I've been eyeing this VRT shop 100% bolt together design. Of course there are some things I might do a bit different but I suspect all these grinders inevitably get a personal touch in some manner, or have to be modified on basis of motor selection, space limits, whatever. Of course if you have a welder there are lots of places where it would be beneficial, so use it. But I'm trying to visualize issues where a bolt together would not be satisfactory. Maybe my brain just wants to see if an IKEA 1-hex wrench design is possible haha.

description on Etsy here

https://www.etsy.com/ca/listing/1801679329/2x72-tilting-belt-grinder-metric-plans?click_key=9c39407d9dbe3bc464942832bcc0660d648ddbbc:1801679329&click_sum=9b93f35e&external=1&rec_type=cs&ref=landingpage_similar_listing_top-8&sts=1

YouTube channel elaboration here

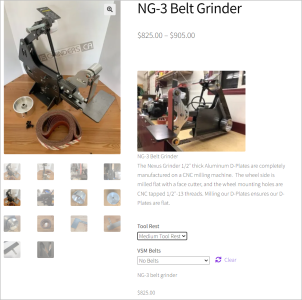

Where is the best place to buy belt wheel components (for a Canuck)? Seems like those are items not worth self-fabricating unless you had a real custom design. Nexus has parts but maybe more orientated to his own kit? Seems like good one stop shopping for belt grinder supplies but some of the drive components & electrics seem spendy (although I havent really sat down to compare).

nexusgrinders.ca

nexusgrinders.ca

description on Etsy here

https://www.etsy.com/ca/listing/1801679329/2x72-tilting-belt-grinder-metric-plans?click_key=9c39407d9dbe3bc464942832bcc0660d648ddbbc:1801679329&click_sum=9b93f35e&external=1&rec_type=cs&ref=landingpage_similar_listing_top-8&sts=1

YouTube channel elaboration here

Where is the best place to buy belt wheel components (for a Canuck)? Seems like those are items not worth self-fabricating unless you had a real custom design. Nexus has parts but maybe more orientated to his own kit? Seems like good one stop shopping for belt grinder supplies but some of the drive components & electrics seem spendy (although I havent really sat down to compare).

Nexus Grinders And Knife Supply

We carry Stainless Steel, High Carbon Steel and Tool Steel for Knife making. We also have G10 liners, handle material, and hardware. We sell 2x72 Belt Grinders that are well designed, practical and rugged. Our 3 arm grinders are one of the most affordable chassis on the Canadian market.

nexusgrinders.ca

nexusgrinders.ca