-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Still looking for a lathe ! What do you think ?

- Thread starter Titusak

- Start date

mickeyf

Ultra Member

You may be able to find a set of gears on eBay, but I'd check for that first, look at the historical prices, and factor that into what you think the lathe is actually worth - i.e., maybe deduct the cost of the gears from what it would be worth if it came with them. (Plus aggravation value...)

SightlessSeer

Super User

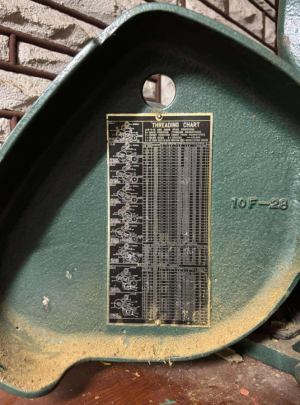

One thing I notice from the new pictures is that there's no drive belt between the countershaft and the spindle, so it probably hasn't been used recently. To put a new one on you either need to disassemble the spindle, or use a link V belt. Also the motor pulley doesn't look like the original one to me. It doesn't really matter, but it will change the speeds that you can use relative to what's listed in the manual (several versions are listed on vintage machinery).

If you have access to, or know somebody who has access to a 3D printer you can find models for the change gears. This was the first one that I found and at a glance they look reasonable. There's an old Mr Pete video where he shows a set of 3D printed Atlas change gears and iirc they worked fine.

www.thingiverse.com

www.thingiverse.com

If you have access to, or know somebody who has access to a 3D printer you can find models for the change gears. This was the first one that I found and at a glance they look reasonable. There's an old Mr Pete video where he shows a set of 3D printed Atlas change gears and iirc they worked fine.

Atlas 10 lathe change gears. by Gadget047

Tumbler gears and change gears for the Atlas 10

make sure it comes with a full set of gears. If not, you will be very limited in cutting threads.

Easy to make any missing ones! In fact, not all lathes can cut all threads. They always seem to miss the one you need next!

Just identify the gear parameters, buy the appropriate gear cutters, and cut your own.

Also, don't assume that your lathe can't cut the thread you want. Sometimes it just isn't on the chart. But you can calculate the missing pitches and fill in the chart.

I guess Im gonna have to learn along the way if I take it @Susquatch, thanks for the tips guys !

Do you guys mind if I do a video and post it here for feedback later ?

Also @mickeyf, yesterday night I checked the video of Blondihacks on youtube. spent the whole night looking at her videos. Simple and effective, that's the way I like it 🙂

I also found this one:

It seems to be the same model. As a beginner, I don't if I'm making the right choice here, but that's the story of my life I think...

Do you guys mind if I do a video and post it here for feedback later ?

Also @mickeyf, yesterday night I checked the video of Blondihacks on youtube. spent the whole night looking at her videos. Simple and effective, that's the way I like it 🙂

I also found this one:

Last edited by a moderator:

As a beginner, I don't if I'm making the right choice here, but that's the story of my life I think...

I like to say it a different way. "The more you know, the more you know you don't know...."

Post away with your video. We love checking stuff like that out.

When I get time, I'm going to make a checklist to help members buying a used lathe. I have posted one already for mills so it only seems appropriate to draft an equivalent one for lathes.

As a beginner, I don't if I'm making the right choice here, but that's the story of my life I think...

I had some time so I thought, no time like now to make a check list for evaluating used lathes. It is just a first draft. I'll update it over time. I posted it here:

https://canadianhobbymetalworkers.com/threads/used-lathe-checkup-list.16034

The only right choice is to get started. There is always going to be something better so if you go in without paying too much you can always cash out and upgrade without remorse.As a beginner, I don't if I'm making the right choice here, but that's the story of my life I think...

I'm going to sell my South Bend now that I have the Meuser, the SB has served me well for several years so no regrets.

The only right choice is to get started. There is always going to be something better so if you go in without paying too much you can always cash out and upgrade without remorse.

I'm going to sell my South Bend now that I have the Meuser, the SB has served me well for several years so no regrets.

This is GREAT advice! Even if you sell the earlier equipment at a loss, it's like low cost rental fees. It's a no brainer to get something to use and learn on instead of waiting forever for the perfect machine.

So, I went to check it, unfortunately, the light in the room break, and the only way to check it was with 2 cellphones flash. So I wasn't really able to take a video....

It is a succession's sell, so the machine hasn't been used in 3 years. From what I was able to check:

- the gears had no tears or defects but the whole set is not here. So there is that.

- The lead Screw Seemed ok, as well as the carriage. No sign of wear, tear, rust.

- The bed had no apparent sign of rust, seemed in pretty good shape.

- The tool post was a bit rusty, and I was not able to say if it was able to hold the tool correctly. Seemed rusty.

- I was not able to determine if it would run on 15A or it was taking 20.

Also, from what I understood, the machine was mostly used with wood. there was wood dust everywhere on the machine, but I guess its easy to clean.

Actually the only concern for me was the fact that I was not able to run it because it was missing belts.

The seller told me he will have someone come tomorrow, to put it back to work, and check is the machine is ok, and make an estimate.

He will then contact me.

One other thing:

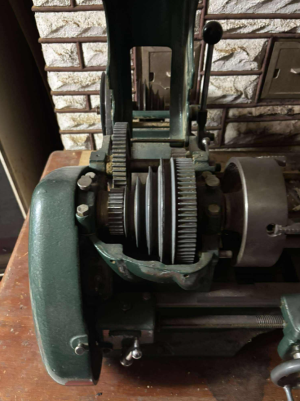

This part here, had cracks, I'm not just if its problematic or not.

Will update you tomorrow guys, but not sure if I should spend more than 500 buck here.

It is a succession's sell, so the machine hasn't been used in 3 years. From what I was able to check:

- the gears had no tears or defects but the whole set is not here. So there is that.

- The lead Screw Seemed ok, as well as the carriage. No sign of wear, tear, rust.

- The bed had no apparent sign of rust, seemed in pretty good shape.

- The tool post was a bit rusty, and I was not able to say if it was able to hold the tool correctly. Seemed rusty.

- I was not able to determine if it would run on 15A or it was taking 20.

Also, from what I understood, the machine was mostly used with wood. there was wood dust everywhere on the machine, but I guess its easy to clean.

Actually the only concern for me was the fact that I was not able to run it because it was missing belts.

The seller told me he will have someone come tomorrow, to put it back to work, and check is the machine is ok, and make an estimate.

He will then contact me.

One other thing:

This part here, had cracks, I'm not just if its problematic or not.

Will update you tomorrow guys, but not sure if I should spend more than 500 buck here.

mickeyf

Ultra Member

Here's someone selling the quick change gear box that is needed:

www.facebook.com

www.facebook.com

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

SightlessSeer

Super User

I wouldn't worry about it running on a regular 15A circuit. Iirc the recommended motor for these machines is a 1/2 HP, which shouldn't be an issue. Even if the one on it is toast, you can generally pick them up pretty inexpensively. The tool holder on it is a lantern style one. They're pretty simple (basically just a bolt), so it will probably hold a tool without any issues, although that being said, you might want to upgrade to a quick change tool post rather than getting into lantern style tooling, just because it's more convenient. The crack in the spindle cone pulley is more concerning, but it's hard to say how serious it is without seeing it, so you might have to make that call yourself.So, I went to check it, unfortunately, the light in the room break, and the only way to check it was with 2 cellphones flash. So I wasn't really able to take a video....

It is a succession's sell, so the machine hasn't been used in 3 years. From what I was able to check:

- the gears had no tears or defects but the whole set is not here. So there is that.

- The lead Screw Seemed ok, as well as the carriage. No sign of wear, tear, rust.

- The bed had no apparent sign of rust, seemed in pretty good shape.

- The tool post was a bit rusty, and I was not able to say if it was able to hold the tool correctly. Seemed rusty.

- I was not able to determine if it would run on 15A or it was taking 20.

Also, from what I understood, the machine was mostly used with wood. there was wood dust everywhere on the machine, but I guess its easy to clean.

Actually the only concern for me was the fact that I was not able to run it because it was missing belts.

The seller told me he will have someone come tomorrow, to put it back to work, and check is the machine is ok, and make an estimate.

He will then contact me.

One other thing:

View attachment 66330

This part here, had cracks, I'm not just if its problematic or not.

Will update you tomorrow guys, but not sure if I should spend more than 500 buck here.

SightlessSeer

Super User

That's a solid deal! if it wasn't on the wrong side of the country from me and I hadn't just bought a bigger lathe I'd be sorely tempted to go after that myself.Here's someone selling the quick change gear box that is needed:

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.www.facebook.com

A half horse power motor is less than a bad vacuum cleaner - just to make the comparisonI wouldn't worry about it running on a regular 15A circuit. Iirc the recommended motor for these machines is a 1/2 HP, which shouldn't be an issue. Even if the one on it is toast, you can generally pick them up pretty inexpensively. The tool holder on it is a lantern style one. They're pretty simple (basically just a bolt), so it will probably hold a tool without any issues, although that being said, you might want to upgrade to a quick change tool post rather than getting into lantern style tooling, just because it's more convenient. The crack in the spindle cone pulley is more concerning, but it's hard to say how serious it is without seeing it, so you might have to make that call yourself.

Ahhh nice ! Thanks you very much !Here's someone selling the quick change gear box that is needed:

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.www.facebook.com

A half horse power motor is less than a bad vacuum cleaner - just to make the comparison

Oh wow, that's a small motor then 😛 might have to upgrade it if necessary ?

SightlessSeer

Super User

You certainly could. My Atlas came with a 1/3 HP motor and I always intended to upgrade it to a 1/2 HP one, but in practice I tend to slip belts before bogging down the motor, so I never bothered. I've read about people putting 1 HP motors on them. That's probably a solid upgradeAhhh nice ! Thanks you very much !

Oh wow, that's a small motor then 😛 might have to upgrade it if necessary ?