I've butchered a couple of back plates 'teaching' myself lessons so far.

Hey Kevin.... where did you get the back plates from?

Craig

I've butchered a couple of back plates 'teaching' myself lessons so far.

Hey Kevin.... where did you get the back plates from?

Craig

Are they threaded or on backplates?

Sent from my iPhone using Tapatalk

Sorry I was unclear, my fault.

I was meaning the new chucks.

Sent from my iPhone using Tapatalk

Looks good Tom. Does that plate have a tapered center bore that mates the spindle nose?

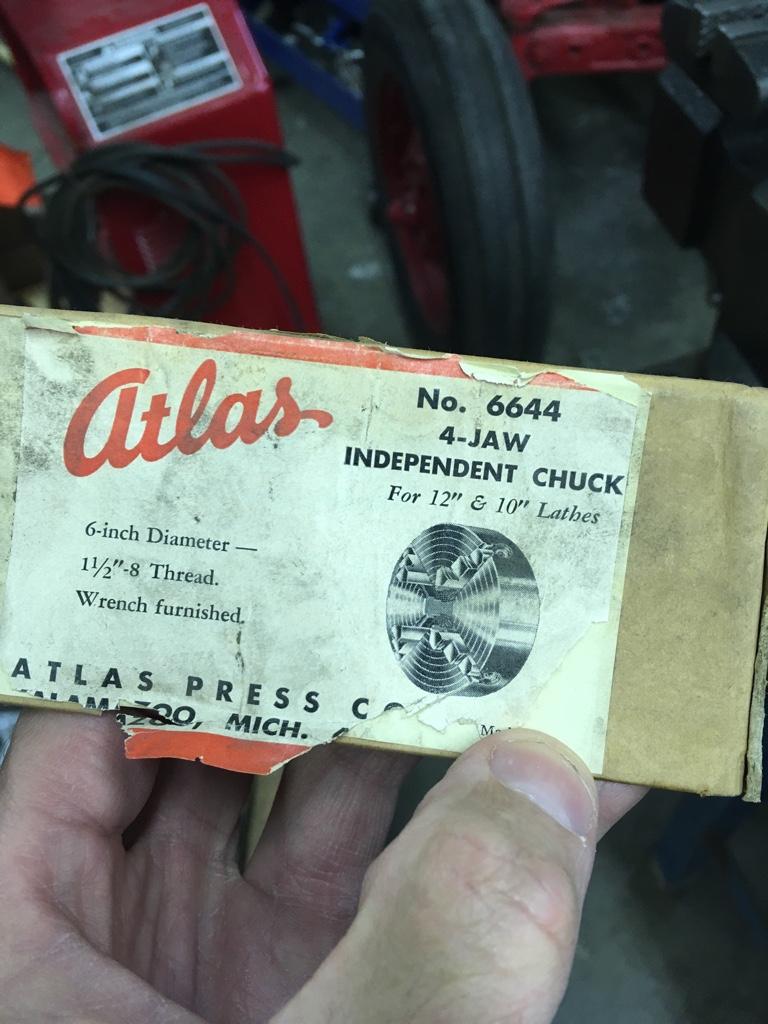

can someone post a picture of the 4 jaw they got? Can it be machined to be a plain back? How about 3 jaw?