Sure Peter. I'll just drink the coolaide and everything will be ok.

Can you do me (us) a favour? In 6 paragraphs and preferably MUCH less, can you explain what G-Code is?

Same for Slice Code.

Same for STL Code.

It all doesn't sound very plug'n'play or user friendly to me.

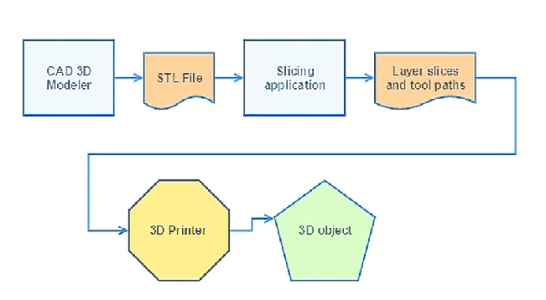

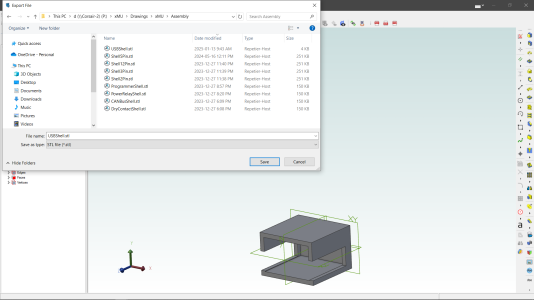

"STL code" doesn't exist/is not a term. An STL is the file format/extension of your 3d model. ".STL". Almost every CAD program out there can save a model as an .stl file. That's it, that's the extent of the knowledge you need to know about that.

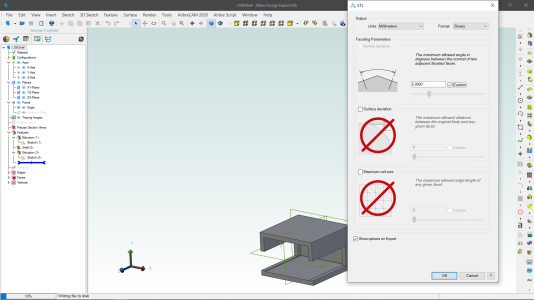

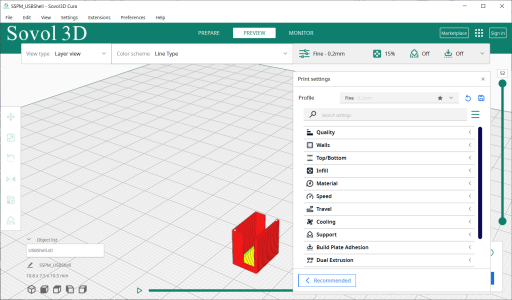

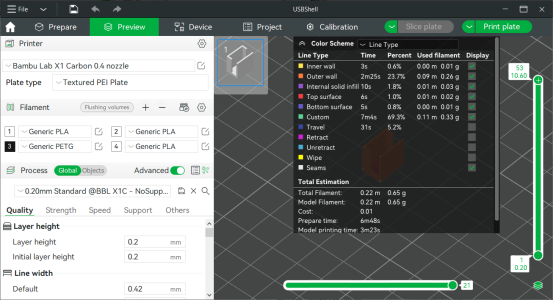

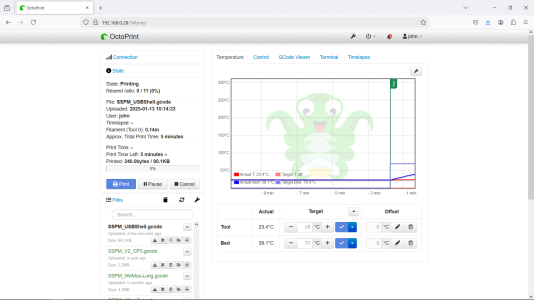

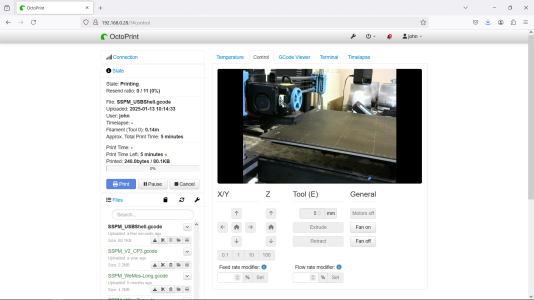

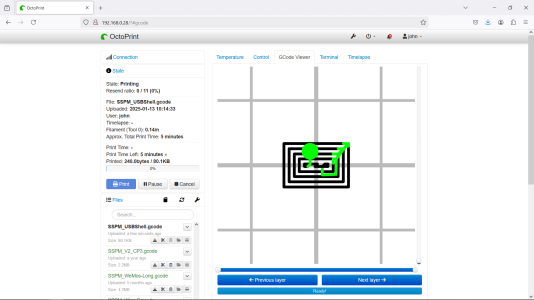

"slice code" doesn't exist/is not a term. "Slicing parameters" would perhaps be a better more accurate term. A "slicer" is the software program (cura, Bambulab, etc) you load your 3d model (stl file) into. It's job is to take the parameters you specify such as infill density, perimeter lines (shell thickness), layer height, print temp, bed temp, etc and generate the "G code" that the printer then uses to drive itself. Don't be alarmed about all the parameters. Most are simply default based on your material selection, and you can get as in depth, and hands off with those as you like. Have a part that needs to be strong? make it a denser infill, with a thicker wall/shell etc....You can use slider bars to change these parameters (or input text), and see a visual representation of your printed part change in real time on the screen.

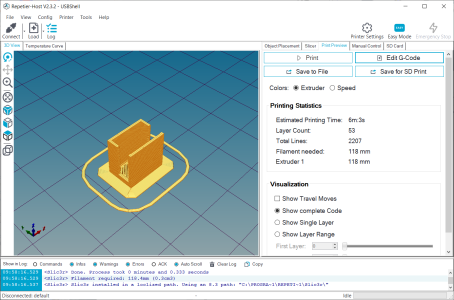

"G Code" is the language of code that the printer (and almost ALL CNC machines) uses to drive itself to the specified coordinates in order to print your part. If you understand the Cartesian coordinate system (I am assuming you do based on your engineering background...) , all g code is, is essentially a simple text file of instructions telling the machine where to go, how fast to do it, and what to do when it get's there. That basically it. For the 3d printer interface and workflow, you don't even touch/look at the gcode, or even need to know what any of it means. The slicer handles ALL of it. I'd probably throw out a guess that over 90% of the worldwide printing community couldn't read a line of Gcode and tell you what it means. It's knowledge thats simply not needed to print parts. Aside from my initial curiosity, I can't tell you the last time I actually looked at the gcode for a print file let alone edited it.

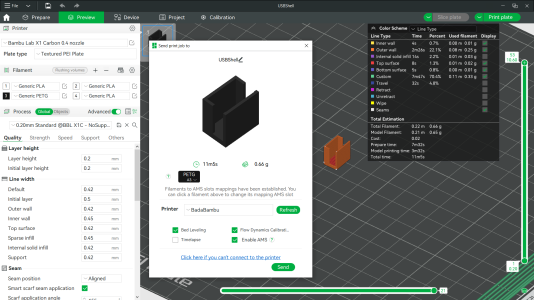

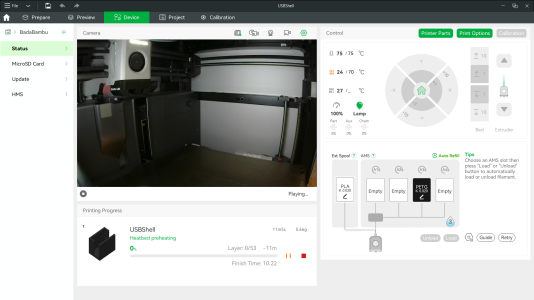

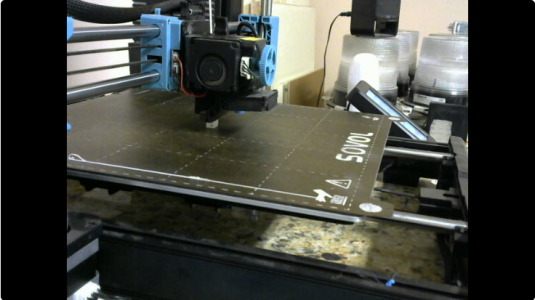

I made a living programming CNC machines in part for about 20 years. Using a variety of software from mid/high end CAM packages, to notepad, or simply punching it in at the control. "programming" a 3d printer is about as simple an operation as there is. It really bears zero resemblance to industrial CNC programming, and absolutely ZERO prerequisite knowledge of Gcode, or other programming language is required. The slicer handles all the Gcode production based on the slicing parameters you select, and creates the file in the background in real time. All you have to do is save it to a memory stick, insert it into the printer, then select it from a list and hit go (wifi connectivity even bypass' that step). Slicing a 3d model to print really couldn't be any simpler. IMO the 3d printer community has done an absolutely fantabulous job of streamlining the entire workflow, and to be honest, if they ever got a hold of the industrial side I would have been out of a job years ago lol. If there is an Ontario get together this year, I will bring mine, and my laptop and give a demo.

That all being said, generating the models to print in CAD can absolutely be a challenging process for some, but that's the same as it is for machining. The difference being you can actually print stuff that you couldn't physically machine. Cad is another can of worms altogether, but there are some very simple programs out there like tinker cad. My kids 10/12 are starting to pick that up. It's pretty basic, but it's capable of creating models to print, and saving as an .Stl.

6 paragraphs...phew....Hopfully adressed your questions. I tried to be direct and concise. Not easy for me, as I tend to get ranty, rambly, and wordy trying to make a point sometimes......

😀. You should see all the stuff I cut out.......Cheers!