JReimer

Well-Known Member

Hi,

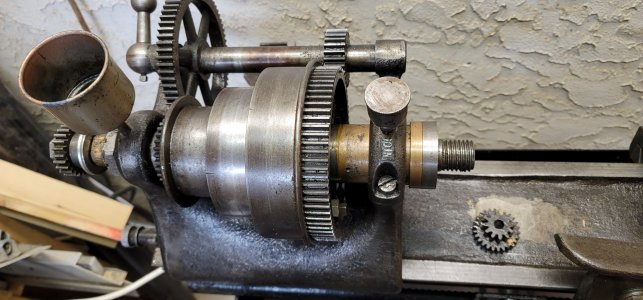

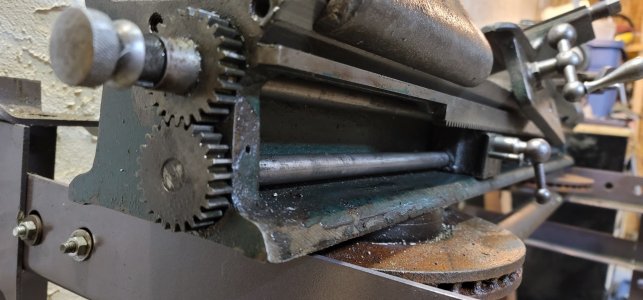

I am returning / new to metal work and recently found a good deal on a vintage metal lathe that I want to restore and start using. It was working for the guy who sold it to me but he had taken it all apart for transport. I want to restore the lathe and do some much needed maintenance. The lathe doesn't have any makers mark and wondering if anyone can help me identify what lathe this is and if there are any schematics, manuals out there for missing parts or optional extras.

It's a really cool old lathe and excited to get it back into prime condition.

Thanks

I am returning / new to metal work and recently found a good deal on a vintage metal lathe that I want to restore and start using. It was working for the guy who sold it to me but he had taken it all apart for transport. I want to restore the lathe and do some much needed maintenance. The lathe doesn't have any makers mark and wondering if anyone can help me identify what lathe this is and if there are any schematics, manuals out there for missing parts or optional extras.

It's a really cool old lathe and excited to get it back into prime condition.

Thanks

Attachments

-

1145.jpg600.9 KB · Views: 77

1145.jpg600.9 KB · Views: 77 -

1146.jpg612.8 KB · Views: 82

1146.jpg612.8 KB · Views: 82 -

20220223_200140.jpg489.3 KB · Views: 69

20220223_200140.jpg489.3 KB · Views: 69 -

20220223_200146.jpg446.6 KB · Views: 70

20220223_200146.jpg446.6 KB · Views: 70 -

20220223_200155.jpg349.8 KB · Views: 70

20220223_200155.jpg349.8 KB · Views: 70 -

20220223_200205.jpg363.4 KB · Views: 66

20220223_200205.jpg363.4 KB · Views: 66 -

20220223_200218.jpg214.4 KB · Views: 69

20220223_200218.jpg214.4 KB · Views: 69 -

20220223_200301.jpg468.2 KB · Views: 65

20220223_200301.jpg468.2 KB · Views: 65 -

20220223_200308.jpg400.1 KB · Views: 68

20220223_200308.jpg400.1 KB · Views: 68 -

20220223_200320.jpg270.2 KB · Views: 57

20220223_200320.jpg270.2 KB · Views: 57 -

20220223_200539.jpg452.1 KB · Views: 60

20220223_200539.jpg452.1 KB · Views: 60 -

20220223_200844.jpg386.6 KB · Views: 52

20220223_200844.jpg386.6 KB · Views: 52 -

20220223_200854.jpg302.8 KB · Views: 49

20220223_200854.jpg302.8 KB · Views: 49 -

20220223_200932.jpg226.9 KB · Views: 75

20220223_200932.jpg226.9 KB · Views: 75