth. 14DP - 14.5° PA.

Then I machined the broached blank with 20 Teeth - all same cutter so set up was quick and easy.

I then cut the spool with 18 Teeth on one end and 17 teeth the other.

Then we had some assembly time:

The smaller gears are Cast Iron.

I lubbed up everything with some assembly grease and put it on the machine.

Works like a charm!!

You push in the centre shaft to engage the slow gear and it rotates on the bigger shaft to reduce the feed speed - I forget the amount sorta 4-1 type thing.

I would like to make a new bronze drive gear for this machine but having trouble finding a 12 DP -20°PA cutter. Most are the 14.5°.

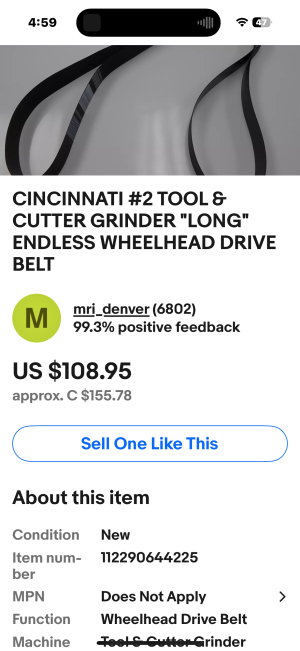

Anyway - new belt to install and hook up the VFD and should be good to start wrecking end mills very soon!!