Matt-Aburg

Ultra Member

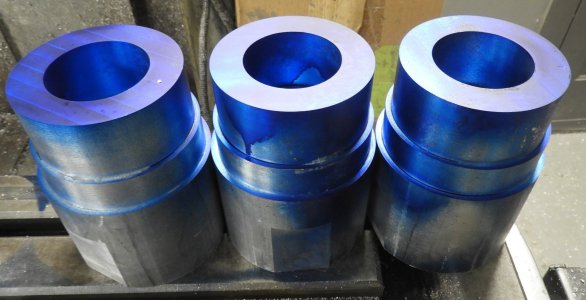

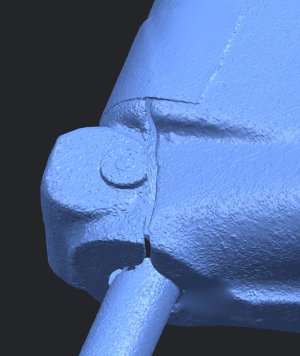

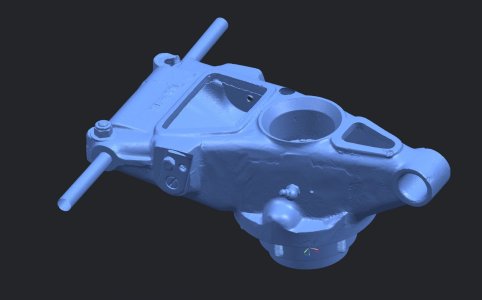

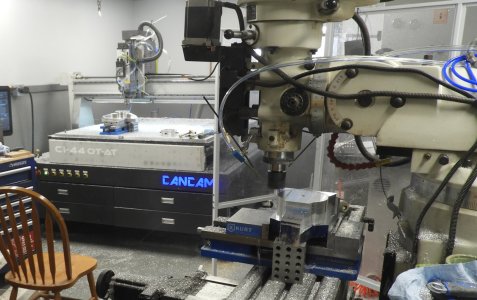

Finishing operation # 2

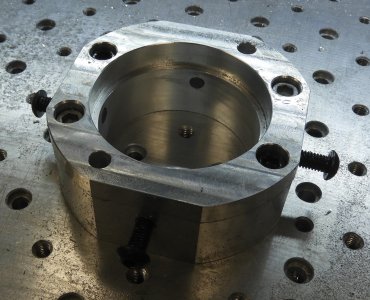

This is done on a fixture. I am thinking about re-investing my pay form this job into 4 more billets and 1 new fixture plate that will cut 2 at once....

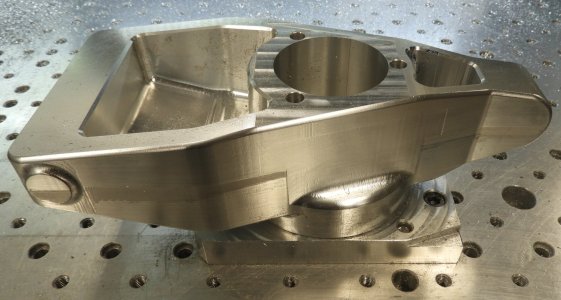

Anyway here is the almost finished product. I have side, end, and other holes to go in. Toughest will be the 6 deep 0.500 ream. I am thinking about getting my friend with real CNC's to help me out on the deep drilling....

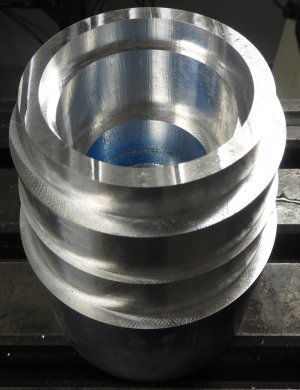

This operation entailed using a band saw to begin with. I am strongly thinking about employing it on setup 1 also to keep the solids.

Next I finished the pockets .

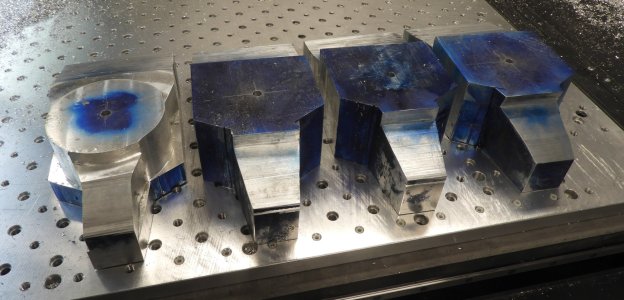

Rough, finish.... etc... This is going to change on V3 to rmove time.... I found that roughing on the router is wayyyyy faster. I can feed 1/8 deep 0.4 wide with a 3/4 endmill at 60 inch / minute... not to mention the 400 IPM rapid.

Also note my social distancing screens. These add a layer between me and a shattering 6000 RPM carbide endmill. It also keeps the chips better contained. These can still be bought, for a short while, since Covid is mostly over...

This is done on a fixture. I am thinking about re-investing my pay form this job into 4 more billets and 1 new fixture plate that will cut 2 at once....

Anyway here is the almost finished product. I have side, end, and other holes to go in. Toughest will be the 6 deep 0.500 ream. I am thinking about getting my friend with real CNC's to help me out on the deep drilling....

This operation entailed using a band saw to begin with. I am strongly thinking about employing it on setup 1 also to keep the solids.

Next I finished the pockets .

Rough, finish.... etc... This is going to change on V3 to rmove time.... I found that roughing on the router is wayyyyy faster. I can feed 1/8 deep 0.4 wide with a 3/4 endmill at 60 inch / minute... not to mention the 400 IPM rapid.

Also note my social distancing screens. These add a layer between me and a shattering 6000 RPM carbide endmill. It also keeps the chips better contained. These can still be bought, for a short while, since Covid is mostly over...