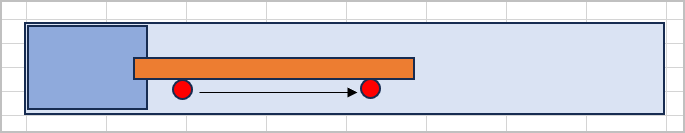

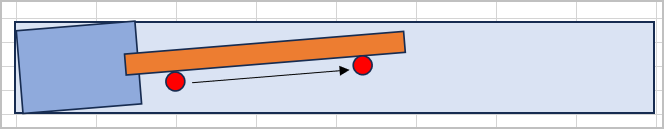

'Sweep' probably means: Attach a DTI to the carriage, ball/plunger contacting the test bar (left red dot). Displace the carriage down the bed, observed DTI readings (at right red dot). IF the bar is seated concentric to the rotation axis and IF its perfectly straight, the it would detect 'something'. That something could be bed twist only, headstock rotation only (viewing from top), bed wear, or some cumulation if all were out. As in post 36, rotation is considered nil on registered headstocks & bed wear would have to be extreme. Twist is the thing we can readily adjust.

But you an probably visualize that everything for this kind of test relies on the test bar geometry & seating/gripping in HS for this specific (idealized) test to work. If its perfectly circular but is banana shaped, all bets are off - its a false reading. Unfortunately this can happen (maybe frequently) with the typical India test bars. I think they might actually be pretty good when new but can stress relive over time & warp. That's what I mean by the banana. Its equivalent to having a hill or bowl in your surface plate topology trying to measure 'flat'. Its just not going to tell you the truth. By grip I mean how is the test bar bar mated to coincide with the rotation axis. If you have it gripped in a chuck & the jaws are off, that's no good. Typically the bars have an MT taper matched to the socket in HS, so the hope is a snug fit delivers a reliable fit. Unfortunately thats not always the case either. Collectively this is why test bars used in this way is kind of frowned upon. The theory is simple, but too many practical 'IFs'.

This subject has been discussed at length previously, search 'bed twist' or 'lathe leveling'

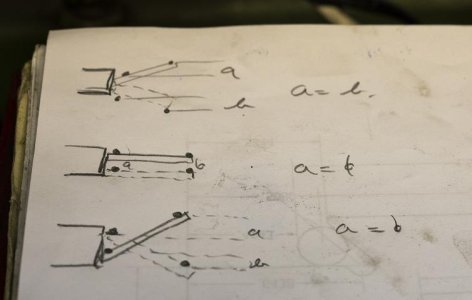

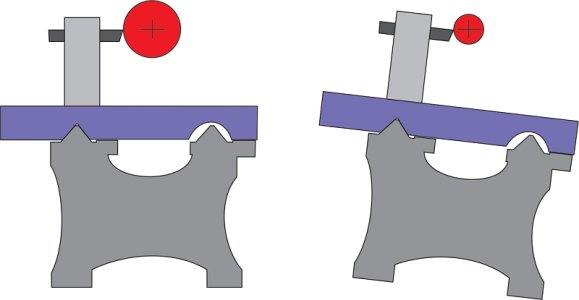

idealized

View attachment 52764

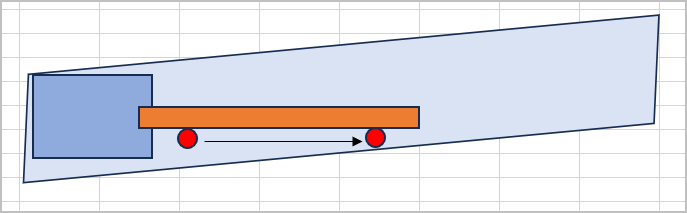

rotated HS

View attachment 52765

(hard to sketch twist, hopefully you can visualize)

View attachment 52766