-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alexander Deckel SO Clone

- Thread starter Susquatch

- Start date

POR 15 make great products, the closest thing I have found to powder coating for durability, The drawbacks to POR 15 are the smell, time to cure and the stuff will not clean off your skin!

Powder is still the toughest coating I have ever used, mostly for vintage motorcycle frame and related components. I have restored one motorcycle frame using POR 15 but it does not turn out as nice as powder coating.

I have an old wall oven in a home made square steel tube frame, I am limited to what fits in the cabinet, larger parts I farm out to the pros.

DIY powder is very easy, no smells, most powder cures in 20 minutes between 350 ~ 400 F, once the part cools down its good to go and powder only comes off with a razor blade or a very special powder coat solvent. I have used the same Eastwood Automotive powder gun for over ten years, you only need to run about 3 ~ 5 psi air pressure and find an old oven. I have keep about 20 colors / finishes in my little inventory. Last year I completely stripped down my Atlas 7B shaper and powder coated every part in my wall oven.

I have a vapour blast cabinet but any dry blast cabinet will suffice, use fine glass bead, wash and then wipe down with Acetone before spraying the powder on.

It takes me less than hour to clean, blast, wash, spray the powder, bake the part and clean up the small amount of dry powder overspray. The part is fully cured after twenty minutes in the oven and then as soon as it cools down its finished, no smell, no runs or drips, and its many times stronger than any other form of paint. I will never go back to rattle cans or even automotive spray products.

Powder is still the toughest coating I have ever used, mostly for vintage motorcycle frame and related components. I have restored one motorcycle frame using POR 15 but it does not turn out as nice as powder coating.

I have an old wall oven in a home made square steel tube frame, I am limited to what fits in the cabinet, larger parts I farm out to the pros.

DIY powder is very easy, no smells, most powder cures in 20 minutes between 350 ~ 400 F, once the part cools down its good to go and powder only comes off with a razor blade or a very special powder coat solvent. I have used the same Eastwood Automotive powder gun for over ten years, you only need to run about 3 ~ 5 psi air pressure and find an old oven. I have keep about 20 colors / finishes in my little inventory. Last year I completely stripped down my Atlas 7B shaper and powder coated every part in my wall oven.

I have a vapour blast cabinet but any dry blast cabinet will suffice, use fine glass bead, wash and then wipe down with Acetone before spraying the powder on.

It takes me less than hour to clean, blast, wash, spray the powder, bake the part and clean up the small amount of dry powder overspray. The part is fully cured after twenty minutes in the oven and then as soon as it cools down its finished, no smell, no runs or drips, and its many times stronger than any other form of paint. I will never go back to rattle cans or even automotive spray products.

gerritv

Gerrit

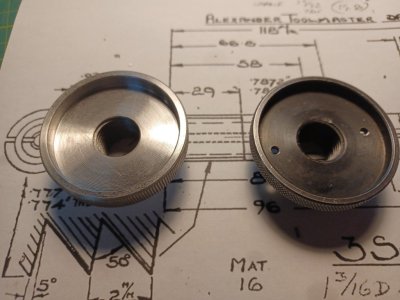

Done, a replacement for the missing locking collar. New on the left, my original on the right. The new one has straight knurling, I think it is grippier, tempted to give you my original 🙂

@Susquatch Question, do you want it blackened or left natural? I suspect this is W1 given how it cut. End of material was painted yellow.

@Susquatch Question, do you want it blackened or left natural? I suspect this is W1 given how it cut. End of material was painted yellow.

Attachments

The new one has straight knurling, I think it is grippier, tempted to give you my original 🙂

You keep whichever one you like best. I'm just happy to have something that works!

@Susquatch Question, do you want it blackened or left natural?

Blackened is best for my needs. But if it makes your life easier I am happy with left natural.

I'm making very very slow progress with sanding the main body. I don't need much excuse at all to get distracted. I HATE PAINTING and EVERYTHING to do with painting.

Question for you @gerritv, there are two fittings on the main body feeding the spindle. A grease fitting and some kind of lock-nut assembly. The drawings and manuals only show one. Why do think that there are two on mine?

The picture is an old one before I started sanding. But that's all I had on my phone.

I've removed and plugged them to sand around them. But I'd like to know what you think they are for. The zirc seems to have relatively heavy grease in the hole. The screw cap is empty under it. Thoughts?

gerritv

Gerrit

yes, Rocketronics ELS ProDo I see an ELS?

gerritv

Gerrit

this thread has a bunch of info, https://canadianhobbymetalworkers.com/threads/king-kc1022-rocketronics-els-pro-installation.14990Rocketronics ELS! project 43 for me sigh...Let's see more @gerritv ! 😎

If you want videos of it in use let me know.

gerritv

Gerrit

The screw holds the spindle cartridge in place.Question for you @gerritv, there are two fittings on the main body feeding the spindle. A grease fitting and some kind of lock-nut assembly. The drawings and manuals only show one. Why do think that there are two on mine?

I've removed and plugged them to sand around them. But I'd like to know what you think they are for. The zirc seems to have relatively heavy grease in the hole. The screw cap is empty under it. Thoughts?

The screw holds the spindle cartridge in place.

Thanks Gerrit. Seems rather odd that it isn't shown on the parts diagrams. But stranger things happen all the time!

If you want videos of it in use let me know.

Letting you know. YES!

Guess what arrived today?

The collet nut and indexer @gerritv made for me that my grinder was missing. They are drop dead beautiful! LOVE the cut knurling on the collet nut! I need to move that tooling up the project priority list.

Gerrit is a total trouble making enabler though! He also included a collet holder he made for me on his 3D printer....... Oh my...... That little gem is gunna cost me big time....... Totally infectious! I think I'm running a 3D Fever already.....

Yup, I gotta up my Fusion 360 game and buy a nice 3D Printer so I can do that too! It just got moved waaaay up my priority list!

Big thank you to @gerritv! Didn't have to make that stuff for me. I didn't even ask him. He just did it out of the goodness of his heart. I'm VERY GRATEFUL!

The collet nut and indexer @gerritv made for me that my grinder was missing. They are drop dead beautiful! LOVE the cut knurling on the collet nut! I need to move that tooling up the project priority list.

Gerrit is a total trouble making enabler though! He also included a collet holder he made for me on his 3D printer....... Oh my...... That little gem is gunna cost me big time....... Totally infectious! I think I'm running a 3D Fever already.....

Yup, I gotta up my Fusion 360 game and buy a nice 3D Printer so I can do that too! It just got moved waaaay up my priority list!

Big thank you to @gerritv! Didn't have to make that stuff for me. I didn't even ask him. He just did it out of the goodness of his heart. I'm VERY GRATEFUL!

I hope the locking handle was there as well?

I didn't see it. I still have the box and packing. Let me look, again.

Edit - Yup! It was buried in the bubble pack! Now that is a gem! I will have to try that method for sure! Nice touch with the brass tip on the screw! I think there is one in the bottom of the hole too cuz the dimension doesn't add up.

IMO I did have to make those items for you given that I got you to buy the grinder. Without those items it wouldn't be much use and you have enough to do just getting it painted. 🙂

You and I share common ethics. But I didn't hold you responsible for that. I just REALLY APPRECIATE what you did for me with no strings.

And yes, I really do hate painting...... It's a painful slow process but should be nice when done.

Hmmm no pics? I’m calling BS!

Wow. Tough crowd!

Here is the main body being sanded. I'm just taking it down enough to make it smooth and get rid of the paint sags and damage.

And this is all the tool holder gimbal parts. I stripped them all right down because they had paint where it didn't belong. The parts circled in yellow are the ones @gerritv made for me.

And here is that infectious collet holder......

Are you happy now?

140mower

Don

You know the rules..... 🙄 😉 😛Wow. Tough crowd!

Here is the main body being sanded. I'm just taking it down enough to make it smooth and get rid of the paint sags and damage.

View attachment 69547

And this is all the tool holder gimbal parts. I stripped them all right down because they had paint where it didn't belong. The parts circled in yellow are the ones @gerritv made for me.

View attachment 69548

And here is that infectious collet holder......

View attachment 69549

Are you happy now?