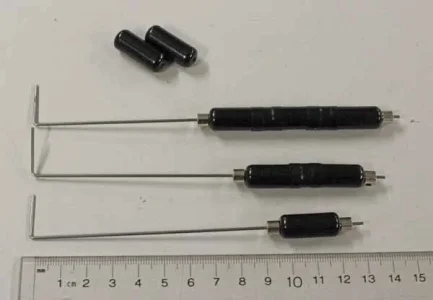

While I was playing with chucks I installed my 8" Atlas chuck (which has an Accusize back plate) and ran it through the entire rpm range. I noted a small vibration that caused my DRO head to quiver at around 800 rpm. That's the same speed as the vibration on the 4 jaw was but I really could not feel it in the machine anywhere but I could see the disturbance in the DRO head. I put the chuck onto the balancer and sure enough there was a distinct heavy spot that would return to the bottom every time. I used masking tape to stick a 7 gram wheel weight to the OD of the chuck and it only took one placed directly opposite the heavy spot to bring the balance to neutral. I really did not want to mess around removing metal from the chuck or backplate so I made up some threaded plugs to fit into some of the threaded holes in the back plate and did some trial and error weight placement. I placed two 5 gram threaded plugs into the threaded holes that house the bolts that hold the chuck to the backplate, bisecting the light spot and achieved a neutral balance. I could have put a 7 gram weight into the large vacant hole in the backplate directly opposite the heavy spot but it is not threaded and it would have been a pain to make something like that. In the pics you can see the heavy spot marked with black sharpie and the 2 M10 X 8mm plugs I made to add weight to the empty part of the threaded chuck mount holes. After mounting the chuck again the small quiver in the DRO head at 800 rpm is gone, cool stuff!