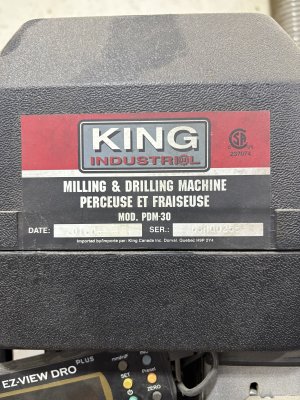

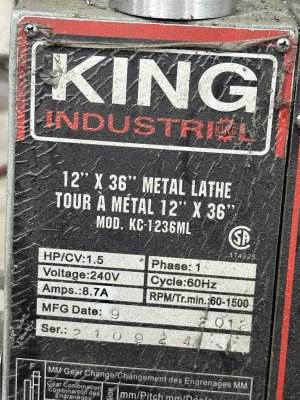

Well as you have clarified, the mill/drill isn't just a drill press. It's also a full blown mill capable of doing complex milling work. Easily worth 1500 as a base machine. But given the peep shot of the lathe tooling, I'd bet he had the mill tooling there to support a two grand or more ask.

Yes. But it isn't just what is in the photo that made me think it's worth a grand. That stuff in the photo implies that he has a lot of other stuff hidden away in drawers or boxes. This is why you need someone experienced to visit and help you sort through things

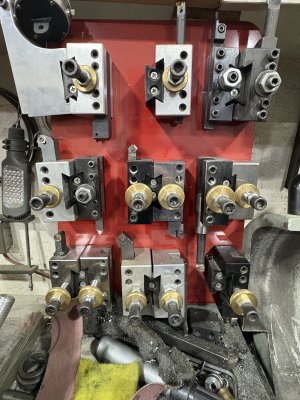

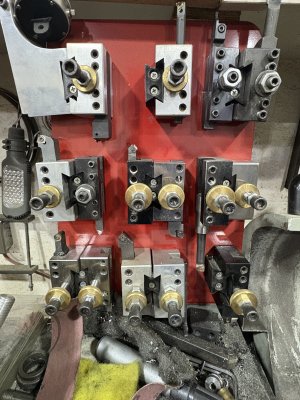

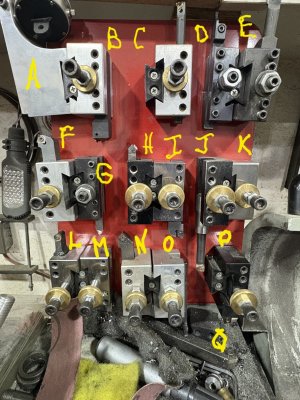

I have taken the liberty of marking up your photo.

View attachment 68466

A - a custom dial gauge holder and dial gauge. This really caught my eye. Your dad had to possess more than basic skills to make that. In fact, I'd bet he made all the tool holders that have brass height adjusting nuts on them.

B - might be a broken tool bit. The photo resolution isn't enough to discern what it is or was. But also could be a parting tool or an upside down threading tool. Given the eclectic nature of some of his other threading tools, I'd guess the latter.

C - An internal threading tool on a custom tool holder. Again suggesting more than basic skills. Novice machinists avoid internal threading like the plague. Someplace he has boxes of inserts and probably more tools.

D - An insert style parting tool.

E - a boring bar of some kind. I can't see the tool bit end so I can't say exactly what it is.

F - A right hand turning facing tool with square insert.

G - A hand ground HSS Turning tool. The tool shape is not book standard. He ground that from his experience not what he learned in a classroom. It's shape and grind suggests a deeper knowledge of the lathe cutting process. He probably has a lot of other HSS Tools in another hiding place.

H - A Carbide Turning tool

I - A right hand carbide insert turning facing tool

J - A mill style Carbide Boring Bar. Most machinists would not normally do this especially when he has other tools to use for that purpose. But it is interesting because it implies that he has a boring head for his mill with a set of carbide boring bars. His use of it on his lathe implies that he had a versatile skill and knowledge set.

K - an empty custom tool holder.

L - a large round insert carbide cutting tool. These are useful to provide nicer left/right turning facing finishes as well as plunge cuts. The fact that has a big one on the board suggests he might have another smaller one in a drawer. Again, a tool that most novice machinists do not have.

M - the steel wool is hiding the tool. But the steel wool also tells me that he likes to produce nice finishes.

N - Another style of left/right turning facing tool.

N - I can't see the tool.

O - Another style of parting tool.

P - A left hand turning facing tool.

Q - appears to be some kind of large boring bar. He must have a holder for it someplace.

In summary, there has to be drawer/drawers of stuff elsewhere. He has a fairly wide set of tools with some of them being used in unconventional ways. It doesn't look he bought a, set of tools, rather that each one was deliberately targeted for a specific use (a wise way to buy tooling). Everything appears to be well used. He was an active accomplished machinist capable of doing a broad range of lathe work. He would have been a good member here.

To make those tool holders, he had to have dovetail tooling for his mill and lots of good metrology equipment.

The scene presents the image of a man with many skills who died suddenly leaving behind a window into his life.

Thanks for the opportunity to visit with him in absentia.