-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CA-BC VFD enclosures

- Thread starter PaulL

- Start date

British Columbia

- Type

- Shop

The other place to look for enclosures is outfits that sell used industrial electrical supplies. They are not as good a deal as the ReStore but are usually half the price of new.

It's a great idea, but I can't think of such a place...... Where would you start to find one?

slow-poke

Ultra Member

We have two Re-Use type stores near us, one by the cottage and one near home. They could not be more different. The one near home is EXPENSIVE with prices on par with what you would pay new. We drop stuff there but never purchase. The one near the cottage is pure gold. Most things I purchase are priced at $1-5:

$1 spool of wire 1000' #16, picked up two spools recently, green and white.

$1 bag of 10 switches or receptacles

$1 computer type IEC line cord, I cleaned out their entire stock.

$5 per portable power tools, jigsaw, hand drill, etc

There is some incredibly nice furniture for $50-100

This place is located close to a lake (not the one we're on) that has some very expensive cottages and they get really good donations.

Place is filled with a constant stream of people at the till. I just love visiting there often. I have populated my cottage basement tool bench with a lot of tools that I would normally have to drag back and forth from home. This place is the definition of a a win-win situation, employs locals, diverts a ton of stuff from the landfill that has no place in the landfill and provides a wide selection of stuff at bargain prices.

$1 spool of wire 1000' #16, picked up two spools recently, green and white.

$1 bag of 10 switches or receptacles

$1 computer type IEC line cord, I cleaned out their entire stock.

$5 per portable power tools, jigsaw, hand drill, etc

There is some incredibly nice furniture for $50-100

This place is located close to a lake (not the one we're on) that has some very expensive cottages and they get really good donations.

Place is filled with a constant stream of people at the till. I just love visiting there often. I have populated my cottage basement tool bench with a lot of tools that I would normally have to drag back and forth from home. This place is the definition of a a win-win situation, employs locals, diverts a ton of stuff from the landfill that has no place in the landfill and provides a wide selection of stuff at bargain prices.

We have two Re-Use type stores near us, one by the cottage and one near home.

There was a delta disc and belt sander at the place here in Chatham. I steered deliberately clear of it so my wife wouldn't see me drooling. I'm guessing $50 so I'll prolly scoop it next time I go past there.

Just need a nice e-box deep enough for my vfd, a bus bar or two, a line filter, and a big shutoff switch on the side, but not a huge foot print cuz it needs to go on top of my headstock and be aesthetic. I'd like to position the VFD so I can see and access it through a hole in the lid and still have the VFD fan vent to outside the box. I see no point in a fan to vent the fan.

slow-poke

Ultra Member

That's what I did, just mounted the PC power supply fan against a cutout in the side of the $5 (A1 Electronic Surplus) alarm box. I also stuffed in the other CNC related stuff: single board PC, BOB's, and three stepper drives. Tight fit, fortunately have not had to fix or replace anything yet and it's been quite a few years. Fingers crossed.Just need a nice e-box deep enough for my vfd, a bus bar or two, a line filter, and a big shutoff switch on the side, but not a huge foot print cuz it needs to go on top of my headstock and be aesthetic. I'd like to position the VFD so I can see and access it through a hole in the lid and still have the VFD fan vent to outside the box. I see no point in a fan to vent the fan.

The VFD is actually not in an enclosure, its just mounted at about the same level as the motor at the back and off to the side on a metal plate. So far no issues, chips don't fly up there. Used armour cable for in and out.

Last edited:

At 4", are those boxes deep enough, at least for the ubiquitous amazon inexpensive ones? I've been welding 9 x 5.5 x 5.5 boxes of 11g for vfds. 3 so far and a 3D printed covers. Somewhat concerned about heat, but the AL heatsink is against the steel and so far no issues. Largish hole in the bottom for some air, but nothing elsewhere as I don't want chips getting it

Last edited:

Somewhat concerned about heat, but the AL heatsink is against the steel and so far no issues.

Boxes look Awesome. Might benefit from some connector buss bars, but that's mostly for organization. What you have is what I usually do. Sometimes after someone else looks in there I feel guilty enough to fix it.

I'd guess the trapped heat might become an issue if you started doing longer power runs at full load. But you could always monitor the temp. Do yours have an internal fan that comes on when the motor is running?

I actually like the ubiquitous VFD's. At least they come with a removeable control panel. Wish I could say the same for TECO.

I LOVE your 3D printed cover. VERY NICE!

I really like these yaskawa drives, the technical manual is over 250 pages, every parameter and fault is explained.

I couldn't find a J1000. Is that an older model? Do they have a 3HP model? Can the control panel be put elsewhere?

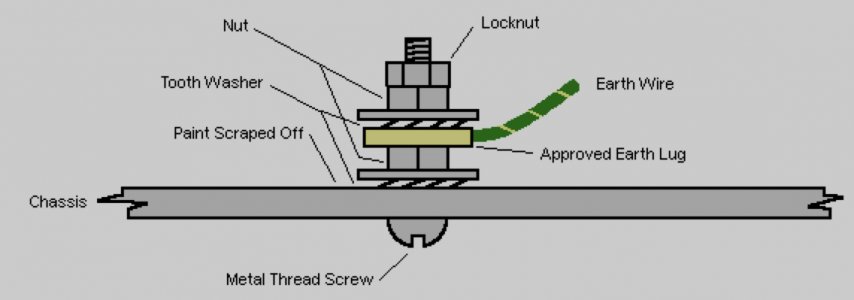

Is the green wire also connected to the box? Standard technique is a ring connector (not spade) to a bolt through the box with an unpainted area under the nut. Then the ring connectors for the Input, VFD and Output cables. Star Ground approach.

There are two marked ground wires on the input and output of the controller and are tied to the chassis and the chassis of the controller is mounted to the box I guess I could run another line to the box I am not sure its needed. That is the way they were wired there was no separate ground point on the box.

They do have bigger models I bet there would be one that would handle a motor that size. The control panel can't be moved but all the inputs you need can be remotely wired and remotely programed. These are older probably around 12-13 years but with light use. I know of many that have been on 24/7 and running about 18 hours a day for those same years with no problems.I couldn't find a J1000. Is that an older model? Do they have a 3HP model? Can the control panel be put elsewhere?

Perhaps someone with the electrical specifications can chime in here. I think the way it's supposed to be done is the AC Mains power Ground goes to the box first. Then all the other devices in the box that have a ground wire are connected to ground at that point. Often the initial input ground is locked down with another nut and then the others are on top of that locked down with a second nut.There are two marked ground wires on the input and output of the controller and are tied to the chassis and the chassis of the controller is mounted to the box I guess I could run another line to the box I am not sure its needed. That is the way they were wired there was no separate ground point on the box.

slow-poke

Ultra Member

Your description is accurate, and this is a sticky point for most ESA/CSA inspectors. IIRC the toothed washers are also mandatory, and additional ground wires must be above the nut holding the power in ground (so an additional nut required for additional ground lugs). Don't be surprised if the ESA inspector does not let it slide if any aspect of the ground bond is not as shown below. If panel is anodized instead of painted, same thing, easier to mask that area before anodizing.Perhaps someone with the electrical specifications can chime in here. I think the way it's supposed to be done is the AC Mains power Ground goes to the box first. Then all the other devices in the box that have a ground wire are connected to ground at that point. Often the initial input ground is locked down with another nut and then the others are on top of that locked down with a second nut.

Last edited:

Last night I added a cover to this project had a piece of lexan cut it down to size, some m4 screws and a piece of salvaged piano hinge and a few magnets hot glued to hold it in place, will keep the chips out and I still have quick access to change the speed which I don't do often as I thought I would I guess because of the qcgb allows me to vary the feed so easily I have gotten a good feel for what works best for the metals I like to practice on and I have learned a lot from that practice in terms of surface finish, heat, depth of cut and learning and trusting the dials and what the machine is capable of and not always pushing it I get better results. but like alot of parts of metal working the more you learn the more you understand how much more there is to these subjects and how they interconnect with each other.

I have 3 of this model. They fit the Teco VFD's that I used on my lathe and mill as well as the no-name one I used on my drill press.

I have 3 of this model. They fit the Teco VFD's that I used on my lathe and mill as well as the no-name one I used on my drill press.

I don't recall seeing that John. Can you post a few photos of the finished box with the VFD in it? Did you include a cooling fan?

I don't recall seeing that John. Can you post a few photos of the finished box with the VFD in it? Did you include a cooling fan?

Lathe VFD?

I have VFD's on both my lathes. During most operations i can leave the lathe in a fairly high gear and turn it down from there. Very handy. Good for chip control. I don't think I'd have a lathe without it...ie single phase motor.

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

Post #50

Jezz. That's even my own thread...... I am sooooo embarrassed. Getting old really sucks but that borders on dementia.

I think you and @YYCHM are great site librarians. You can find anything!

Thank you.....

Last edited: