Vintage Gas Pump Guy

Member

Hi Everyone,

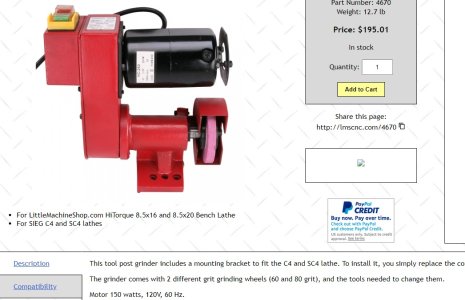

I don't post very much but here goes. I am new to the metal lathe so I am trying to absorb as much information as possible from you guys. I have a small Craftex /BusyBee metal lathe model Craftex B2227L and, would like to mount a tool-post grinder (LittleMachineShop.com model # Part Number: 4670), that I have. I don't really want to start drilling extra holes on the lathe slide. Is there any way to mount this particular grinder to my lathe? Any help would be very much appreciated. Thanks in advance for your time. Kevin

I don't post very much but here goes. I am new to the metal lathe so I am trying to absorb as much information as possible from you guys. I have a small Craftex /BusyBee metal lathe model Craftex B2227L and, would like to mount a tool-post grinder (LittleMachineShop.com model # Part Number: 4670), that I have. I don't really want to start drilling extra holes on the lathe slide. Is there any way to mount this particular grinder to my lathe? Any help would be very much appreciated. Thanks in advance for your time. Kevin