Matt-Aburg

Ultra Member

I will give a written quote with a purchase order that must be signed before starting. All expectation must be in writing. For example, he changed the tolerance expectations from 1/16 to 1/32. Delivery time and dollars all agreed to up front. In mold industry, they require 1/3 down, 1/3 at first tryout and 1/3 after shipping. Chinese toolmakers withhold the tool until paid in full.For new clients I typically used letter of intent to purchase services... It was the foundation we built relationship on. It eliminated most uncertainties and set expectations.

But most importantly, the letter of intent made it clear, NO WORK PRODUCT DELIVERED WITHOUT PAYMENT IN FULL UPON DELIVERY.

and in most cases that meant payment via credit card

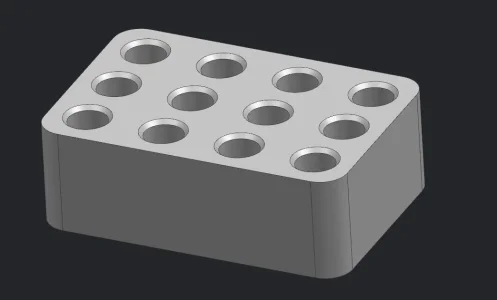

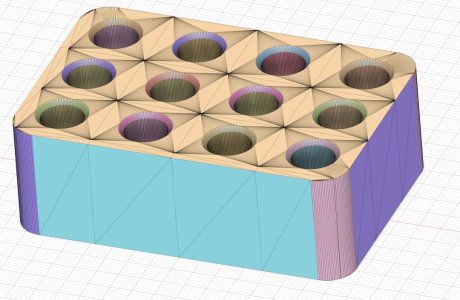

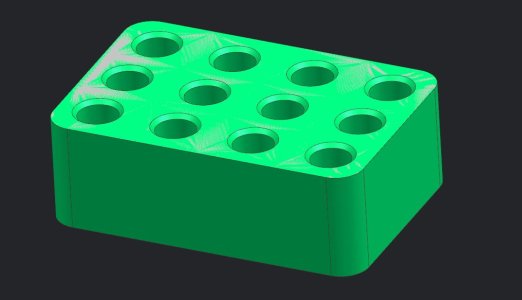

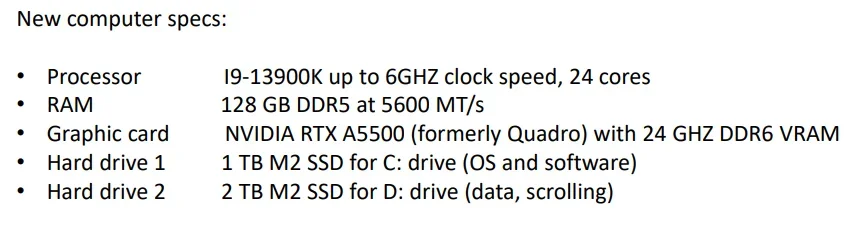

For me, I will show pictures, make PowerPoints, have meetings. but no data until paid in full. I have known this person since 1992. He was my boss for almost 10 years. Now he is retired from molds as am I. There is great potential. I have already invested in the equipment and it is paid for. I need to find the proper software. He does not want 20K software that I know... I think the Autodesk product. or a combination of different software's, (one for design, and one for CNC). I also own a seat of Mastercam Mill level 1, so can provide programming services legitimately.

When the PowerPoint is ready, we will have to have a meeting to discuss all aspects of the work or job opportunity.

Last edited: