Stunning how expensive these have become, I think the imported green dial double were a $150 last time I looked. Since then I've accumulated a few mitutoyos, one of which is digital, but that import was surprising good quality...just saying in case one turns up.

I've had to near give away various vernier ones over the years. Your eyes must be good; even with drug store magnifiers, I don't have the patience for verniers.... a dial or digits is so much nicer.

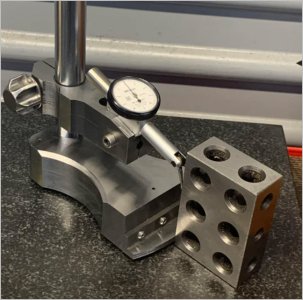

As you point out there is a wide range of levels of accuracy they can be use for, from as good as it gets with an indicator and gauge blocks to scribed lines. We all have our workflows that we like, but imo, generally, the right is way, i.e. the best way, is the quickest method that is good enough for the accuracy required. Sometimes the outside dimensions of a part doesn't much matter and milling/sawing/filing to a scribed line can be quick.

Having said that, I confess my height gauges mostly hold the shelf down, whereas surface gauges get used constantly. similar to what you are saying I think...that surface plate/gauge work tends to shine most brightly with precision stuff.

Where scribed lines can be quite accurate is for hole layout, to with in a couple of thou. You find the intersection with a prick punch or what I do, use an optical centre punch.

Anyway, standard toolaholic rules apply, if you don't have one you badly want/need one

I don't have one...... Yet. I've been looking for ages. No way in hell I'm buying a bargain one. If a bargain one is good enough then I don't really need a surface plate.

My advice is to buy a good one. Don't buy an inexpensive height gauge. If you can't afford a good one new, then resign yourself to waiting for a good used one or a good deal on a new one.

I don't want digital either. I want dial or vernier - preferably vernier. A little bird told me that one is headed my way some day soon. I can wait as long as that might take.

My opinion is that surface plates and height gauges are used to make precision measurements, do measurement comparisons, and calibrate measurement tools and measurement standards - not simple part measurements. They require a level of precision that isn't generally available with inexpensive tools.

The above is a personal opinion. Others are free to disagree.

Edit - I know that a very common use for a height gauge and surface plate is to scribe lines on a part for subsequent machining or layout. I'm not knocking that practice. But to be fair, neither a surface plate or a height gauge is needed to do that. You can even use your mill table, or a piece of flat plate, or even a counter top for that. I don't personally think that a scribed line can be described as a precision measurement. It's a perfectly fine way to measure and make most parts though.

I've had to near give away various vernier ones over the years. Your eyes must be good; even with drug store magnifiers, I don't have the patience for verniers.... a dial or digits is so much nicer.

As you point out there is a wide range of levels of accuracy they can be use for, from as good as it gets with an indicator and gauge blocks to scribed lines. We all have our workflows that we like, but imo, generally, the right is way, i.e. the best way, is the quickest method that is good enough for the accuracy required. Sometimes the outside dimensions of a part doesn't much matter and milling/sawing/filing to a scribed line can be quick.

Having said that, I confess my height gauges mostly hold the shelf down, whereas surface gauges get used constantly. similar to what you are saying I think...that surface plate/gauge work tends to shine most brightly with precision stuff.

Where scribed lines can be quite accurate is for hole layout, to with in a couple of thou. You find the intersection with a prick punch or what I do, use an optical centre punch.

Anyway, standard toolaholic rules apply, if you don't have one you badly want/need one

Last edited: