I have been super busy, but got a chance in the past couple of days to make some progress on both my TIG welding and my plasma cutting testing.

I had previously put together a 25 foot 3/8 inch air hose with quick disconnects to connect my 300 cu ft Nitrogen cylinder to my BestArc lunchbox size plasma cutter. Then I put together a pressure gauge / regulator "module" that can be inserted between the air hose and the BestArc:

I used Loctite 565 to seal all the joints, and soapy water bubble testing produced no bubbles!

This Nitorrgen + airline + psi regulator setup enables me to get 125 psi to the input of the BestArc, but to then reduce the psi INSIDE the BestArc down to 70 psi or a lower pressure, so that the inside air conncctions in the BestArc don't get overpressured.

So, now I have very controllable psi into the BesArc.

I also bought some 1/8" thick aluminum, as I had previously had only 3/16" aluminum to use in my testing, and I am veyr glad I got the 1/8".

I have now found that even with well controlled Nitrogen pressure, with basically unlimited CFM available, the BestArc still does a marginal job of cutting 3/16" aluminum, even when I crank the internal Nitrogen psi to 70 and the amps to 45 (I have only a 50 amp supply to my garage workshop, and need a bit of that for lighting).

All the plasma cutter experts tell us that for any given plasma cutter capacity, the capability to cut aluminum versus steel is only about 2/3 of the capability to cut steel. The little BestArc is rated to cut up to 1/2" steel, BUT I think that may be a stretch for this little guy. If it could really do that well, it should be able to cut maybe 2/3 x 1/2" = 1/3" = .333". But, I have found that while it will cut the 3/16" = .19" thick aluminum, it ain't pretty at all.

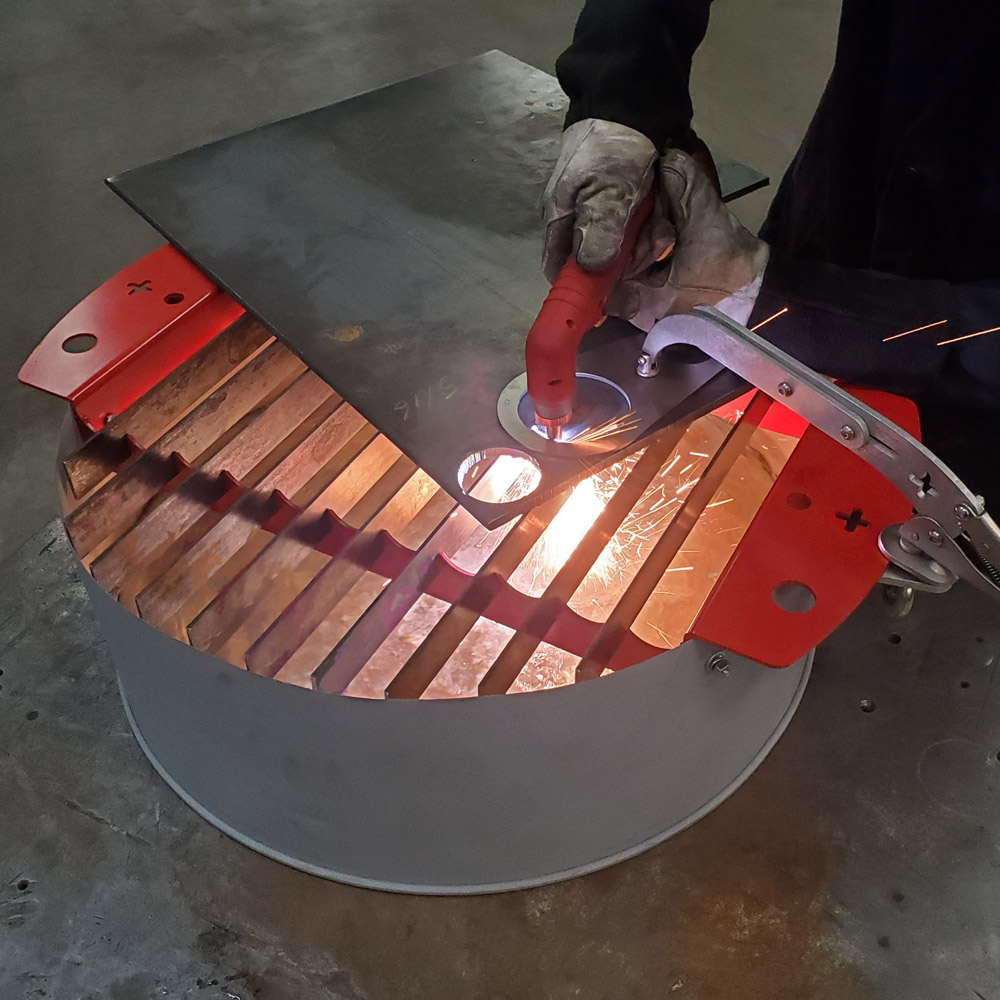

The little guy does much better on 1/8" aluminum when I use 70 psi and 43 amps:

Note that the angle of the cut marks is just about perfect, the slag on top is minimal, and the slag on the bottom is relatively sparse and easily ground or sanded off.

And curved cuts are good too:

Notice that the top of the cut is pretty much slag-free, and the bottom is pretty minimized too.

The angle of the cut lines is not as good as for the straight cut, but that was me, not the machine, as I did not regulate my speed of movement as well on the curved cut.

Both were done very quickly too, and therefore used up far less of the Nitrogen than the amount of air I used when trying to do this with my undersized air compressor. I experimented by cutting the afterflow of the Nitrogen down to just 6 seconds, without any adverse effect. I figured on there short (2") cuts, the cutting head would not get very hot and the shorter afterflow should be fine. So far so good.

Since the majority of my anticipated plasma cutting will be on 1/16 to 1/8" thick aluminum or stainless steel, this setup should work for me. I would have liked for 3/16" aluminum cutting to be better than it appears to be right now with this machine, but it WILL make those cuts too, just not as cleanly.

That Loctite 565 really seems to work on keeping the air (actually Nitrogen) lines from leaking. I tested my entire Nitrogen feed system from cylinder to that final psi regulator / gauge just before the QD that connects to the BestArc, by leaving the cylinder valve closed and the entire air line hose assembly regulated to 125 psi. 5 hours later there had been ZERO pressure drop.

It remains to be seen how much Nitrogen I will actually use with this setup and my rather low plasma cutting needs, but I will report in the future my actual experiences with that.

Jim G