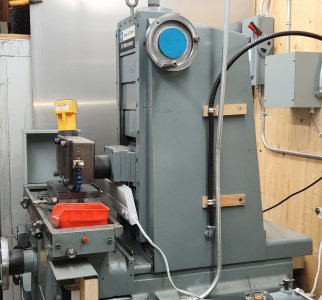

Well, doing a small job this morning with my Brown & Sharpe 612 Micromaster, and the crossfeed handle is sticking, and then getting harder to turn, and then free wheeling and no movement of the table@#$%!

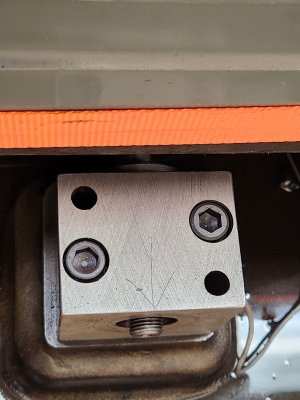

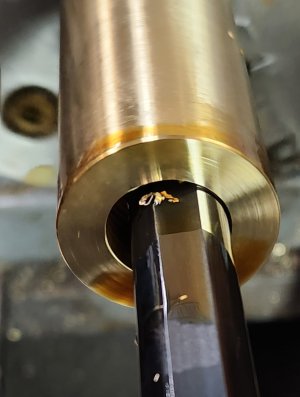

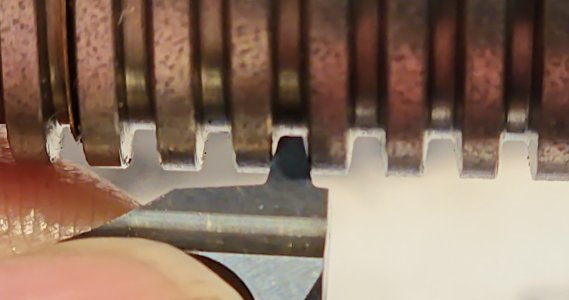

Looks like the bronze crossfeed nut is stripped.

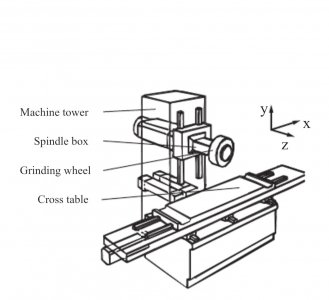

Unlike many surface grinders, the B&S table the z-axis is fixed. The whole spindle, motor, housing, moves. That's a lot of weight that the crossfeed screw has to overcome.

I'll have to get on this soon.

What a pain in the....!!

Looks like the bronze crossfeed nut is stripped.

Unlike many surface grinders, the B&S table the z-axis is fixed. The whole spindle, motor, housing, moves. That's a lot of weight that the crossfeed screw has to overcome.

I'll have to get on this soon.

What a pain in the....!!