You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tail Stock lock

- Thread starter Metalistico

- Start date

Metalistico

Member

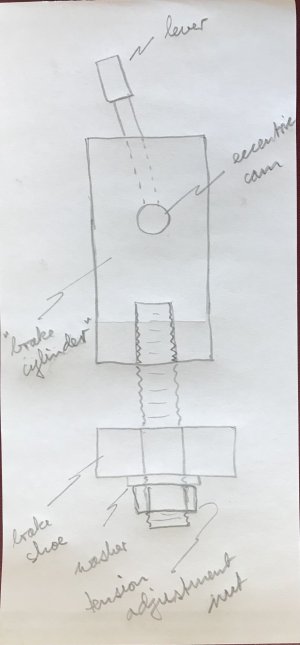

Well with the Mini Lathe you have to tighten the bolt on the tail stock in order to lock it in place, so you need a wrench all the time, so to get rid of hunting down a wrench all the time, i made a sleeve of 3/4" and on the inside of that I have made a threaded 5/8" piston, made a short shaft 1/2" diameter with an offset so when you turn the handle in the back it tightens the tail stock.

Like this? https://littlemachineshop.com/products/product_view.php?ProductID=2018&category=

I just use a dedicated wrench on mine

I just use a dedicated wrench on mine

Like this? https://littlemachineshop.com/products/product_view.php?ProductID=2018&category=

View attachment 19319

I just use a dedicated wrench on mine

Hey Craig, exactly what I use a dedicated stubby metric wrench. Works for us, good enough for me. LOL

Metalistico

Member

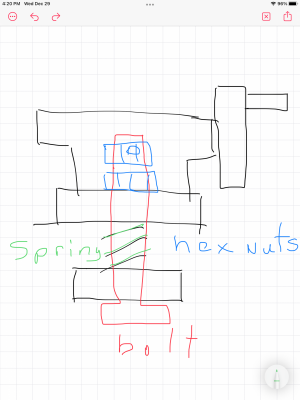

That's exactly the set up I have, except for the bottom washer and nut.You need a way to adjust the pre-tension on your set-up.

It could be done like this:

View attachment 19322

The adjusting nut is used to fine tune the lever movement once the TS is installed on the ways.

I will try in the morning. Thanks

bolt, washer, two hex nuts, cheap CT ratchet wrench. The genius part (if I may say so myself) is a small coil spring between the lock plate and the tail stock housing. never hangs up or drags

Attachments

Metalistico

Member

That's brilliant, I'm gona use this on mine.

Very clever idea. Will have to dig around my spring box for something suitable.The genius part (if I may say so myself) is a small coil spring between the lock plate and the tail stock housing. never hangs up or drags

Thanks for sharing.

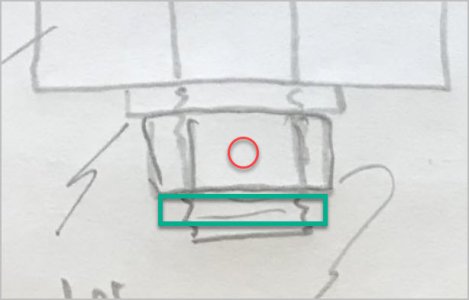

The only issue I have on my TS clamp assembly is the main nut slowly unscrews from the threaded post over time, so it drifts lower & that affects the cam action on the TS tightening handle. I might have enough thread for a second jamb nut principle (green). I also thought about cross drilling a few holes in the nut (red) & using a brass or nylon set screw against the threads. Enough light force to retain, but not enough to bugger. There is probably a M10 or whatever it is nyloc nut out there in the universe for me, but I'd probably have to buy a bag of 25

@whydontu is that the principle of the what looks like a cap screw head in your pic?

@whydontu is that the principle of the what looks like a cap screw head in your pic?

Attachments

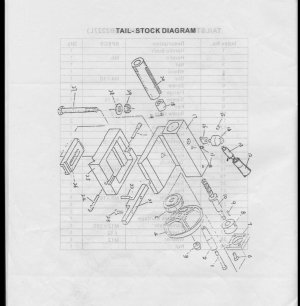

My drawing skills are not able to keep up with my brain. My tailstock lock plate is u-shaped and slotted, item #26. I found a carriage bolt that had a square shank that matched the slot so it slips into the channel and doesn’t rotate. A few minutes with a file was all it took to make the round head of the carriage bolt into a double-d that can slide a bit when I offset the tailstock for tapers. The bolt comes up through #26, #25, and #17. The spring is between #26 & #25. The threaded end of the bolt has two nuts - the lower one is turned by the ratchet wrench, the upper one is cross-drilled and tapped for a lock screw. This means the wrench is captive, nothing turns except the wrench and lower nut.

Attachments

I most probably have one for you. Just confirm the size and I’ll have a look in my stash of metric fasteners.There is probably a M10 or whatever it is nyloc nut out there in the universe for me, but I'd probably have to buy a bag of 25

The genius part (if I may say so myself) is a small coil spring between the lock plate and the tail stock housing. never hangs up or drags

Just installed springs on mine. Works great! Like the ratchet wrench idea to....

Last edited:

I most probably have one for you. Just confirm the size and I’ll have a look in my stash of metric fasteners.

Thank you. Knowing this lathe it could well be IMP so I better check.

I've been meaning to make a new shoe. The stock one doesn't fit the ways properly & the partial rotation movement is probably contributing to the nut problem.

Metalistico

Member

It's a 10 mm, I got 1Once you find out what size it is, let me know.

The only issue I have on my TS clamp assembly is the main nut slowly unscrews from the threaded post over time, so it drifts lower & that affects the cam action on the TS tightening handle. I might have enough thread for a second jamb nut principle (green). I also thought about cross drilling a few holes in the nut (red) & using a brass or nylon set screw against the threads. Enough light force to retain, but not enough to bugger. There is probably a M10 or whatever it is nyloc nut out there in the universe for me, but I'd probably have to buy a bag of 25

@whydontu is that the principle of the what looks like a cap screw head in your pic?

I have this problem on my tailstock too. The nut slowly backs off with use and sooner or later the lock handle won't lock anymore. Sometimes I don't notice it until the tailstock starts moving backward on me. It's never bothered me enough to fix it permanently. I just pull the tailstock off and give the nut a turn or two. It would be nice to be done with that forever with a mod like this.

Thank you!