Knock on wood, it would appear that I am done lighting money on fire with my Tormach...... for now.....Long story short, Back in July my X axis stepper

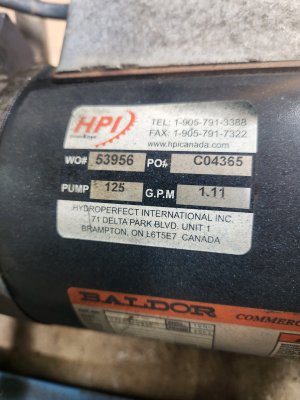

shit the bed. I ended up buying a set of steppers from a guy on market place that had upgraded to servos. I bench tested the motor and everything worked great. When hooking up the new motor after running the wires through the Tormach conduit I ended up shorting it out because one of the wires got pushed back inside the end bell and got caught on the shaft tearing it up. In hindsight, I "should" have caught it, but it's not something I honestly thought to look for. Good thing I bought 3.....I could have swore I typed out a reply about it in that thread? but guess I was too pissed off at myself to do so. Maybe I didn't hit send. Oh well....

I opened up the driver and had a quick poke around hoping for something obvious and spotted a blown fuse. Not seeing anything else visually fried, but lacking the equipment and testing knowledge to dive further I ordered some from ali and waited for what seemed like forever. After it finally got here 2 weeks ago I soldered it in, and hoped that the fuse was all that was wrong. Still dead, It must have blown something else.

Dejected, but seemingly made of money at this point, I broke down and ordered a new one from Tormach after weighing my options of used ones from ebay, or trying to get a cheaper generic leadshine one to work with some modifications. We were away on a working vacation to PEI last week when it arrived, and tonight was my first chance to get back to this after getting back late monday night after a 16.5 hour drive. I was pretty damn happy to see that Green light again

😀

My original conduit was split in a few places, and while I did initially fix it jankily after getting the new motor so I could get it up and running quick for a job at the time (which I ended up having to scramble to find someone else to cut for me after blowing the driver), I decided I should come up with something better now that I had some downtime. I wasn't a fan of Tormach's choice of materials here, which is why I didn't just order a replacement with the driver. I'm still on the fence about my solution too. Not sure it's a good one yet, but it's a pretty cheap/cost effective one for now, and I think it'll work just fine......Water tight, flexible......let me know your opinions. Good or bad. I might stick a stainless braid over it for abrasion resistance, or at least a strain releif, but will test it out for a while and keep an eye on how it's holding up. I don't expect a super long life if I was running this every day.

The motor end is a 1/4" npt push to connect for 1/2" tube. The column end is an m18 ( I think?). I made an adaptor out of a pg-11 plastic gland nut cutoff and tapped internally for 1/4" nptf. I had to shorten the motor end so as not to short out against the windings again (fool me once....

😀) and bored them out bigger to pass the wires through. No pics taken of that, as to be 100% honest, I'm pretty emotionally done with this "project/adventure" right now.....

I was originally going to run the motor wires into a waterproof splice box fastened to the side of the motor and from there run cabtire into the control panel, but changed my mind after the boxes arrived and went with this. More money spent......More time wasted......

I also had to lengthen the wires from the stepper about 14" to reach the driver (one reason I was leaning towards the splice box), but when I plugged everything back in, and flipped the switch everything came back to life as it should. Finally. Ran it through a couple of old programs and it's all good and everything appears fine again. The conduit works fine at all extremes of travel.

Tomorrow I have the entire day to myself to clean it up and put all back together, get the coolant tank cleaned up with a fresh batch mixed up, and hopefully. Hopefully, make some chips finally. See if I actually remember how to run one of these things, it's been a while.....