Bill Perkins

Member

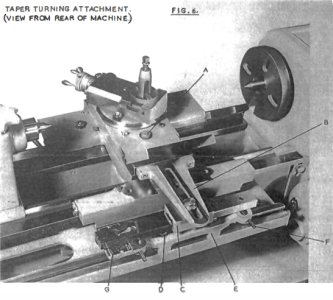

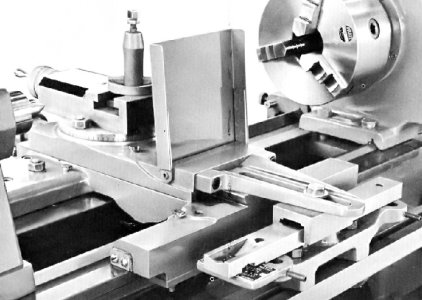

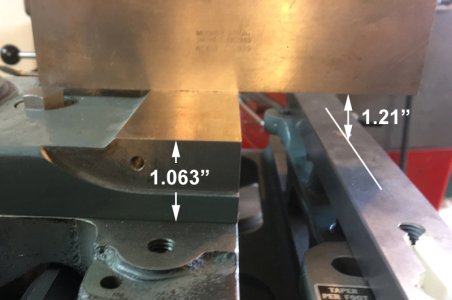

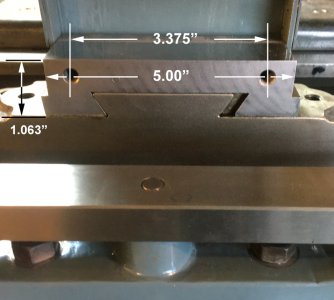

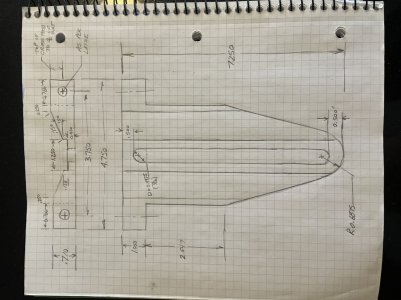

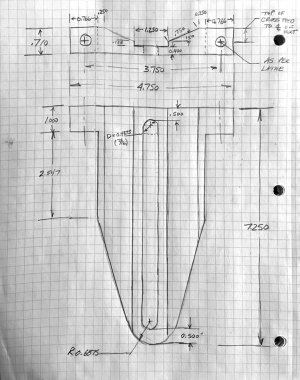

I'm completely off-thread here and wonder if you worked up a drawing for the "cross slide puller" that the taper attachment on a D1-3 11 x 20 Utilathe uses. As seen in the pic, you made the actual part for your 10" machine and I think you mentioned planning to do drawings for the 11" and 12" versions.

I don't know to take a subject off list w/o splashing an e-mail address in front of a billion spammers so if you could contact me I'd appreciate it.

Thx,

Bill @ PEARL, Inc

I don't know to take a subject off list w/o splashing an e-mail address in front of a billion spammers so if you could contact me I'd appreciate it.

Thx,

Bill @ PEARL, Inc