Matt-Aburg

Ultra Member

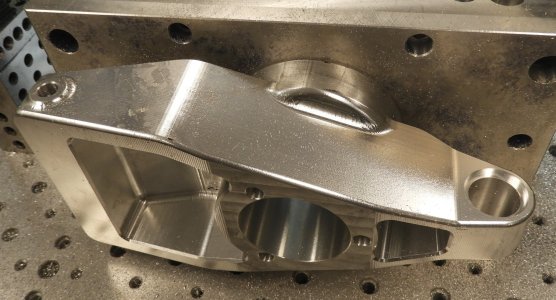

The fixture is very simple. I use the two dowels for alignment and location. The standing aluminum is only so the three 1/4-20 holes are only 0.05 away from the pocket in the housing (clear both top and sides). On the old fixture I was using the six 5/16-18 holes on the flange of the housing. The two problems were, having to remove the fixture each time to undo it, and also the fixture was 3 inches thick, limiting my cutter length. The Version 1 of this part was whole, with no sleeve. I changed the part because the alignment between front and back bores is critical on the part. As a whole, it was impossible to clock the opposite bore. Also impossible to check afterwards. I will still be using the original fixture for side and end operations.The ball mill finishing made it look great Matt. They're not paying you enough that's for sure. :> but that's not entirely why you're doing this! Labour of love clearly.

Show us another picture of the fixture without the part? I don't follow how it works.

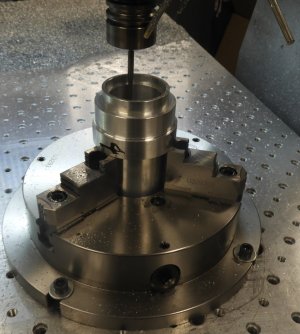

The final housing is being machined now. Next job will be to finish the sleeve bushings. This will be a surprise as you see the tooling I will be using to do it........