I am sooooo tempted to get one for my basement shop. Mostly for reloading and case prep......

Use it to do what specifically? I can't picture a mini-lathe replacing any of your reloading tools.

I am sooooo tempted to get one for my basement shop. Mostly for reloading and case prep......

Use it to do what specifically? I can't picture a mini-lathe replacing any of your reloading tools.

Do you have a Taig or similar?I don't want to put a lot on the forum but just picture turning case necks to a uniform thickness +/- a tenth alone. Right now I do it manually. Lots and lots of other very similar tasks well suited to a very small lathe with a powered spindle. Right now I have three tiny little manual lathes for these purposes. Some folks power them with a drill or a dedicated drive motor. Back in the day when such practices were developed there were no small lathes like this and for those who had a real lathe, it was much bigger.

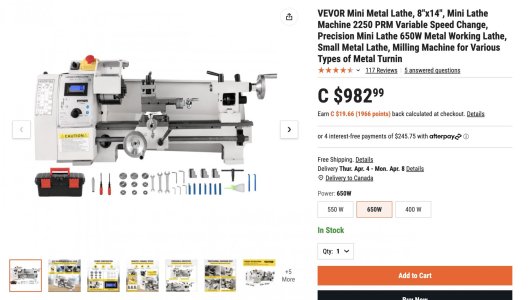

Dang, I wished my lathes had come with "1 x Set of Fitting"The 7x12 550w - US version comes with:

- 1 x Set of Fitting

Just curious how you would hold the brass to turn the necks? If by tenth, your meaning .0001”, that’s pretty tight tolerances for a Chinese lathe I would think.I don't want to put a lot on the forum but just picture turning case necks to a uniform thickness +/- a tenth alone. Right now I do it manually. Lots and lots of other very similar tasks well suited to a very small lathe with a powered spindle. Right now I have three tiny little manual lathes for these purposes. Some folks power them with a drill or a dedicated drive motor. Back in the day when such practices were developed there were no small lathes like this and for those who had a real lathe, it was much bigger.

Just curious how you would hold the brass to turn the necks? If by tenth, your meaning .0001”, that’s pretty tight tolerances for a Chinese lathe I would think.

for your next custom rifle you should consider chambering it for Lapua brass using a no turn neck (with the exception of PPC).

But I digress, I am getting off topic from the original post.

cheers

I tried using a mini lathe I owned ( sold to a very fine forum member) at one time for brass trimming but it was a dismal failure for me altho it was no fault of the machines it was just my failure to properly build the holding devises needed to hold everything solidly in place for the job ...

@Susquatch What cartridges do you have with Lapua brass?