Dan Dubeau

Ultra Member

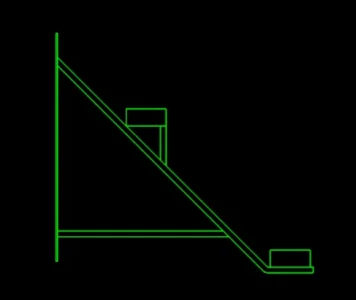

This was fun. I've never capped round like this, and wanted to try it before I cut the excess off the bent railing.

Simple folded paper template to mark out the quadrants and length. No math, and a free handed curve.

Some portaband/cutoff work.

Some hammer work. Little by little, closed the gap pretty good. Tried a little heat at the end just because I wanted to see if I could bring edges in a tiny bit more but not really worth the effort to IMO. Diminishing returns

Some welding, and grinding....

I think it came out great, so I sliced the handrails to length, and did this to all four ends.

It's been an interesting week....Nice to be back in the shop.

Simple folded paper template to mark out the quadrants and length. No math, and a free handed curve.

Some portaband/cutoff work.

Some hammer work. Little by little, closed the gap pretty good. Tried a little heat at the end just because I wanted to see if I could bring edges in a tiny bit more but not really worth the effort to IMO. Diminishing returns

Some welding, and grinding....

I think it came out great, so I sliced the handrails to length, and did this to all four ends.

It's been an interesting week....Nice to be back in the shop.