Making my ownAre you talking about making your own power feed? Or are you trying to trick me into trying phoney CNC?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Ontario GTA West area meetup is planned for Saturday April 26th at Greasemonkeys shop in Aylmer Ontario. If you are interested and haven’t signed up yet, click here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vevor knee mill X-axis power feeds <$200

- Thread starter David

- Start date

Former Member

Guest

I choose Acorn CNC for several reasons....Here's what would be useful: some kind of controller that would allow a non-electronics whiz (aka me) to use a stepper motor, driver and power supply to drive a power feed. It's the controller part that stumps me.

I'd want to make a mount for the stepper, use a GT belts and pulleys of suitable size, and have some sort of driver/controller with a direction switch and a speed control.

Not learning new system, other than producing G-code.

Commercial base (they actually make commercial CNC's) beyond the hobby stuff.

As close to plug and play as you can get. Other than figuring out were to place limits and some stuff, its plug and play.

Simple Stuff machining use the optional remote dongle or use the built in Conversational Language and create quick programs @Susquatch.

Beyond that Teknic's Clearpath SDSK's well all I can say is steppers never, power galore.

Ok now I have some search termsplenty of off the shelf stepper programs that will simply run a stepper forward and backwards with variable speeds if you look around.

TorontoBuilder

Sapientia et Doctrina Stabilitas

check your PMsOk now I have some search terms

Now if you will allow me to throw my pitch...... Just two little words.....CNC SHAPER.........

You go first.

I don't even have a shaper yet.

what could piss away more time than that?

Are you kidding me? Let me see......

Watching corn grow?

Watching rocks grow?

Going to the bathroom?

Calculating gear ratios?

Reading the MC Catalog?

Shovelling snow in a blizzard?

Figuring out if I'm dead, or dreaming I'm dead, or just hallucinating?

Reviewing the mistakes I made in my life?

Trying to figure out if I did anything right except marry that fox I met a half century ago?

Writing this list?

140mower

Don

.....so, you are thinking about it.....You go first.

I don't even have a shaper yet.

Are you kidding me? Let me see......

Watching corn grow?

Watching rocks grow?

Going to the bathroom?

Calculating gear ratios?

Reading the MC Catalog?

Shovelling snow in a blizzard?

Figuring out if I'm dead, or dreaming I'm dead, or just hallucinating?

Reviewing the mistakes I made in my life?

Trying to figure out if I did anything right except marry that fox I met a half century ago?

Writing this list?

VicHobbyGuy

Ultra Member

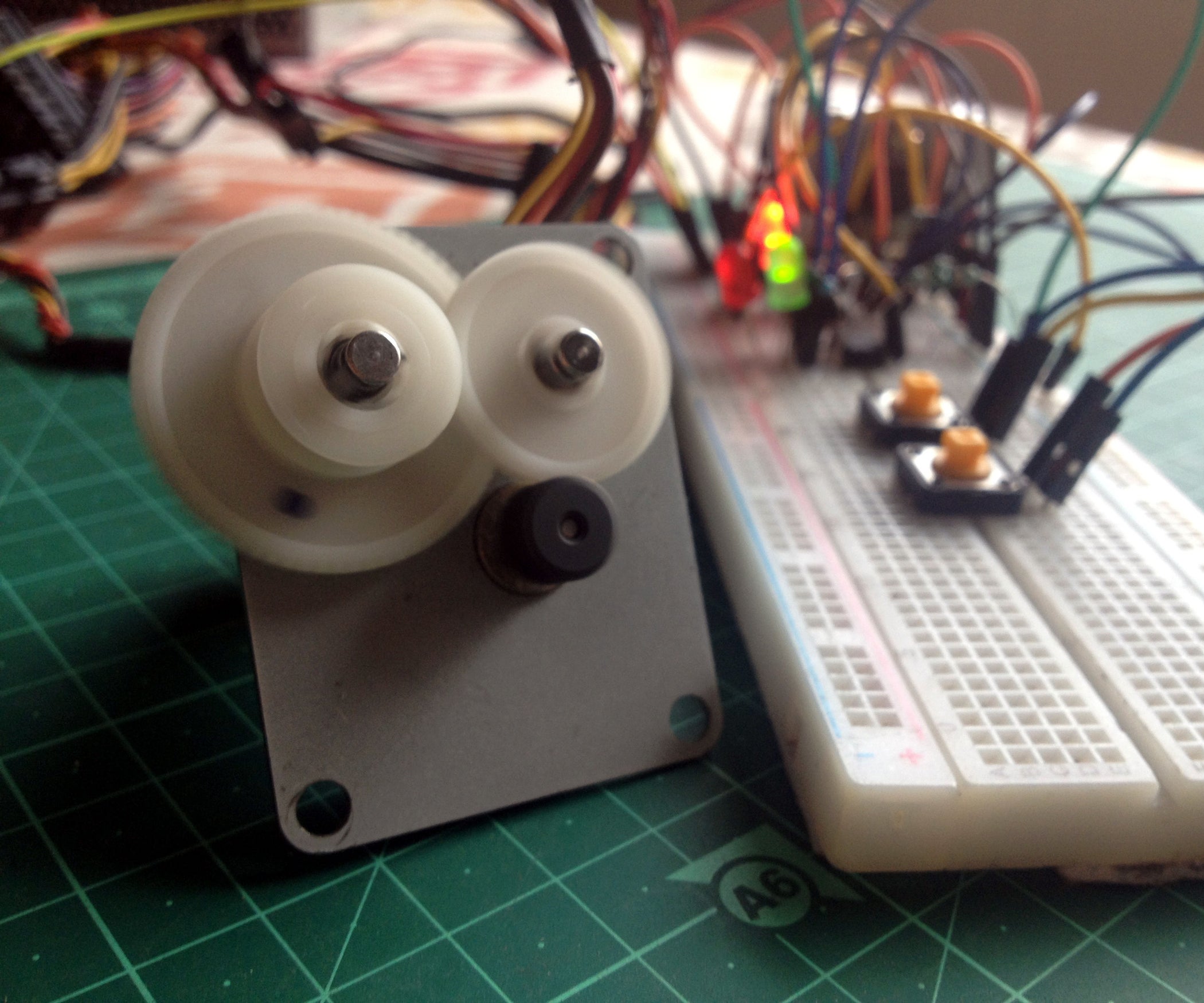

I did somehting like that for the X-feed on my Sieg X2, but that didn't need much torque. One big advantage of a stepper drive is that it doesn't require a clutch or 'engage/disengage mechanism (or belts and pulleys if you can drive the end of the leadscrew). Applying 5V to 'ENable' on the driver board makes it pretty easy to hand crank, even with the stpper motor still attached. The electronics isn't very complicated- just a bunch of switches, a pot and a basic 555 chip and a few resistors and caps on perf board - you bought a new soldering station, right?Here's what would be useful: some kind of controller that would allow a non-electronics whiz (aka me) to use a stepper motor, driver and power supply to drive a power feed. It's the controller part that stumps me.

I'd want to make a mount for the stepper, use a GT belts and pulleys of suitable size, and have some sort of driver/controller with a direction switch and a speed control.

All I need is someone to make a parts list and wiring diagramI did somehting like that for the X-feed on my Sieg X2, but that didn't need much torque. One big advantage of a stepper drive is that it doesn't require a clutch or 'engage/disengage mechanism (or belts and pulleys if you can drive the end of the leadscrew). Applying 5V to 'ENable' on the driver board makes it pretty easy to hand crank, even with the stpper motor still attached. The electronics isn't very complicated- just a bunch of switches, a pot and a basic 555 chip and a few resistors and caps on perf board - you bought a new soldering station, right?

TorontoBuilder

Sapientia et Doctrina Stabilitas

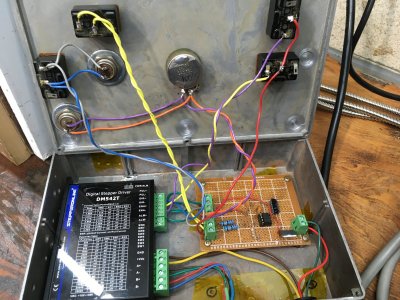

how about an entire pcb with a esp32 chip, with inputs for10k pot on board and connections for stepper driver?All I need is someone to make a parts list and wiring diagram

Im thinking about making a box

Now you're talking!how about an entire pcb with a esp32 chip, with inputs for10k pot on board and connections for stepper driver?

Im thinking about making a box

It's called an ELS from me... <GRIN> I used an older ELS on my mill knee stepper motor and Gecko drive for years.Here's what would be useful: some kind of controller that would allow a non-electronics whiz (aka me) to use a stepper motor, driver and power supply to drive a power feed. It's the controller part that stumps me.

I'd want to make a mount for the stepper, use a GT belts and pulleys of suitable size, and have some sort of driver/controller with a direction switch and a speed control.

Here's the thing. If you buy a standard COTS power feed then that is exactly what you get. If you mount a DC motor and a variable power supply of some sort that's exactly what you get.

Now, if you install some sort of stepper/servo motor that requires step/dir pulses you do need some sort of variable frequency driver for it and it has to have the ability to accelerate so that you don't either lock up the stepper motor or get what is called a servo following error. That means the step pulses arrived faster than the motor could move and the encoder feedback verses step pulses exceeded a difference between the two.

So why install something like that even though you don't want CNC? Because if you did change to CNC it's not an overwhelming change anymore. Instead it's just a module. No mechanical hardware changes.

So back to how I used my knee with the ELS. I could set the lowest point of knee movement to 0. Then just jog it up with the buttons or the MPG knob. Want another 0.010" depth of cut, just adjust it upwards by another 0.010. Want to change a tool or measure? ALT-Z_HOME and down it goes out of the way stopping automatically at that 0.000 point. Change the tool, jog back up and use the paper shim approach to find the surface for the next cut or drilling operation. I used the quill for that all those operations once it was back up because I have the Shumatech DRO-350 on the quill. Not the knee.

I'm actually amazed that the CNC ACORN type modules don't provide a "manual" operation mode. I guess it's because they are so enamored with CNC that once they go that way they question why anyone would use a mill (or lathe) manually. I use my lathe manually. I just like that it stops before it hits the jaws or bores to a fixed depth.

Like my ELS if you have a power feed on the X axis the ability to set BEGIN/END positions and then feed rate means you move to the BEGIN position. Set it. Then jog at the speed you feel comfortable with until it's just right. When the cutter clears the work piece you stop motion. Set the END position. Now Jog X up, return to BEGIN, bring Z down and move Y over half a tool diameter or whatever, and press START. Now you have power feed to an end point. The difference is you don't have to hang over the lever.

And I can say that with experience because that's what I used to do with my standard COTS power feed. Now I do the same thing with the MDI screen with feed rate set, start where I am. G01 Xnn.nn whatever nn.nn is.

Think of it this way. Crap computer shit. Much easier to use that nice clean easy to read slide rule where all the marks are laid out and you can see what the result is, to a couple of decimal places. Or forget the slide rule or the calculator. Notepad and long division is so much more reliable...

heh heh...

Here's the thing. If you buy a standard COTS power feed then that is exactly what you get. If you mount a DC motor and a variable power supply of some sort that's exactly what you get.

Excellent John. I don't want CNC, but your discussion of a better power feed is spot on.

What I like about stuff like the vevor power feed is the packaging, the controls, and single purpose hardware. It would be great if one could replace their "smoked board" with something like you describe. Of course, that assumes their hardware is all strong enough. One might need a whole upgrade kit.....

Former Member

Guest

Motor and hardware is generally fine, the board which controls the motor is a little crude, I blew a capacitor and some traces off the board when the capacitor went, the initial symptom was no speed control, followed by total shut down. Board and trace repaired and still no operation, CNC was in the works already so it just advanced the project.

If there is a step and direction board, buy a Clearpath SDSK (btw SDSK stands for Step Direction Stepper Killer) servo. Cost is higher initially, but I did mention way more power in the same size package.

This might solve your problem @Susquatch and get you one step closer to CNC. I would have going this way had I been aware of it earlier.

If there is a step and direction board, buy a Clearpath SDSK (btw SDSK stands for Step Direction Stepper Killer) servo. Cost is higher initially, but I did mention way more power in the same size package.

This might solve your problem @Susquatch and get you one step closer to CNC. I would have going this way had I been aware of it earlier.

This might solve your problem @Susquatch and get you one step closer to CNC. I would have going this way had I been aware of it earlier.

I really like @jcdammeyer approach. But I don't want separate boxes and systems. If you believe the motor and hardware are fine, then I'm maybe thinking about replacing the board with a smarter better design.

Did you pitch your power feed hardware when you canned it and went CNC? If not, I'd happily give you some coffee money for the parts......

Former Member

Guest

Yeah I ditched it as it was taking up too much space in a small shop.I really like @jcdammeyer approach. But I don't want separate boxes and systems. If you believe the motor and hardware are fine, then I'm maybe thinking about replacing the board with a smarter better design.

Did you pitch your power feed hardware when you canned it and went CNC? If not, I'd happily give you some coffee money for the parts......

TorontoBuilder

Sapientia et Doctrina Stabilitas

thanks for expanding on what I was thinking about building last night.It's called an ELS from me... <GRIN> I used an older ELS on my mill knee stepper motor and Gecko drive for years.

Here's the thing. If you buy a standard COTS power feed then that is exactly what you get. If you mount a DC motor and a variable power supply of some sort that's exactly what you get.

Now, if you install some sort of stepper/servo motor that requires step/dir pulses you do need some sort of variable frequency driver for it and it has to have the ability to accelerate so that you don't either lock up the stepper motor or get what is called a servo following error. That means the step pulses arrived faster than the motor could move and the encoder feedback verses step pulses exceeded a difference between the two.

So why install something like that even though you don't want CNC? Because if you did change to CNC it's not an overwhelming change anymore. Instead it's just a module. No mechanical hardware changes.

So back to how I used my knee with the ELS. I could set the lowest point of knee movement to 0. Then just jog it up with the buttons or the MPG knob. Want another 0.010" depth of cut, just adjust it upwards by another 0.010. Want to change a tool or measure? ALT-Z_HOME and down it goes out of the way stopping automatically at that 0.000 point. Change the tool, jog back up and use the paper shim approach to find the surface for the next cut or drilling operation. I used the quill for that all those operations once it was back up because I have the Shumatech DRO-350 on the quill. Not the knee.

I'm actually amazed that the CNC ACORN type modules don't provide a "manual" operation mode. I guess it's because they are so enamored with CNC that once they go that way they question why anyone would use a mill (or lathe) manually. I use my lathe manually. I just like that it stops before it hits the jaws or bores to a fixed depth.

Like my ELS if you have a power feed on the X axis the ability to set BEGIN/END positions and then feed rate means you move to the BEGIN position. Set it. Then jog at the speed you feel comfortable with until it's just right. When the cutter clears the work piece you stop motion. Set the END position. Now Jog X up, return to BEGIN, bring Z down and move Y over half a tool diameter or whatever, and press START. Now you have power feed to an end point. The difference is you don't have to hang over the lever.

And I can say that with experience because that's what I used to do with my standard COTS power feed. Now I do the same thing with the MDI screen with feed rate set, start where I am. G01 Xnn.nn whatever nn.nn is.

Think of it this way. Crap computer shit. Much easier to use that nice clean easy to read slide rule where all the marks are laid out and you can see what the result is, to a couple of decimal places. Or forget the slide rule or the calculator. Notepad and long division is so much more reliable...

heh heh...

so, to clarify. I can use your els I was going to buy just to play with on the knee of my mill instead? I'd want to move the knee in given increments not the quill though.

Former Member

Guest

Stepper Motor Speed and Direction Control Without a Microcontroller

Stepper Motor Speed and Direction Control Without a Microcontroller: In one of my previous Instructables, I showed you how to control a stepper motor's speed using a 555 timer. This project is an upgrade of that one and you will get to know how to control the motor's direction using another 555...

VicHobbyGuy

Ultra Member

plenty of off the shelf stepper programs that will simply run a stepper forward and backwards with variable speeds if you look around.

First you need to decide whether you want to spend your time writing code and messing with programming a computer board OR soldering parts together and wiring up switches.All I need is someone to make a parts list and wiring diagram

Different things entirely. "Been there, done that"; I prefer the latter option.

That's how I used it on my knee. I would post a picture etc. but my main PC wouldn't reboot properly last night. The usual loading windows screen and then black with only a cursor. I suspect it's a virus that prevents access at least based on what I've read on the web.thanks for expanding on what I was thinking about building last night.

so, to clarify. I can use your els I was going to buy just to play with on the knee of my mill instead? I'd want to move the knee in given increments not the quill though.

It's not the hardware because an older 1TB drive boots correctly but it's from 2 years ago. A lot has happened in two years. So I've booted off that and the original drive is a secondary drive. I'm busy copying the various project folders to the server for backup now.

That will take a day or so yet to get everything copied over.

Anyway, I've used my ELS to run my rotary table too. Just set the jog increment so it rotates the table the number of steps for the increment needed. So if I want 32 divisions each jog moves 11.25 degrees. However many stepper motor steps that requires.

Same with the knee. Tell it what the division ratio is for 0.001" and each jog can move that amount. But you still have to run something. When I have photos back I'll dig out one my friend Joe did of his mill with just a DC motor, some reduction belts and chain drive and a DC motor controller. No incremental movement but no cranking by hand either.

That's how I used it on my knee. I would post a picture etc. but my main PC wouldn't reboot properly last night. The usual loading windows screen and then black with only a cursor. I suspect it's a virus that prevents access at least based on what I've read on the web.

I assume you tried the usual bare boot and recovery boot options accessed from the BIOS.

I also assume you are being very careful about what you do and don't copy over.

I like to attach the suspect drive with a USB drive controller and then scan it with some good virus scanner software. I like Norton.