-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WTB - Tapping Head

- Thread starter YYCHM

- Start date

Just use a tapping chuck like I do on the lathe - easy to use, have all cool functionality EXCEPT auto reversing. Just simply run lathe or mill in reverse and presto you can do a lot and lot of tapping.

What exactly does a tapping chuck accomplish?

Tom Kitta

Ultra Member

What exactly does a tapping chuck accomplish?

It has a square drive catch - i.e. catches the tap by the square end so it does not slip. Good enough for larger taps.

For small stuff you can just guide a tap wrench in - like sensitive drilling - sensitive tapping.

It has a square drive catch - i.e. catches the tap by the square end so it does not slip. Good enough for larger taps.

For small stuff you can just guide a tap wrench in - like sensitive drilling - sensitive tapping.

Does it have a clutch to prevent breaking taps?

little ol' e

Jus' a hobby guy

I realize this post is dated several weeks old now.

Just a thought here

Have you checked out the flex arm tapping units or other cheaper brands?

They work great IMO, clutch type tap holders to prevent breaking taps. Easy to set up and a breeze to use. Quicker than tapping on the machine, especially if you have several different sized tapped holes to do in each part.

They vary in pricing, but the small units capable of tapping up to 1/2" are reasonably priced.

Just a thought here

Have you checked out the flex arm tapping units or other cheaper brands?

They work great IMO, clutch type tap holders to prevent breaking taps. Easy to set up and a breeze to use. Quicker than tapping on the machine, especially if you have several different sized tapped holes to do in each part.

They vary in pricing, but the small units capable of tapping up to 1/2" are reasonably priced.

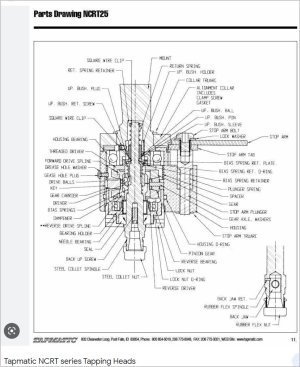

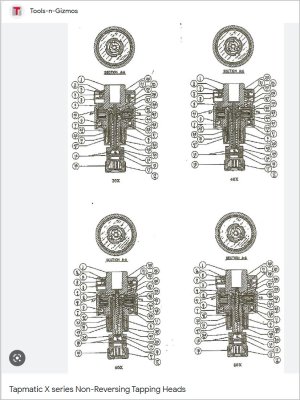

Attachments

oh? I looked at some when ABOM got his but they were all north of 4K$US..but the small units capable of tapping up to 1/2" are reasonably priced.

little ol' e

Jus' a hobby guy

oh? I looked at some when ABOM got his but they were all north of 4K$US..

Depending on the model and accessories added, they can get up in price.

Alincochrane

Member

Craig, I have a Procunier model 2E I don't need. It takes #6 - 1/2" and has a #2 MT shank. PM me a.bays (at) flare-consultants.com for more info.

Ideally it would....

Have an adjustable clutch system

Tap up to 1/2"

Have R8 or 3/4" straight shank

Be auto reversing

I'll consider anything actually...

PM me if you have something to part with.

Thanks,

Craig

Any one ever come across plans for building a tapping head?

Did you ever find a tapping head?Ideally it would....

Have an adjustable clutch system

Tap up to 1/2"

Have R8 or 3/4" straight shank

Be auto reversing

I'll consider anything actually...

PM me if you have something to part with.

Thanks,

Craig

I have 2. One mounts the housing on the spindle of my Jet drill press. the chuck is removed and the moving part of the head couples to the Jacobs taper. No bars are needed to stop rotation of the housing.

The other has a MT 2 spindle and a bar to stop the rotation

Both are auto reversing-I can check the specs and manufacturers if you like

John

Did you ever find a tapping head?

I have 2. One mounts the housing on the spindle of my Jet drill press. the chuck is removed and the moving part of the head couples to the Jacobs taper. No bars are needed to stop rotation of the housing.

The other has a MT 2 spindle and a bar to stop the rotation

Both are auto reversing-I can check the specs and manufacturers if you like

John

PM Sent.