After dinner It was coin flip time. Cast the rest of the pieces I need, or machine the 2 good casting I have. I skipped to the good part and fired up the mill.

😀

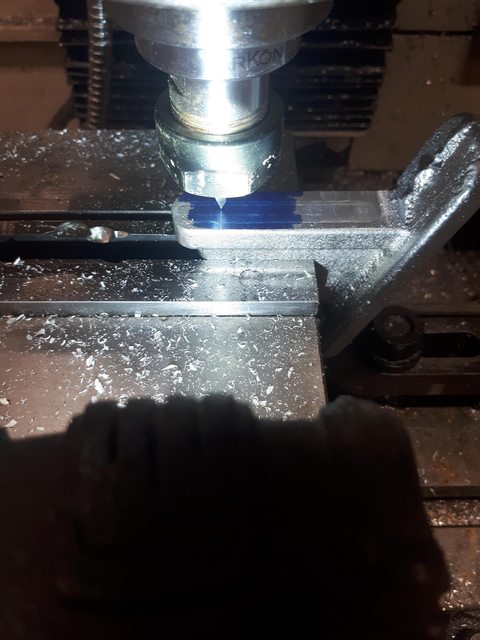

I should have planned this better and left a bit more holding stock for this op. Turned out ok, but I babied it. Used the spindle housing face (

NOT bearing face) to align the lightly clamped part with a parallel, then snugged it down.

I chewed the bulk of it down with a 10mm 3lf, then I licked it clean with a fly cutter (Don't have a face mill for the tormach yet. Maybe my next build????). I picked up the center with an edge finder, and drilled my clearance holes for a #8 woodscrew.

Then I did a repeat of the first op on the angled face. A bit more to hold in this op.

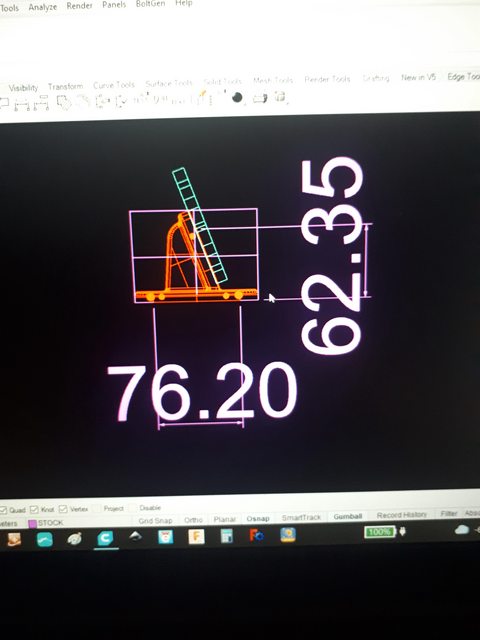

Next was laying out the x location of the 1/4"-20 hole. I snapped a quick pic from cad of the critical dimensions, and layed them out with a caliper and scriber. Then picked up that line with a single lip scriber. There are no really critical dimensions here, so no need to get fancier than this. I retained the y from the previous setup as I was holding the part the same way. Good quick and dirty time saver tip. Save the time and fuss for operations that matter, and you can really speed up your throughput.

All done in the mill, I then tapped the holes with the cordless drill, and countersunk the holes in the drillpress. Clearance is clearance

😀.

Both parts milled it was time to clean up some flash with a flap wheel for the big stuff, and a few different flavours of files.

Done, they looked ugly and rough in the beginning, but cleaned up pretty presentable after a bit of work

😀. I'm kinda curious how they'd come out of the tumbler if they'll fit. I'll try the next set.

y

I brought my newly minted parts in the house to show the wife. She said "cool". Women are so hard to please. Don't you know how many thousands of dollars these brackets cost, woman?

😀

Back out to my shop It didn't take me long to get them put together and mounted on the wall. These should help clean up the mill control area. As you can see I've been temporarily using them for a bit already

😀

I still have 5 more sets to cast and machine (3 racks for each side of the monitor), but I'm pretty happy with the results of a weekends worth of work. I'll chip away at them through the week. A bit more effort and learning on the casting side of things, and I'm really looking forward to what is possible in my little shop now. I could have machined them all from barstock by now, or designed them different, but that wasn't the point of this exercise.

Thanks for following along this for this rambling work in progress. Cheers.