-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brent Builds!!

- Thread starter Brent H

- Start date

Brent H

Ultra Member

The next “shop” project will be to get the Cincinnati No. 2 cutter grinder set up and full on running. Probably be a week of sharpening stuff after that -

LOL. then I have to start on the car and the bar …..

I was in Quebec Side by Siding with my buddies and blew a belt out of the back of the clutch housing - UGH! I ordered parts but they are months away. Bent up some stainless and made a patch for the time being:

I smoothed out the liquid gasket after it set for a bit. Hopefully water tight and we can get back to driving around like a nut !

LOL. then I have to start on the car and the bar …..

I was in Quebec Side by Siding with my buddies and blew a belt out of the back of the clutch housing - UGH! I ordered parts but they are months away. Bent up some stainless and made a patch for the time being:

I smoothed out the liquid gasket after it set for a bit. Hopefully water tight and we can get back to driving around like a nut !

Brent H

Ultra Member

So my cousin needed a “tiller head” for his fish sonar. No better time than to mill up a big hunk of aluminum. This is a 3 inch x 4-1/4” piece of round stock:

So after the above operations I used a slitting saw to slice a slot between the stainless cap screws so the piece would clamp onto the tiller leg. Using a short piece of the round tubbing I mounted the assembly into my dividing head. I used the dividing head to round the body.

There is a handle that mounts in the slot. The assembly fits into that aluminum plate with a tapered bushing.

I was hoping to show the whole assembly but my cousin was so excited about how things turned out that it was all packed up and off to mount on his boat when I went to get a pop - LOL.

Basically the sonar mounts to the bottom of the tiller and you can direct the beam to find the fish.

So after the above operations I used a slitting saw to slice a slot between the stainless cap screws so the piece would clamp onto the tiller leg. Using a short piece of the round tubbing I mounted the assembly into my dividing head. I used the dividing head to round the body.

There is a handle that mounts in the slot. The assembly fits into that aluminum plate with a tapered bushing.

I was hoping to show the whole assembly but my cousin was so excited about how things turned out that it was all packed up and off to mount on his boat when I went to get a pop - LOL.

Basically the sonar mounts to the bottom of the tiller and you can direct the beam to find the fish.

I was hoping to show the whole assembly but my cousin was so excited about how things turned out that it was all packed up and off to mount on his boat when I went to get a pop - LOL.

I was all excited too! And then you started welding in the second last photo and suddenly, all my excitement went overboard......

Aluminium no less.

Brent H

Ultra Member

@Susquatch : I have a spool gun for my welder. As this was pretty thick stuff I had it cranked up to 180 amps, argon gas and 0.030 Al Super Glaze 4043

The above pic is the stainless power box I bent up for the brains of the operation.

The above pic is the stainless power box I bent up for the brains of the operation.

Dan Dubeau

Ultra Member

Nice work. The fish don't stand a chance now.

I have a spool gun for my welder. As this was pretty thick stuff I had it cranked up to 180 amps, argon gas and 0.030 Al Super Glaze 4043

Well, about all I can really say is that I am insanely jealous of your talents. Even with a spool gun, about all I'd accomplish would be a pile of rehardened molten metal on the floor.

Dan Dubeau

Ultra Member

Squatch, you need to get a welding robot, and rotary positioner. Lean into your Computer/programming knowledge, and remove the variables.....Some of the smaller robotic arms would be perfect for this.

Squatch, you need to get a welding robot, and rotary positioner. Lean into your Computer/programming knowledge, and remove the variables.....Some of the smaller robotic arms would be perfect for this.

I laughed when I read that. Not cuz it's really funny, but rather because it's soooooo not me.

I actually installed and setup some of the first welding robots we had in the Auto industry. I even held patents on some of the technology.

Today I want to be as far away from Robotics and CNC as I can get. That might be why I like turning handwheels now. Basically, I retired from that world and don't want to go back. I enjoy a much simpler all manual world now. And I have all the time in the world to do it. So even if a robot could cure my vision, skill, and coordination problems, I still wouldn't do it.

I don't know if anyone else can truly appreciate that, but here is an analogy that might help. Imagine that I made my living as a commercial fisherman on a trawler for 40 years. On retirement, I still like fishing, but don't want the big boats and nets anymore. Now I'm happier with a rod and reel on a quiet lake listening to the loons. On occasion, I might even put some bait on my hook......

But don't get me wrong. That doesn't affect my ability to be jealous of guys like you who can actually make welds that work and look good too. I just don't think it's something I will ever be able to do very well.

Here is a visual for that. Try welding with a patch on your left eye and a motorized eccentric on both forearms.

Brent H

Ultra Member

@Susquatch - you are very correct, I worked on the water for 33 years and I love to fish but I don’t and never have owned a boat - LOL

Dan Dubeau

Ultra Member

I can understand that. Most of my career was spent trying to modernize and do things more efficiently against the wishes of stubborn old toolmakers that didn't want to change, but just kept leaping from one sinking ship to another as we couldn't keep up with competition, foreign and domestic. I wanted to CNC everything, they, Including owners, didn't. It was always a tougher battle than it needed to be, but I had many victories I'm proud of.

Now in my home shop I actually enjoy cranking handles again. Never thought I would enjoy manual milling again after utilizing CNC for so many years, but I turn to it WAY more than the CNC mill sitting next to it. I do different kind of work than I used to, but still, in my home shop there is really no cost justification for anything. Just for pure enjoyment of building stuff. Having the CNC option still opens up a lot of possibilities too, It's really nice to just let it eat away while I do something else, but for most general milling, it's handles.....Now, if I could only find a reasonably priced and local 10-12 H/V rotary table.....

Now in my home shop I actually enjoy cranking handles again. Never thought I would enjoy manual milling again after utilizing CNC for so many years, but I turn to it WAY more than the CNC mill sitting next to it. I do different kind of work than I used to, but still, in my home shop there is really no cost justification for anything. Just for pure enjoyment of building stuff. Having the CNC option still opens up a lot of possibilities too, It's really nice to just let it eat away while I do something else, but for most general milling, it's handles.....Now, if I could only find a reasonably priced and local 10-12 H/V rotary table.....

Yep, me too Sus but luckily it came to me fairly early in my career and is so far out of the financial realm of possibilities in retirement that it isn't even a thought. Starting out there was a drive to fly higher, faster and farther. You might do all that in a Lear 45 but when you're close enough notice any of that you're below 200 knots anyway and there's always someone beside you and the nobs in the back. Now rolling into a 45* bank to fit between a couple of trees on short final into a tiny lake behind a 75 year old radial engine, that's bliss.

I think if have to make 50 of the same widgets I’d like CNC.Today I want to be as far away from Robotics and CNC as I can get.

Until then I’d prefer manual, though a DRO on the mill will be excellent.

Brent H

Ultra Member

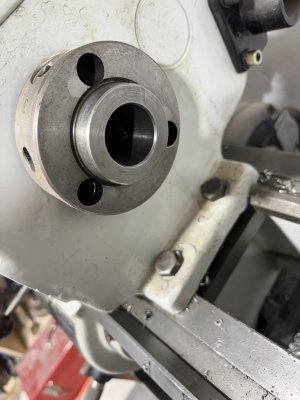

For the folks out there with a Utilathe (10/12”) with a D1-3 headstock, the internal taper is a M4.

Given the government situation and steel etc I ordered a set of M4 collets from ebay on a decent deal from the states. 1/8 to 1”. They are not “through” collets but will certainly hold small pieces and give me maximum length of the lathe bed.

Packing was great and they arrived in good time and in good condition. The idea is that the collet fits perfectly into the D1-3 nose

And can then be secured with a long rod with 5/8-11 threads connected to a hand wheel and drawn tight against the main shaft.

This was a feature of the larger Utilathes (11/13) that changed the D1-3 to the D1-4 chuck mount and thus an M4 to M5 collet. When we picked up @architect ’s 11” lathe it came with the draw tube/ handle for the lathe and it got me thinking!

Anyway, I will update as I can… deck building is going down, new air compressor chain falled into the attic, neighbours pool has a new liner, and gotta get milling wood - oh and a san blast station to set up … etc etc

Given the government situation and steel etc I ordered a set of M4 collets from ebay on a decent deal from the states. 1/8 to 1”. They are not “through” collets but will certainly hold small pieces and give me maximum length of the lathe bed.

Packing was great and they arrived in good time and in good condition. The idea is that the collet fits perfectly into the D1-3 nose

And can then be secured with a long rod with 5/8-11 threads connected to a hand wheel and drawn tight against the main shaft.

This was a feature of the larger Utilathes (11/13) that changed the D1-3 to the D1-4 chuck mount and thus an M4 to M5 collet. When we picked up @architect ’s 11” lathe it came with the draw tube/ handle for the lathe and it got me thinking!

Anyway, I will update as I can… deck building is going down, new air compressor chain falled into the attic, neighbours pool has a new liner, and gotta get milling wood - oh and a san blast station to set up … etc etc

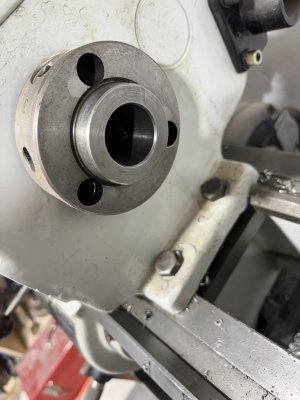

I like having the SB 5C collet holder. The thread guard screws on. Then the adapter goes into the taper and then the collet. Doesn't stick out nearly as far as the chuck or even the face plate.Nice work @Brent H

I'm thinking about doing the same thing but with a shop made adapter for 5C collets.

Like this:

I've got a lovely chunk of 4140 all ready to go 🙂I like having the SB 5C collet holder. The thread guard screws on. Then the adapter goes into the taper and then the collet. Doesn't stick out nearly as far as the chuck or even the face plate.

View attachment 64407

I've got a lovely chunk of 4140 all ready to go 🙂

You guys…..

Another project for the to do wish list! 😀

D 😎